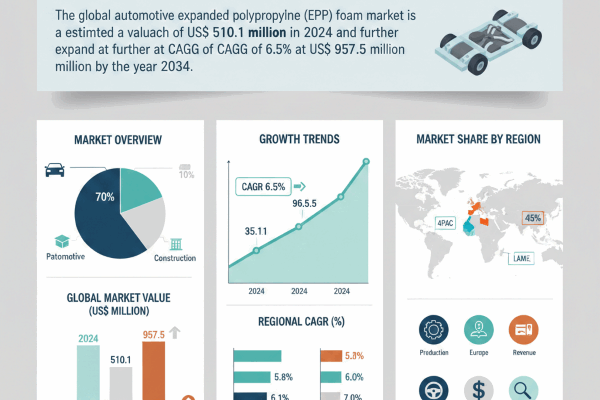

The automotive industry is undergoing a rapid transformation driven by lightweighting, safety enhancement, sustainability goals, and the shift toward electric mobility. Within this evolving landscape, automotive expanded polypropylene (EPP) foam has emerged as a critical material solution. Known for its exceptional energy absorption, durability, recyclability, and lightweight properties, EPP foam is increasingly being adopted across vehicle interiors, exteriors, and powertrain applications. According to industry insights published by Fact.MR, the automotive EPP foam market is positioned for sustained growth as OEMs prioritize material efficiency and performance optimization.

Market Overview

Expanded polypropylene (EPP) foam is a closed-cell bead foam that combines high impact resistance, thermal insulation, and excellent dimensional stability. In automotive manufacturing, it is widely used to reduce vehicle weight while maintaining structural integrity and occupant safety. Unlike traditional foams, EPP offers superior fatigue resistance and can recover its shape after multiple impacts, making it ideal for long-term automotive use.

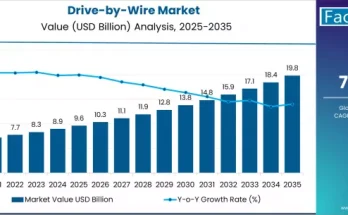

Automakers are increasingly replacing heavier materials such as metal and conventional plastics with EPP foam to meet stringent fuel efficiency standards and emission regulations. Additionally, EPP’s compatibility with complex molding processes allows manufacturers to design multifunctional components, reducing part count and assembly complexity.

Key Growth Drivers

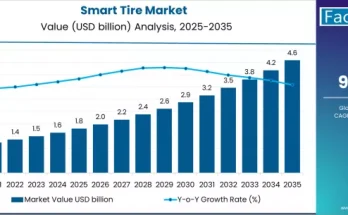

One of the primary drivers of the automotive EPP foam market is the global push for vehicle lightweighting. Reducing vehicle mass directly improves fuel efficiency in internal combustion engine vehicles and extends driving range in electric vehicles. EPP foam contributes significantly to weight reduction without compromising safety or comfort.

Another major growth factor is the rising focus on occupant safety. EPP foam’s superior energy absorption characteristics make it ideal for crash protection components such as bumper cores, headrests, knee bolsters, and door panels. Its ability to withstand repeated impacts enhances vehicle safety over the product lifecycle.

Sustainability is also playing a crucial role. EPP foam is 100% recyclable, aligning with circular economy initiatives and automotive OEM sustainability targets. As environmental regulations tighten worldwide, recyclable materials like EPP are gaining preference over non-recyclable alternatives.

Regional Insights

From a regional perspective, Asia-Pacific dominates the automotive EPP foam market, supported by strong automotive production hubs in countries such as China, Japan, South Korea, and India. The presence of major OEMs, rising vehicle production, and increasing adoption of lightweight materials are key contributors to regional growth.

Europe follows closely, driven by strict emission regulations and advanced vehicle safety standards. European automakers are early adopters of EPP foam for both conventional and electric vehicles, particularly in premium and luxury segments.

North America also represents a significant market, supported by technological advancements, high SUV and EV adoption rates, and increasing investment in lightweight automotive materials. The region’s focus on safety compliance further supports EPP foam integration.

Key Trends and Industry Developments

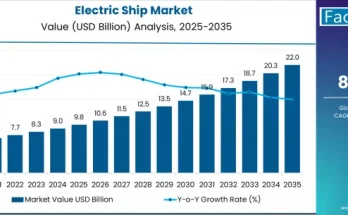

One notable trend in the automotive EPP foam market is its growing use in electric vehicles (EVs). EPP foam is widely applied in battery protection systems, thermal insulation components, and underbody structures, helping safeguard battery packs while reducing overall vehicle weight.

Another emerging trend is the integration of EPP foam in modular automotive designs. OEMs are increasingly using EPP to produce multi-functional parts that combine structural support, insulation, and impact protection in a single component.

Advancements in molding technologies and material formulations are also enhancing the performance characteristics of EPP foam. Improved bead fusion and density control enable customized solutions tailored to specific automotive applications.

Applications and End-Use Outlook

Automotive EPP foam finds applications across a wide range of vehicle components. In interior applications, it is used in headrests, seat cores, armrests, center consoles, and HVAC ducts to improve comfort, noise reduction, and safety.

In exterior applications, EPP foam is commonly used in bumper systems, pedestrian protection components, and energy absorbers due to its high impact resistance. These applications play a critical role in meeting global crash safety regulations.

Under the powertrain and structural category, EPP foam is utilized for tool kits, load floors, spare tire fillers, and battery enclosures, especially in electric and hybrid vehicles. Its thermal insulation properties further enhance its suitability for temperature-sensitive components.

Competitive Landscape

The automotive EPP foam market is characterized by the presence of specialized foam manufacturers and material suppliers working closely with automotive OEMs and Tier-1 suppliers. Companies are focusing on product innovation, lightweight solutions, and sustainable material development to strengthen their market position.

Strategic collaborations, capacity expansions, and investments in recycling infrastructure are increasingly shaping competitive strategies. As highlighted by Fact.MR, manufacturers that offer customized, high-performance EPP solutions are expected to gain a competitive edge.

Conclusion

The automotive expanded polypropylene (EPP) foam market is set to play a pivotal role in the future of vehicle design and manufacturing. Its unique combination of lightweight properties, safety performance, durability, and recyclability aligns perfectly with evolving automotive industry requirements. As OEMs continue to innovate around electric mobility, safety compliance, and sustainability, EPP foam will remain a material of choice across diverse automotive applications. Leveraging comprehensive insights from trusted sources such as Fact.MR can help stakeholders navigate market trends, identify growth opportunities, and make informed strategic decisions.

Browse Full Report – https://www.factmr.com/report/500/automotive-expanded-polypropylene-foam-market