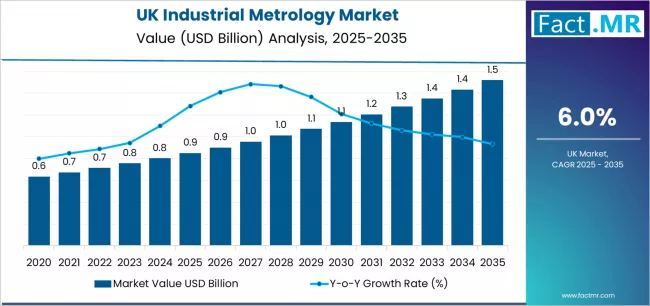

The United Kingdom industrial metrology market is set for steady and sustained growth over the next decade, driven by rising adoption of smart manufacturing practices, stringent quality control regulations, and increasing demand for precision measurement across critical industries. According to a latest analysis by Fact.MR, the market is projected to expand from USD 0.85 billion in 2025 to approximately USD 1.52 billion by 2035, registering a solid compound annual growth rate (CAGR) of 6.0% during the forecast period.

Industrial metrology—encompassing coordinate measuring machines (CMMs), optical digitizers, laser scanners, and automated inspection systems—has become a cornerstone of modern UK manufacturing as companies prioritize accuracy, productivity, and compliance with global standards.

Browse Full Report: https://www.factmr.com/report/united-kingdom-industrial-metrology-market

Strategic Market Drivers

Smart Manufacturing and Industry 4.0 Adoption

The UK’s transition toward Industry 4.0 and digital manufacturing is significantly increasing demand for advanced metrology solutions. Manufacturers are integrating automated inspection, real-time measurement, and digital twins into production lines to minimize errors, reduce waste, and enhance throughput.

Industrial metrology systems play a critical role in:

- Automated quality assurance

- Precision component validation

- In-line and at-line inspection

- Process optimization

Aerospace and Automotive Manufacturing Demand Precision

The UK’s strong presence in aerospace, automotive, and advanced engineering continues to drive adoption of high-precision metrology tools. Tight tolerances, lightweight materials, and complex geometries in aircraft components and EV platforms require non-contact and high-accuracy measurement systems.

Metrology solutions enable manufacturers to:

- Ensure dimensional accuracy

- Meet international safety and compliance standards

- Accelerate product development cycles

Rising Emphasis on Quality Control and Regulatory Compliance

Stringent UK and EU quality standards, including ISO and AS certifications, are pushing manufacturers to invest in reliable measurement and inspection technologies. Industrial metrology supports regulatory compliance across industries such as:

- Medical devices

- Electronics and semiconductors

- Energy and power equipment

As product complexity increases, demand for traceable and repeatable measurement solutions continues to rise.

Advancements in Optical and Automated Metrology

Technological innovations—including AI-enabled measurement software, optical metrology, laser scanning, and robotic inspection systems—are expanding application areas and improving operational efficiency.

Integration with data analytics and manufacturing execution systems (MES) is further enhancing the value proposition of modern industrial metrology.

UK Market Growth Highlights

Strong Manufacturing Base and Innovation Ecosystem

The UK benefits from a well-established manufacturing ecosystem supported by:

- Aerospace and defense clusters

- Automotive and EV production

- Precision engineering SMEs

- Government-backed innovation programs

Investments in advanced manufacturing hubs and digital infrastructure are reinforcing long-term market growth.

Expanding Adoption Across SMEs

Small and medium-sized manufacturers are increasingly adopting portable, automated, and cost-effective metrology solutions to enhance competitiveness and meet customer quality expectations.

Market Segmentation Insights

By Offering

- Hardware – CMMs, optical scanners, laser trackers dominate market share

- Software – Fastest-growing segment with AI-driven analytics and automation

- Services – Calibration, maintenance, and training services gain traction

By Application

- Quality Control & Inspection – Largest segment

- Reverse Engineering – Rising adoption in product redesign and prototyping

- Calibration – Essential for compliance and accuracy

By End-Use Industry

- Aerospace & Defense – High precision and regulatory-driven demand

- Automotive – EV manufacturing and lightweight materials drive growth

- Medical Devices – Accuracy-critical applications

- Industrial Manufacturing – Broad adoption across machinery and tooling

Challenges Impacting Market Growth

High Initial Investment

Advanced metrology equipment requires significant upfront capital, which may limit adoption among smaller manufacturers.

Skilled Workforce Requirement

Operating sophisticated metrology systems demands skilled professionals, creating a talent gap in some regions.

Integration Complexity

Integrating metrology systems with existing production and digital platforms can increase implementation time and costs.

Competitive Landscape

The UK industrial metrology market is moderately competitive, with players focusing on:

- Automation-ready inspection systems

- AI-powered measurement software

- Portable and flexible metrology solutions

- Industry-specific customization

Companies are also investing in training programs and service-based models to expand customer reach.

Future Outlook: Precision at the Core of UK Manufacturing

The next decade will see industrial metrology become an integral part of the UK’s advanced manufacturing strategy, driven by:

- Smart factories and digital twins

- Growth in EVs and aerospace innovation

- Automation and robotics integration

- Rising quality and compliance demands

As UK manufacturers continue to embrace precision, efficiency, and digital transformation, industrial metrology demand is expected to grow steadily through 2035, positioning the market as a critical enabler of high-value manufacturing and global competitiveness.