The industrial tugger market is witnessing robust growth, driven by increasing automation, lean manufacturing initiatives, and growing demand for efficient material handling solutions in warehouses, manufacturing plants, and distribution centers. Industrial tuggers are specialized vehicles designed to tow multiple carts or trailers simultaneously, improving workflow efficiency and reducing labor costs in material transport operations.

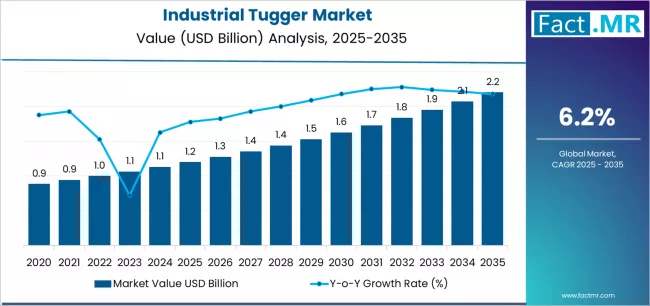

As of 2025, the global industrial tugger market is estimated at approximately USD 1.4 billion, with forecasts projecting growth to around USD 2.5 billion by 2035, reflecting a compound annual growth rate (CAGR) of about 5.9%. Growth is fueled by the rising need for streamlined internal logistics, labor optimization, and enhanced safety in industrial operations across automotive, aerospace, food and beverage, and e-commerce sectors.

Key Market Highlights (2025 Baseline)

-

Market Value (2025): ~ USD 1.4 billion

-

Forecast Value (2035): ~ USD 2.5 billion

-

Forecast CAGR (2025–2035): ~ 5.9%

-

Leading Tugger Type: Electric tuggers (~ 58% share in 2025)

-

Dominant End-Use Segment: Manufacturing (~ 46% share in 2025)

-

High-Growth Application: Warehouse & distribution operations

-

Top Regional Markets: North America, Europe, and Asia-Pacific

To access the complete data tables and in-depth insights, request a Discount On The Report here: https://www.factmr.com/connectus/sample?flag=S&rep_id=11938

Growth Drivers & Market Momentum

Expansion of Automated & Lean Manufacturing Practices

The shift toward lean manufacturing and just-in-time (JIT) operations is driving demand for industrial tuggers that streamline the movement of raw materials, work-in-progress (WIP), and finished goods. Tuggers enhance production efficiency, reduce workflow bottlenecks, and optimize floor space utilization in manufacturing plants.

Rising E-Commerce & Warehouse Automation

The growth of e-commerce and third-party logistics (3PL) has increased the need for efficient intra-facility material movement. Industrial tuggers facilitate faster order fulfillment, reduce reliance on manual labor, and improve operational productivity, supporting demand in warehouses and distribution centers.

Energy Efficiency & Electric Tugger Adoption

Electric tuggers are gaining traction due to lower operational costs, zero emissions, and quieter operation compared to diesel or gas-powered alternatives. Advancements in battery technology, including lithium-ion batteries, have further improved runtime, charging efficiency, and durability, making electric tuggers the preferred choice for modern industrial operations.

Focus on Workplace Safety & Ergonomics

Industrial tuggers reduce manual handling, decreasing the risk of workplace injuries and improving ergonomics. Compliance with occupational health and safety standards is a significant factor driving adoption in manufacturing, logistics, and healthcare facilities.

Regional Market Dynamics

North America and Europe lead the industrial tugger market due to mature manufacturing sectors, advanced warehouse infrastructure, and strong adoption of automation technologies. Asia-Pacific is emerging as a high-growth region, driven by industrialization, expanding manufacturing facilities, and increasing e-commerce penetration in countries such as China, India, and Japan.

Challenges & Market Constraints

-

High Initial Investment: Electric and automated tuggers involve substantial capital expenditure, which may limit adoption by small and medium-sized enterprises.

-

Maintenance & Technical Expertise: Specialized maintenance, battery management, and operator training are required to ensure long-term performance and safety.

-

Competition from Alternative Material Handling Equipment: Forklifts, conveyor systems, and autonomous mobile robots (AMRs) present competition in certain material transport scenarios.

-

Infrastructure Limitations: Older facilities may require modifications or investments to fully integrate tuggers into existing workflow systems.

Strategic Recommendations

For Manufacturers & Suppliers

-

Focus on developing energy-efficient, durable, and ergonomically designed tuggers suitable for various industrial applications.

-

Expand product offerings to include customizable configurations, automated features, and modular towing options.

-

Establish robust service networks to provide maintenance, battery management, and operator training to customers.

For End-Use Industries

-

Incorporate tuggers into lean manufacturing, JIT, and warehouse automation strategies to optimize material flow and reduce labor dependency.

-

Evaluate electric tugger adoption to reduce operational costs, minimize environmental impact, and comply with sustainability goals.

-

Implement training programs to ensure safe and efficient usage, reducing the risk of workplace accidents.

For Investors & Market Entrants

-

Recognize the industrial tugger market as a growing segment within material handling and warehouse automation industries.

-

Explore opportunities in electric and semi-automated tuggers, particularly for high-volume logistics and manufacturing operations.

-

Focus on regions with rising industrialization, e-commerce expansion, and modernization of warehouse infrastructure for high-growth potential.

Market Outlook to 2035

By 2035, the global industrial tugger market is expected to reach approximately USD 2.5 billion, driven by the growth of automated manufacturing, e-commerce warehousing, and demand for energy-efficient material handling solutions. Electric tuggers are anticipated to dominate the market due to superior performance, lower operating costs, and sustainability advantages.

North America and Europe will continue to maintain significant market share, while Asia-Pacific is likely to emerge as the fastest-growing region due to industrial expansion and increasing automation adoption. Manufacturers that prioritize technological innovation, ergonomics, operational efficiency, and after-sales support are expected to gain a competitive edge. With rising focus on productivity, workplace safety, and operational efficiency, industrial tuggers are poised to play an essential role in modern material handling and logistics systems over the next decade.

Browse Full Report: https://www.factmr.com/report/industrial-tugger-market