Radiation cured products are transforming industrial processes by offering rapid curing, high durability, and environmentally friendly solutions. These products, which include coatings, inks, and adhesives, utilize ultraviolet (UV) light or electron beam (EB) radiation to initiate a chemical reaction that hardens or cures materials efficiently. The growing demand across industries such as automotive, construction, electronics, and healthcare underscores the importance of radiation-cured solutions for modern manufacturing.

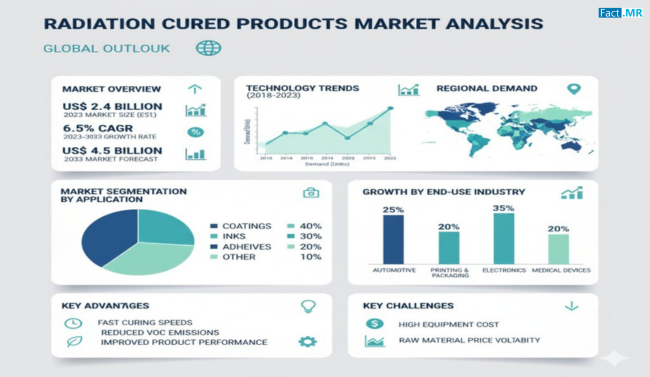

Market Overview:

Radiation curing enables products to solidify quickly without the need for solvents, reducing the emission of volatile organic compounds (VOCs) and hazardous air pollutants. This solvent-free process aligns with increasing sustainability and regulatory requirements, making radiation-cured products a preferred choice for environmentally conscious manufacturers. Their unique properties—such as chemical resistance, adhesion, and mechanical durability—make them ideal for high-performance applications, especially where traditional curing methods are too slow or inefficient.

Regional Insights:

North America and Europe are mature markets with strong adoption in automotive, industrial, and construction sectors. Asia-Pacific is emerging as a major hub, led by countries like China and India. China’s expansive automotive production and India’s growing construction and infrastructure projects are key drivers of demand for radiation-cured products. The region benefits from industrial investments and increasing adoption of UV and EB technologies, positioning it as a global growth engine.

Key Trends & Forecast:

- Rapid Curing Technologies:UV and EB curing enable faster production cycles, increasing efficiency for high-volume manufacturing.

- Sustainability Focus:Radiation-cured products reduce harmful emissions and align with eco-friendly manufacturing initiatives.

- Specialized Applications:Increasing use in automotive, electronics, and construction sectors demands high-performance coatings, inks, and adhesives with superior durability and chemical resistance.

- Digital and Automation Integration:The incorporation of digital platforms and automated processes enhances product consistency and reduces operational costs.

Applications & End-Use Outlook:

The automotive industry is a primary driver, utilizing radiation-cured coatings and adhesives to protect vehicle exteriors, improve aesthetic appeal, and bond lightweight materials like plastics and composites. Electronics manufacturers use these products for protective coatings, circuit board applications, and component assembly. In construction, radiation-cured coatings enhance the durability of surfaces such as metal, wood, and concrete. Healthcare applications include durable coatings for medical devices and equipment, where chemical resistance and fast curing are critical. Packaging, industrial goods, and consumer products are increasingly adopting radiation-cured solutions for improved performance and sustainability.

Market Dynamics:

- Growth Drivers:Expanding automotive production, increasing electronics and construction activities, and rising environmental awareness are fueling demand. Rapid curing, low VOC emissions, and strong adhesion properties make these products essential for modern industrial processes.

- Challenges:High initial investment for UV and EB equipment, and limitations in substrate compatibility (e.g., heat-sensitive plastics or low UV-transparent materials) may restrict market adoption in some sectors.

- Opportunities:Innovation in specialty coatings, adhesives, and inks, along with expanding applications in emerging markets, presents significant growth potential. Collaboration between manufacturers and research institutions is accelerating technological advancements and new product development.

Country-Specific Insights:

China remains a global leader due to high automotive production and demand for lightweight, fuel-efficient vehicles. Radiation-cured products enable effective bonding and surface protection, supporting weight reduction and design flexibility. India’s construction and infrastructure growth, fueled by urbanization and initiatives like the National Infrastructure Pipeline, is driving demand for durable, fast-curing coatings that withstand harsh environments. North America and Europe continue to prioritize high-performance, eco-friendly products for automotive, electronics, and specialty industrial applications.

Category-wise Insights:

Electron beam (EB) curing is gaining traction for its ability to provide rapid and uniform curing, resulting in superior hardness, chemical resistance, and adhesion. UV-cured coatings are highly demanded across automotive, construction, and electronics sectors due to fast drying times, enhanced durability, and environmental benefits. Adhesives and inks using radiation curing offer improved performance, reduced processing time, and compatibility with high-volume production.

Conclusion:

The radiation cured products market is poised for sustained growth as industries seek high-performance, efficient, and eco-friendly manufacturing solutions. From automotive coatings and adhesives to electronics and construction applications, radiation-cured products are central to improving product quality, reducing environmental impact, and enhancing production efficiency. Understanding regional trends, emerging applications, and technological advancements is crucial for businesses aiming to capitalize on this evolving market. Strategic investments in innovation, sustainability, and specialized applications will shape the future of the radiation-cured products market.

Browse Full Report – https://www.factmr.com/report/radiation-cured-products-market