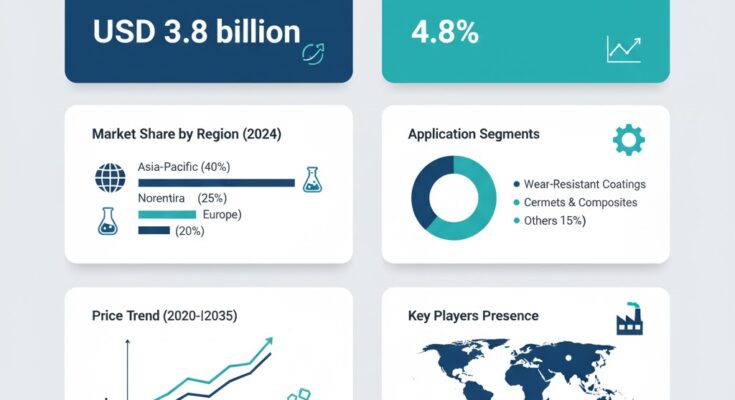

The global chromium carbide market is set for steady expansion, propelled by its increasing use in wear-resistant coatings, thermal spray applications, and high-performance alloy production. Valued at USD 2.4 billion in 2025, the market is forecasted to reach USD 3.8 billion by 2035, recording an absolute increase of USD 1.4 billion over the forecast period. This translates to a compound annual growth rate (CAGR) of 4.8%, according to a recent report by Fact.MR.

As industries worldwide prioritize equipment durability, corrosion resistance, and high-temperature performance, chromium carbide is emerging as a material of choice across energy, aerospace, automotive, and manufacturing sectors.

Market Drivers: Industrial Durability, Thermal Stability, and Coating Innovation

Rising Demand for Wear-Resistant Coatings

Chromium carbide’s exceptional hardness and corrosion resistance make it a critical material in extending the life of machinery and tools. Increasing demand from oil & gas, mining, and metal processing industries for protective coatings is significantly boosting market growth.

Growing Adoption in Thermal Spray and Hardfacing Applications

Chromium carbide is extensively utilized in thermal spray coatings to improve wear resistance and minimize surface degradation. Technological innovations in powder metallurgy and plasma spray systems are enhancing coating quality, further driving market penetration.

High-Temperature Performance and Aerospace Applications

In aerospace and defense, chromium carbide’s ability to withstand extreme environments positions it as an essential component in turbine blades, exhaust nozzles, and other high-temperature parts. The metal’s structural integrity under stress ensures superior operational reliability, spurring demand in this high-precision sector.

Shift Toward Sustainable and High-Efficiency Manufacturing

With the global manufacturing industry shifting toward sustainable production, chromium carbide coatings are being used to reduce equipment maintenance frequency, energy consumption, and material wastage. Emerging nanostructured chromium carbide coatings offer improved toughness and adhesion, representing a key technological advancement for eco-efficient solutions.

Competitive Landscape

The chromium carbide market is moderately consolidated, with major players focusing on product innovation, advanced coating technologies, and regional expansion.

Key Players in the Chromium Carbide Market:

- Oerlikon Metco

- Praxair Surface Tech

- H.C. Starck

- Kennametal

- Saint-Gobain

- Sandvik

- Bodycote

- Fiven

- Materion

- Plansee

- Imphy Alloys

- JX Nippon

- Hunan Goldsky

- HC Starck Tungsten

- Jinzhou Hancheng

These companies are actively investing in R&D, partnerships, and acquisitions to enhance material performance, optimize coating deposition processes, and expand into fast-growing markets such as Asia-Pacific and the Middle East.

Regional Insights

- North America – Dominates the market with advanced metallurgical capabilities and strong demand from aerospace and energy sectors.

- Europe – Focused on sustainability and innovation, with strong regulatory support for industrial efficiency.

- Asia-Pacific – The fastest-growing region, driven by industrial expansion, infrastructure projects, and rising investment in high-performance materials across China and India.

Future Outlook: Toward Advanced, Sustainable Surface Technologies

The next decade will witness rapid advancements in nanostructured chromium carbide coatings, hybrid composites, and automated deposition technologies. The integration of AI and IoT in manufacturing will further optimize coating precision, material utilization, and lifecycle performance.

By 2035, the chromium carbide market is expected to play a pivotal role in modernizing industrial durability and efficiency standards worldwide, aligning with global trends toward sustainable and long-lasting engineering materials.