The autonomous forklift market is on a rapid growth trajectory as industries around the world — from warehousing and logistics to manufacturing and cold-storage — increasingly embrace automation to improve efficiency, safety, and throughput. Autonomous forklifts are redefining material handling by offering driverless operation, precise navigation, and integration with smart warehouse systems.

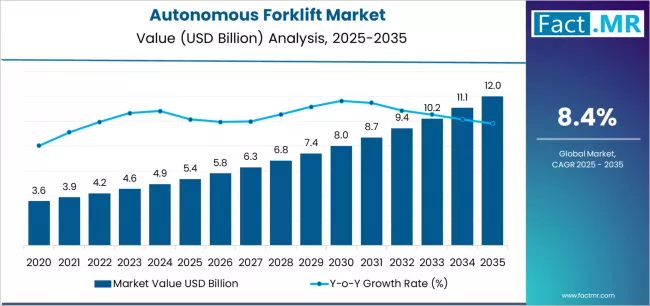

Recent industry analyses estimate that the global autonomous forklift market will grow from a base value of several billions of USD in the mid-2020s to a significantly larger global market by the early 2030s, with strong double-digit annual growth rates.

Key Market Highlights

-

Dominant Forklift Type: Counterbalance forklifts are the most widely adopted autonomous forklift configuration, offering a balance of versatility and load-handling efficiency, particularly suited for general warehouse operations.

-

Leading Navigation Technology: LiDAR-based navigation leads the market owing to its reliable mapping, real-time obstacle detection, and robust performance in varying warehouse conditions.

-

Primary Application: Warehouse automation — including distribution centers, fulfillment facilities, and automated storage systems — accounts for the largest share of demand.

-

Key End-User Industries: Logistics & e-commerce, retail distribution centers, manufacturing, cold-storage & temperature-controlled warehousing, automotive, food & beverage, and general industrial segments.

-

Advantages Driving Adoption: Reduction in reliance on manual labor, improved operational safety, higher productivity and throughput, consistent handling quality, better utilization of warehouse space, and suitability for 24/7 operations.

To access the complete data tables and in-depth insights, request a Discount On The Report here: https://www.factmr.com/connectus/sample?flag=S&rep_id=11877

What’s Driving Market Growth

Rapid Expansion of E-commerce and Fulfillment Needs

As online shopping and fast-delivery expectations grow, fulfillment centers and warehouses are under pressure to process and dispatch orders faster. Autonomous forklifts help meet these demands by enabling round-the-clock material handling, reducing delays, and supporting high-volume throughput with minimal human intervention.

Labor Shortages & Rising Labor Costs

Many regions face labor shortages in warehousing and material-handling jobs, and rising labor costs make manual forklift operations increasingly expensive. Autonomous forklifts provide a path to reducing dependency on labor, lowering long-term operating costs, and mitigating staffing challenges — making them attractive investments for large-scale logistics operations.

Advances in Sensor, Navigation & Automation Technologies

Improved LiDAR, vision-guided systems, SLAM (simultaneous localization and mapping), and robust software for fleet coordination and obstacle avoidance have significantly increased reliability of autonomous forklifts. These technological advances make it feasible to deploy driverless forklifts even in complex warehouse environments.

Demand for Safety, Efficiency & Smart Warehouse Integration

Safety regulations, desire to minimize workplace accidents, and the need for predictable, repeatable operations push companies toward automation. Autonomous forklifts — integrated with warehouse management systems and IoT platforms — enable real-time tracking, optimized routing, load monitoring, and improved space utilization, aligning with modern “smart warehouse” strategies.

Operational Flexibility & 24/7 Capability

Autonomous forklifts can operate continuously — including night shifts or off-peak hours — without human operators, making them ideal for high-volume or time-sensitive operations. Their ability to work in cold storage, hazardous, or controlled environments adds to their appeal across diverse industries.

Challenges & Market Constraints

High Initial Investment & Integration Costs

Deploying autonomous forklifts requires significant upfront investment — in hardware (forklifts, sensors), software, warehouse infrastructure upgrades (racking layout, navigation paths), and system integration. For smaller warehouses or cost-sensitive operators, this capital barrier can limit adoption.

Compatibility with Legacy Infrastructure & Processes

Many existing warehouses use infrastructure, workflows, and racking systems optimized for manual forklifts. Retrofitting these warehouses for autonomous operations (paths, floor plan modifications, safety measures) may require additional investment and downtime.

Technical Complexity & Maintenance Requirements

Autonomous forklifts rely on advanced sensors, navigation algorithms, fleet-management software, and regular maintenance. Efficient operation demands technical expertise, skilled maintenance personnel, and robust support systems — which may be lacking in some regions or smaller operators.

Safety, Standards & Regulatory Compliance

Use of autonomous vehicles in warehouses introduces safety and regulatory considerations — from obstacle detection and collision avoidance to human-worker interaction protocols, certification standards, and liability. These can slow down adoption, especially in regions with evolving regulatory frameworks.

ROI Uncertainty for Low-Volume or Small-Scale Users

For small warehouses, infrequent material-handling needs, or low-volume operations, the cost-benefit balance may not justify switching from traditional forklifts. Lower volume may not offset the high capital cost over a reasonable payback period.

Strategic Recommendations for Stakeholders

For Warehouse Operators & Logistics Firms

-

Begin with phased deployment: pilot autonomous forklifts in high-throughput or 24/7 operations where labor costs, turnover, or productivity demands are highest.

-

Combine autonomous forklifts with human-operated forklifts during transition, to balance flexibility and automation while minimizing disruption.

-

Invest in floor-layout redesign, aisle optimization, and racking configurations conducive to navigation to maximize efficiency gains.

For Manufacturers / Forklift Suppliers / Tech Integrators

-

Focus on adaptable autonomous forklift designs (counterbalance, reach trucks, pallet jacks) with modular navigation systems to cater to varied warehouse types and load requirements.

-

Offer comprehensive integration services — including mapping, fleet-management software, maintenance, and training — to lower barriers to adoption for customers.

-

Emphasize safety, reliability, and compliance with international and regional operational standards to build trust and encourage adoption.

For Industry & Policy Stakeholders

-

Develop standardized safety and operational guidelines for autonomous warehouse vehicles to support widespread deployment while ensuring worker safety.

-

Encourage adoption through incentives, especially for industries under pressure of labor shortages or high turnover, to offset initial investment.

-

Promote workforce transition by upskilling operators and maintenance staff for managing automated fleets — combining human expertise and automation benefits.

Market Outlook — 2035 and Beyond

The autonomous forklift market appears destined for strong, sustained growth over the next decade and beyond. As e-commerce, global supply chains, cold-chain logistics, and automated warehousing expand, demand for reliable, high-efficiency material-handling solutions will rise. Autonomous forklifts — with their improving technology, decreasing cost over time, and clear productivity benefits — are likely to become standard in modern distribution centers, manufacturing plants, retail warehouses, and cold-storage facilities.

For forward-looking logistics operators, warehouse owners, forklift manufacturers, and automation integrators, this represents a significant opportunity. With strategic deployment, investment in infrastructure, and alignment with regulatory and safety standards, autonomous forklifts are poised to become a backbone of future industrial material-handling and warehouse automation systems.

Browse Full Report: https://www.factmr.com/report/autonomous-forklift-market