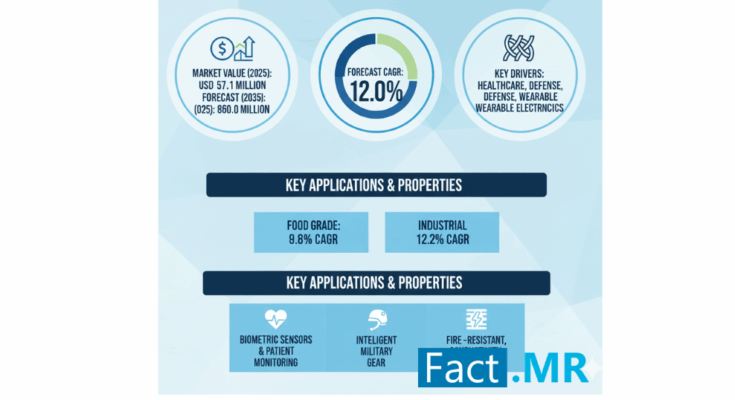

The global Conductive Textile Market is projected to grow from USD 3.1 billion in 2025 to USD 9.6 billion by 2035, registering a CAGR of 12.0%. This growth is driven by the expanding use of conductive fabrics in healthcare, defense, and wearable electronics, where flexibility, conductivity, and seamless electronic integration enable advanced functionalities such as biometric sensors, patient monitoring systems, and intelligent military gear.

Drivers of the Conductive Textile Market

The Conductive Textile Market is experiencing strong momentum from rapid adoption in healthcare, sportswear, automotive, aerospace, and defense sectors. Conductive materials—such as carbon, copper, and silver fibers—are increasingly integrated into traditional fabrics to create smart textiles capable of energy transmission, communication, and biometric sensing.

The surge in wearable technology has become a defining growth catalyst. Consumers’ demand for real-time fitness and health tracking has accelerated the use of conductive textiles that can embed sensors into clothing without compromising comfort or flexibility. These textiles enable continuous monitoring of vital signs—including heart rate, temperature, and muscle activity—driving their adoption in both medical diagnostics and personal wellness applications.

In defense and military, conductive textiles are used in uniforms and gear equipped with energy-harvesting systems, body sensor networks, and integrated communication tools. Government-backed R&D projects in North America and Europe continue to expand their military applications.

Additionally, the automotive and aerospace industries are integrating conductive fabrics into heated seats, interior lighting, and sensor systems to enhance efficiency and reduce weight. In fashion and sportswear, conductive fabrics are enabling the creation of interactive garments that respond to movement or connect with smart devices.

Technological advances in conductive yarns, coatings, and fabric durability are making these innovations commercially viable. Leading players—including DuPont, Toray Industries, Bekaert, and Laird PLC—are forming strategic partnerships with startups and research institutions to expand their smart textile portfolios.

Regional Trends of the Conductive Textile Market

Regional growth in the Conductive Textile Market is influenced by industrial capacity, R&D intensity, and policy frameworks.

The Asia-Pacific region dominates global production, driven by robust textile infrastructure and cost-efficient manufacturing. China, Japan, and South Korea are leading innovators, integrating conductive fibers into healthcare wearables, military uniforms, and automotive applications. China’s Made in China 2025 initiative continues to support investments in high-tech textile production.

North America remains a center of innovation, propelled by defense spending, healthcare adoption, and academic collaborations. The U.S. Department of Defense and major medical institutions are integrating conductive fabrics in smart uniforms and patient monitoring systems, supported by FDA interest in textile-based medical devices.

Europe follows closely, emphasizing sustainable textile production and innovation through R&D programs in Germany, France, and the Netherlands. European manufacturers are aligning with eco-friendly regulations and developing smart textiles for automotive, sportswear, and medical use.

Emerging regions—including Latin America, Africa, and the Middle East—are entering the market through pilot programs in healthcare and military applications, particularly in nations such as Brazil and the Gulf states.

Challenges and Restraints

Despite its promising outlook, the Conductive Textile Market faces hurdles including high production costs and technical challenges related to durability, conductivity, and washability. The use of expensive materials such as silver raises cost barriers for large-scale production.

The absence of standardized testing frameworks, especially in healthcare and defense applications, introduces regulatory uncertainty. Integration with electronic systems also poses technical limitations in maintaining flexibility and long-term conductivity. Additionally, supply chain risks, limited raw material access, and data privacy concerns in wearable technology restrain adoption.

Country-Level Insights

United States:

The U.S. market is expanding rapidly due to strong demand in defense, healthcare, and smart wearables. The Department of Defense remains one of the largest consumers, incorporating conductive textiles in smart uniforms designed for biometric tracking and communication. Collaborations among government agencies, universities, and private companies are advancing research on durable, washable conductive fibers.

China:

China continues to strengthen its global position through large-scale production, automation, and policy-driven innovation. Conductive fabrics are increasingly used in defense uniforms, automotive interiors, and consumer electronics. Government programs promote research in graphene-based materials and nanofiber coatings to enhance conductivity and scalability.

Japan:

Japan’s focus on healthcare, wearable technologies, and robotics is driving its leadership in smart textile innovation. Companies like Toray Industries and Seiren are integrating carbon nanotubes and graphene into fabrics for improved comfort and conductivity. Collaborative projects among universities, startups, and government institutions are accelerating product development in medical textiles and IoT-connected clothing.

Category-Wise Insights

By Product Type:

- Woven conductive textiles dominate due to high strength and consistency, ideal for industrial and defense applications.

- Knitted textiles are the fastest-growing segment, favored in wearable electronics and sportswear for flexibility and comfort.

By Fabric Type:

- Cotton leads due to natural comfort and breathability in skin-contact applications.

- Polyester is expanding fastest, valued for durability and cost-effectiveness in sportswear and military gear.

By End User:

- Military & Defense remains the largest segment, supported by global investments in smart combat textiles.

- Healthcare is the fastest-growing, driven by adoption of biometric monitoring fabrics in patient care and diagnostics.

Regional Leadership

North America holds the dominant market share, supported by R&D infrastructure, defense spending, and medical innovation. Collaboration between technology developers and textile manufacturers continues to strengthen the region’s leadership in advanced smart fabric technologies.

Competitive Landscape and Recent Developments

The Conductive Textile Market is increasingly competitive, with multinational and niche players investing heavily in R&D, customization, and flexible electronics. Key participants such as 3M, Parker Hannifin Corporation, Toray Industries Inc., Laird PLC, and Swift Textile Metallizing LLC are pioneering high-performance materials for EMI shielding, thermal regulation, and electronic integration.

In 2025, Avient Corporation launched non-fluorine stain-resistant additive concentrates under its Cesa™ Fiber Additives line, while showcasing Dyneema woven composites at Chinaplas 2025, emphasizing sustainability and performance in textile innovation.

Segmentation of the Conductive Textile Market

By Fabric Type: Cotton, Nylon, Polyester, Wool, Others

By Product Type: Woven, Non-woven, Knitted, Woolen, Others

By End User: Aviation, Automotive, Healthcare, Military & Defense, Sports & Fitness, Consumer Electronics, Others

By Region: North America, Latin America, Europe, East Asia, South Asia & Oceania, Middle East & Africa

About the Report

This report provides an in-depth analysis of the Conductive Textile Market (2025–2035) based on data from primary interviews, trade sources, and verified industry statistics. The analysis covers growth projections, regional insights, competitive dynamics, and technology trends influencing the adoption of conductive textiles across industries.

Browse Full Report : https://www.factmr.com/report/4274/conductive-textile-market