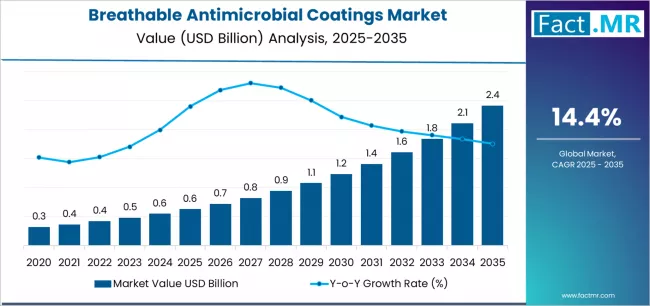

The global breathable antimicrobial coatings market is set to witness accelerated expansion over the next decade, propelled by increasing focus on infection prevention, demand for air-permeable protective surfaces, and rising implementation across healthcare, public infrastructure, textiles, and high-touch industrial environments. According to a new market analysis by Fact.MR, the industry is projected to grow from USD 0.63 billion in 2025 to USD 2.41 billion by 2035, marking an absolute increase of USD 1.78 billion and reflecting a strong CAGR of 14.4% throughout the forecast period.

Growing preference for coatings that combine breathability, microbial resistance, durability, and surface compatibility is rapidly transforming the landscape of functional protective materials worldwide.

Strategic Market Drivers

Healthcare and Public Spaces Fuel Demand for Infection-Resistant, Air-Permeable Surfaces

With heightened awareness around HAIs (hospital-acquired infections) and contamination risks, breathable antimicrobial coatings are gaining traction for their ability to:

- Prevent bacterial and fungal growth

- Allow air and moisture vapor transmission

- Maintain surface integrity without trapping humidity

- Deliver non-toxic and skin-safe protection

Demand is surging in hospitals, clinics, medical equipment, public transportation, classrooms, HVAC ducts, commercial buildings, and shared facilities, where controlled microbial exposure must be balanced with surface breathability.

Browse Full Report: https://www.factmr.com/report/breathable-antimicrobial-coatings-market

Rising Adoption in Functional Textiles & Wearables

The coatings are increasingly applied on sportswear, medical fabrics, upholstery, footwear, face masks, gloves, and compression gear, enabling prolonged antimicrobial performance without impacting airflow or comfort. This is driving higher penetration in both consumer and institutional textile segments.

Urban Infrastructure Focus on Hygienic Touch-Friendly Coatings

Smart city initiatives and expansion of metro stations, airports, malls, and public transport are driving demand for coatings on:

- Door handles, railings, switches

- Seating and wall surfaces

- Escalators, kiosks, and digital touch screens

- Air filtration systems

These coatings help maintain hygiene without creating condensation or humidity buildup on treated surfaces.

Advancements in Coating Chemistry & Nanocomposite Integration

Innovation in nano-silver, copper-based compounds, zinc-oxide composites, self-disinfecting polymers, and porous coating architectures is enabling:

- Longer active life

- Faster microbial kill rates

- Scratch and wash resistance

- Enhanced adhesion on metal, wood, plastic, glass, and fabrics

- Compatibility with IoT-enabled smart surfaces for contamination monitoring

Regional Growth Highlights

North America: Healthcare Prioritization and Commercial Hygiene Standards

North America leads demand owing to extensive investment in healthcare infrastructure, public safety regulations, and innovation in protective materials. The U.S. continues to scale adoption across hospitals, transit systems, and commercial facilities.

Europe: Sustainability Standards and Infection-Prevention Policies

Europe is witnessing rapid uptake driven by EU health protection directives, eco-friendly regulatory frameworks, and adoption in technical textiles and healthcare environments. Countries such as Germany, France, the U.K., and Western Europe are key adopters.

