The ceramic membrane market is witnessing strong growth as industries increasingly adopt high-performance filtration systems for water treatment, food & beverage processing, chemical purification, and biotechnology applications. Ceramic membranes, known for exceptional thermal stability, chemical resistance, long lifespan, and high flux rates, are rapidly replacing polymeric alternatives in demanding industrial environments. Growing environmental regulations, water scarcity challenges, and a rising focus on sustainable wastewater management are driving widespread adoption across regions.

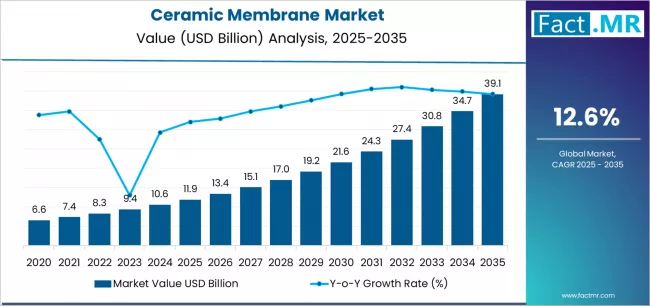

Quick Stats (2025–2035)

-

Market Value 2025: USD 7.2 billion

-

Forecast Market Value 2035: USD 12.9 billion

-

Absolute Growth: USD 5.7 billion

-

Forecast CAGR: ≈ 6.0%

-

Largest Application (2025): Water & wastewater treatment

-

Fastest-Growing Sector: Biotechnology & pharmaceutical filtration

To access the complete data tables and in-depth insights, request a Discount On The Report here: https://www.factmr.com/connectus/sample?flag=S&rep_id=8023

Key Market Drivers

1. Rapid Growth in Water & Wastewater Treatment

-

Industrial and municipal facilities increasingly rely on ceramic membranes for advanced purification due to their high durability and minimal fouling.

-

Tighter environmental regulations regarding effluent discharge are accelerating adoption.

2. Expansion in Food & Beverage Processing

-

Used for clarification, concentration, and sterilization processes in dairy, juice, wine, beer, and edible oils.

-

Ceramic membranes ensure better hygiene, longer operational cycles, and higher efficiency compared to polymeric options.

3. Rising Adoption in Chemical & Petrochemical Industries

-

High-temperature and corrosive environments make ceramic membranes the preferred choice.

-

Applications include solvent recovery, catalyst filtration, and acid/alkali separation.

4. Biotechnology & Pharmaceutical Advancements

-

Increasing use in cell retention, protein separation, fermentation broth clarification, and sterile filtration.

-

Demand is fueled by rising biologics and vaccine production.

Market Segmentation

By Material

-

Alumina (Most Common): Excellent chemical stability and cost-effectiveness.

-

Zirconia: Superior mechanical strength and resistance to extreme pH levels.

-

Titania: Higher permeability and strong thermal resistance.

-

Others: Silica and mixed-oxide membranes for niche applications.

By Technology / Pore Size

-

Microfiltration (largest)

-

Ultrafiltration

-

Nanofiltration (emerging)

-

Hybrid membranes

By End-Use Industry

-

Water & wastewater treatment

-

Food & beverage

-

Chemicals & petrochemicals

-

Biotechnology & pharmaceuticals

-

Mining & metallurgy

-

Power generation and industrial utilities

Challenges

-

High initial capital cost compared to polymeric membranes.

-

Complex production processes increase price sensitivity in developing markets.

-

Fouling risk with certain organic-rich feed streams, requiring effective pre-treatment.

-

Limited penetration in low-budget municipal utilities despite long-term benefits.

Opportunities

-

Decentralized and modular water-treatment systems using ceramic membranes are gaining traction in rural and industrial clusters.

-

Advances in low-cost sintering and 3D-printed ceramic supports will reduce manufacturing costs.

-

Pharma & biotech expansions offer high-margin opportunities for precision filtration membranes.

-

Growing focus on zero-liquid-discharge (ZLD) drives accelerated adoption across chemicals, textiles, and power plants.

-

Oil & gas wastewater treatment emerging as a significant growth avenue.

Outlook (2025–2035)

The ceramic membrane market is projected to grow at around 6% CAGR through 2035, reaching nearly USD 13 billion. Water treatment will remain the largest segment, while biotechnology and pharmaceutical filtration will deliver the fastest growth. With advantages in durability, chemical tolerance, and lifecycle cost savings, ceramic membranes are set to play a crucial role in sustainable industrial filtration over the coming decade. Manufacturers focusing on cost reduction, improved flux rates, and industry-specific membrane modules will capture the most value.

Browse Full Report: https://www.factmr.com/report/ceramic-membrane-market