The U.S. market for release control adhesives is witnessing a notable surge, driven by increasing demand across automotive, packaging, electronics, and construction industries. The rising adoption of these specialized adhesives is reshaping manufacturing processes and supply chain dynamics across the nation.

Market Growth Overview

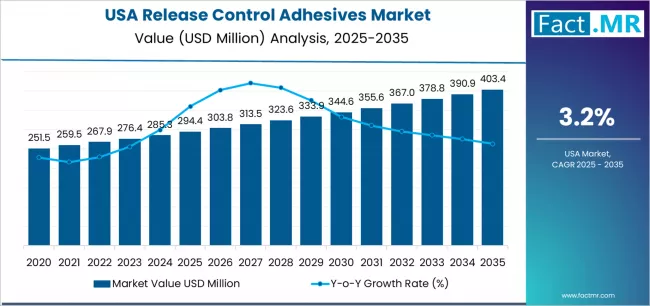

Recent market research indicates that the U.S. release control adhesive market reached approximately $1.45 billion in 2024, representing a compound annual growth rate (CAGR) of 6.7% from 2019 to 2024. Projections suggest that the market could surpass $2 billion by 2030, reflecting continued adoption in both industrial and consumer sectors.

The surge is attributed to increasing applications in automotive interiors, electronics assembly, and industrial laminates, where adhesives that provide controlled release and superior bonding precision are critical. In particular, the packaging sector accounted for nearly 28% of total demand in 2024, reflecting the ongoing growth of flexible packaging solutions and consumer convenience products.

Data Highlights

-

Automotive Sector: Demand for release control adhesives in the automotive industry has grown by 8% year-over-year, driven by innovations in lightweight composite materials and increased use of interior laminates and panels.

-

Electronics & Tech: The electronics segment, including mobile devices and consumer electronics, represented 21% of market consumption, leveraging precise adhesive applications for device assembly and thermal management solutions.

-

Construction & Industrial Use: Use in construction materials such as laminates, sealants, and insulation panels increased by 5.5% annually, underscoring the adhesives’ role in efficiency and durability enhancement.

-

Consumer Goods: The growing preference for eco-friendly and recyclable packaging has driven adhesives tailored for controlled release and easy peel, contributing to 12% growth in 2024 alone.

Technological Drivers

The rise in demand is strongly linked to technological advancements in adhesive formulations, including solvent-free and bio-based adhesives. Bio-based release control adhesives accounted for 14% of U.S. market volume in 2024, up from 10% in 2021, reflecting sustainability trends and regulatory compliance initiatives.

Manufacturers are also investing in precision coating technologies, which allow controlled adhesive release during automated processes, reducing waste and production costs. The adoption of smart adhesives with tunable release profiles is projected to increase by 20% over the next five years, particularly in high-tech applications such as electronics and medical devices.

Regional Insights

The market growth is concentrated in key manufacturing hubs:

-

Midwest & Great Lakes Region: Dominates due to the automotive and industrial manufacturing sectors, accounting for 35% of national demand.

-

West Coast: High technology and electronics manufacturing contribute 27% of consumption, supported by Silicon Valley and surrounding innovation centers.

-

Southeast: Growing packaging and consumer goods sectors drive 18% of demand, reflecting regional supply chain expansions.

Competitive Landscape

U.S. demand is further fueled by both domestic producers and multinational adhesive manufacturers. Leading players such as Henkel, 3M, H.B. Fuller, and Dow continue to innovate in adhesive formulations and release technologies. Market data indicates that the top five players collectively hold over 60% of the market share, signaling a moderately consolidated market with opportunities for specialized and niche product entrants.

Industry Implications

The increase in release control adhesive demand has broad implications for manufacturing efficiency, product innovation, and supply chain resilience. Controlled release adhesives improve assembly speed, reduce material wastage, and enable advanced product designs, directly contributing to cost savings and sustainability goals.

Market analysts note that adoption of automated adhesive application systems could grow by 15% annually, correlating with the broader trend toward Industry 4.0 and smart manufacturing practices. Additionally, stricter environmental regulations are accelerating demand for low-VOC and solvent-free adhesive solutions, reshaping product development strategies.

Quote from Industry Expert

“Release control adhesives are no longer just a supporting material—they’re central to innovation across multiple industries. The U.S. market is seeing remarkable growth as manufacturers prioritize efficiency, precision, and sustainability,” said Dr. Lauren Mitchell, Senior Analyst at Advanced Materials Research Group. “Data-driven insights show that companies investing in high-performance adhesives are gaining a competitive edge in both production and product quality.”

Browse Full Report : https://www.factmr.com/report/united-states-release-control-adhesives-market

Future Outlook

Looking ahead, the U.S. release control adhesive market is projected to expand steadily, driven by:

-

Increased demand in electronics, automotive, and packaging applications.

-

Innovations in bio-based and environmentally compliant adhesives.

-

Expansion of automated application technologies and precision coating systems.

-

Rising adoption of advanced materials requiring controlled-release solutions.

Industry reports suggest the market could grow at a CAGR of 6–7% through 2030, translating to over $2 billion in revenue, while sustainability-focused products are expected to outpace conventional formulations, growing at approximately 10% annually.