East Asia: Manufacturing and Smart Surface Coating Innovation

China, Japan, and South Korea are major markets driven by:

- Expanding medical device and textile industries

- Government-supported public health safety initiatives

- High adoption of advanced coating nanotechnologies

- Rapid commercialization across home and industrial surfaces

Emerging Markets: Infrastructure Growth and Rising Hygiene Awareness

India, ASEAN, Latin America, and the Middle East are seeing strong growth owing to:

- Expansion of metro networks, airports, hospitals, and manufacturing hubs

- Growth of sportswear and institutional textiles

- Rising demand for anti-odor, anti-fungal, and breathable protective coatings

Market Segmentation Insights

By Coating Composition

- Silver-Based Coatings – Highest adoption due to effective broad-spectrum antimicrobial action

- Copper-Infused Coatings – Increasing use in high-touch public infrastructure

- Zinc-Oxide & Hybrid Nanocomposites – Growing in industrial and textile coatings

- Polymeric Porous Coatings – Strong growth due to breathability advantage

By Substrate Type

- Textile & Fabrics – Largest market share fueled by functional clothing and healthcare textiles

- Metals – Strong adoption in medical instruments and public touch surfaces

- Plastics & Polymers – Consumer electronics, packaging, seating

- Glass & Ceramics – Display panels, tiles, and dashboards

- Wood & Building Materials – Furniture and wall applications

By End-Use Industry

- Healthcare – Fastest-growing segment due to infection control needs

- Textiles & Apparel – High volume driven by comfort-driven antimicrobial fabrics

- Transportation – Railways, buses, aviation surfaces and filters

- Industrial Machinery – Antifungal protection for humid-exposed components

- Consumer Surfaces – Home coatings for air-permeable hygienic protection

- Medical Devices – Imaging, surgical tools, wearable devices

Challenges Impacting Market Growth

Rising Raw Material Costs

Specialty antimicrobial agents and nanocomposites increase formulation costs, restricting adoption in low-margin applications.

Coating Durability vs Breathability Balance

Achieving long-term vapor permeability without compromising adhesion or wash resistance remains a formulation challenge.

Regulatory Compliance for Medical-Grade Coatings

Products targeting healthcare must meet strict EPA, FDA, and international safety approvals, increasing time-to-market.

Competitive Landscape

The global breathable antimicrobial coatings market remains moderately consolidated, with companies emphasizing:

- Breathable nanocoating formulations

- Low-VOC, skin-safe, and non-toxic chemistries

- Smart disinfection layer integration

- Scalable production for healthcare and textiles

- Rare-earth and chemical-free antimicrobial innovations

Key Companies Profiled

- BASF SE

- PPG Industries Inc.

- AkzoNobel N.V.

- 3M Company

- Nanolayer Coating Innovators

- Microban International

- DuPont

- Fisher Scientific Surface Solutions

- Hydrophobic-Breathable Coating Manufacturers

- EV/Healthcare Textile Coating Specialists

Companies are also investing in recyclable antimicrobial agents, self-healing coating layers, and AI-supported contamination tracking surfaces.

Recent Developments

- 2024: Expansion of nano-engineered porous antimicrobial coatings targeting medical-grade touch surfaces.

- 2023: Surge in mass deployment of breathable antimicrobial coatings on medical textiles and protective wear.

- 2022: Global infrastructure projects integrate vapor-permeable antimicrobial coatings to reduce humidity-locked contamination.

Future Outlook: Smart, Safe, and Breathable Surface Protection

Over the next decade, major demand shifts will be powered by:

- Permanent infection-resistant building surfaces

- Growth in clinical and home healthcare textiles

- Public mobility and smart infrastructure expansion

- Emphasis on breathable, non-condensing coatings

- Next-gen nanofiber-compatible coating layers

- Chemical-free and nature-derived antimicrobial solutions

As hospitals, urban infrastructure, textile brands, and industrial equipment manufacturers prioritize hygiene without sacrificing surface airflow, breathable antimicrobial coatings are set to become a foundation technology for healthy, long-lasting protective surfaces through 2035.