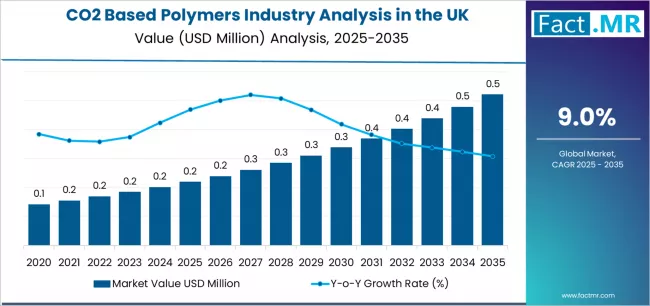

The United Kingdom CO₂-based polymers market is poised for accelerated expansion over the next decade, supported by strengthening environmental regulations, corporate sustainability pledges, and increasing investment in carbon-utilization technologies. According to a latest industry assessment by Fact.MR, the demand for CO₂-based polymers in the UK is projected to grow from USD 0.22 million in 2025 to approximately USD 0.52 million by 2035, reflecting a market value increase of more than 136%, and recording an absolute growth of USD 0.30 million over the forecast period. The market is expected to rise at a CAGR of 9.0% from 2025 to 2035, highlighting strong momentum in carbon-derived material adoption.

CO₂-based polymers, manufactured by incorporating captured carbon dioxide into polymer chains, are emerging as a promising category of low-carbon, partially bio-derived plastics that help industries decarbonize while maintaining material performance.

Browse Full Report: https://www.factmr.com/report/united-kingdom-co2-based-polymers-industry-analysis

Strategic Market Growth Drivers

UK Sustainability Policies Propel Adoption

The UK’s legally backed pathways for carbon reduction, coupled with public-private funding for carbon capture and utilization (CCU), are generating strong incentives for producers to scale CO₂-derived polymer technologies. Government commitments to achieving net-zero emissions by 2050 continue to reinforce the country’s leadership in green chemistry innovation.

Increasing Corporate Investment in Carbon Utilization

Leading UK manufacturers across packaging, automotive, consumer goods, and specialty chemicals are exploring carbon-embedded polymers as part of decarbonization and circular material strategies. Growing emphasis on measurable carbon footprint reduction is driving commercial interest beyond pilot scale.

Rising Demand for Low-Carbon Packaging and Durable Goods

As brands respond to consumer demand for environmentally responsible plastics, CO₂-based polymers are increasingly positioned as alternatives in sustainable packaging, flexible films, rigid containers, and engineered components where reduced emissions are critical.

Advancements in Catalysis and Polymerization Technology

Breakthroughs in catalyst systems, improved CO₂ conversion efficiency, and scalable polymer synthesis are enabling better material properties, higher carbon incorporation rates, and expanded application viability in industrial-grade solutions.

Application Landscape in the UK

- Packaging & Consumer Goods – Early adoption driven by sustainability-focused brands.

- Automotive Components – Use in lightweight, low-carbon interior parts.

- Agriculture & Horticulture – Biodegradable films and coatings with carbon incorporation benefits.

- Construction & Coatings – Durable, partially CO₂-derived polymer binders and finishes.

- Medical & Specialty Materials – High-purity applications under research expansion.

Challenges Influencing Market Scaling

High Production and R&D Costs

Commercial rollout remains cost-intensive due to complex synthesis routes and dependence on advanced catalyst technologies, limiting current adoption to strategic sustainability segments.

Feedstock Integration and Infrastructure Limitations

Polymer producers depend on localized CO₂ capture and purification networks, and uneven CCU infrastructure can impact throughput capacity.

Market Awareness and Performance Validation

Wider industrial penetration requires long-term data validating mechanical performance, biodegradability behavior, and carbon-reduction impact at commercial scale.

Competitive Landscape & Industry Innovation

The UK CO₂-based polymers market is in a formative growth phase, with companies and research institutions prioritizing CCU-enabled polymer development, biodegradable carbon-embedded plastics, and joint industrial collaborations.

Key Entities Driving Progress

- CCU polymer technology innovators

- Sustainable packaging manufacturers

- R&D partnerships between universities and green-chemistry startups

- Carbon-utilization investors and advanced material producers

Stakeholders are focusing on high CO₂ incorporation rates, lifecycle footprint transparency, and commercial partnerships to scale next-generation green polymers.

Milestone Developments

- 2024: Expansion of catalyst systems enabling improved CO₂-polymer conversion efficiency.

- 2023: UK packaging brands begin commercial exploration of carbon-embedded plastics for low-carbon commitments.

- 2022: Academic and startup ecosystems accelerate CO₂ polymer R&D backed by national net-zero targets.

Future Outlook: A Decade of Carbon-Smart Material Transformation

Through 2035, the UK market for CO₂-based polymers is projected to benefit from:

- Expansion of national carbon-utilization infrastructure

- Increased brand demand for low-footprint plastics

- Advancements in catalyst-assisted synthesis

- Rising adoption under circular economy frameworks

- Commercial viability of biodegradable and carbon-embedded polymer grades

As the UK intensifies its focus on carbon reduction and sustainable materials, CO₂-based polymers will play an increasing role in the country’s transition to greener, circular, and climate-aligned industrial value chains.