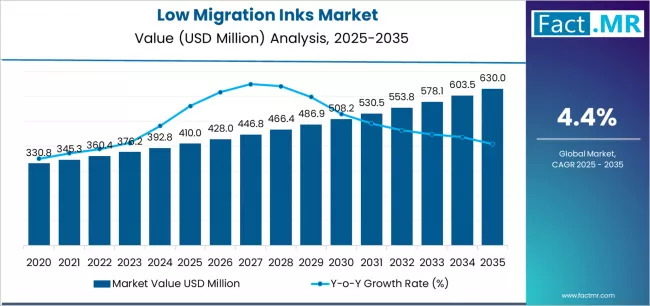

The global low-migration inks market is projected to grow significantly over the next decade, driven by increasing regulatory pressure on food-contact materials, rising awareness of chemical migration risks, and strong demand from food & beverage and pharmaceutical packaging segments. The market is expected to expand from USD 410 million in 2025 to USD 630 million by 2035, reflecting a compound annual growth rate (CAGR) of 4.4%.

Key Market Highlights

-

2025 Market Size: USD 410 million

-

2035 Forecast Value: USD 630 million

-

Projected CAGR (2025–2035): 4.4%

-

Leading Printing Process: Flexography (~35% of the market)

-

Dominant End‑Use Sector: Food & Beverage (~47% share)

-

Key Regions: Asia‑Pacific, Europe, North America

-

Major Players: Siegwerk, Sun Chemical, Flint Group, Huber Group, Agfa‑Gevaert, Henkel, Toyo Ink, INX International, Marabu, Epple

To Access the Complete Data Tables & in-depth Insights, Request a Discount on this report: https://www.factmr.com/connectus/sample?flag=S&rep_id=11637

Five Key Drivers Fueling Market Growth

-

Stricter Food Contact Regulations

Regulatory frameworks for food-contact packaging are becoming more stringent, pushing brand owners and converters toward ink systems that minimize chemical migration into contents. -

Consumer Safety Awareness

Greater consumer consciousness of chemical safety in packaging is driving demand for ink formulations that reduce potential risks related to toxin migration. -

Growth in Flexible Packaging

Flexible food packaging (pouches, sachets, wraps) is widely adopting low-migration inks for direct food contact applications. These inks support both regulatory compliance and consumer safety. -

Digital Printing for Regulated Industries

Digital printing is growing for personalized and short-run applications — especially in pharmaceuticals and nutraceuticals — where low-migration, compliant inks are critical. -

Advances in Ink Chemistry

Innovations in water-based, low-VOC, and migration-tested ink formulations are improving performance, reducing environmental impact, and making compliance more accessible.

Market Segmentation

-

By Printing Process

-

Flexography: The dominant process with ~35% share, widely used in food and flexible packaging.

-

Digital: Makes up a significant portion (~27%) due to its flexibility for variable data and short-run compliance printing.

-

Offset and Gravure: Also used in specialty and high-volume packaging segments.

-

-

By End-Use

-

Food & Beverage: Leading application, especially for flexible food packaging.

-

Pharmaceuticals: A significant segment, driven by strict safety standards for blister packs, labels, and cartons.

-

Personal Care & Other Uses: Includes cosmetics, homecare, and specialty goods where packaging safety matters.

-

-

By Region

-

Asia‑Pacific: Fastest growth expected, driven by manufacturing expansion, food safety investments, and packaging modernization.

-

Europe: Growth supported by strong regulatory standards and a circular economy mindset.

-

North America: Demand is driven by food and pharma packaging, regulatory compliance, and sustainability goals.

-

Challenges & Risks

-

Higher Formulation Costs: Low‑migration inks are typically more expensive than conventional inks, which may discourage adoption among price-sensitive converters.

-

Testing Complexity: Migration verification requires advanced analytical testing, adding cost and technical burden.

-

Supply Chain Constraints: Sourcing of compliant raw materials (resins, pigments) can be challenging for specialized ink systems.

-

Operational Complexity: Converters may need to validate print processes and redesign packaging to meet migration limits.

Competitive Landscape

Key players in the low-migration inks market are prioritizing:

-

Migration‑tested, food-safe formulations

-

Water‑based and low-VOC ink systems

-

Digital low-migration inks for short-run and sensitive applications

-

Global compliance expertise and technical support

-

Partnerships with packaging converters and brand owners focused on food safety

Leading companies such as Siegwerk, Sun Chemical, Flint Group, Huber, Agfa-Gevaert, Henkel, Toyo Ink, INX, Marabu, and Epple are advancing their low‑migration ink portfolios to capture this growing, compliance-driven market.

Strategic Recommendations

-

Invest in Migration Testing Capabilities

Ink makers and converters should scale analytical infrastructure to validate migration compliance and ensure product safety. -

Partner with Packaging Manufacturers

Collaborate with flexible packaging converters and brand owners to co-develop compliant ink solutions tailored for contact applications. -

Educate Customers

Launch training and communication programs for brand owners, packaging engineers, and converters to highlight benefits and compliance risks. -

Expand in High-Growth Regions

Target Asia‑Pacific, where regulatory adoption and food packaging modernization create strong demand for low‑migration inks. -

Focus on R&D for Sustainable Inks

Innovate in water-based, low-VOC, and bio-based low-migration inks to align with sustainability goals and regulatory trends.

Market Outlook

The low-migration inks market is entering a sustained growth phase powered by regulatory demands, consumer safety concerns, and packaging innovation. With the market projected to reach USD 630 million by 2035, low migration inks are becoming a standard requirement for food, pharmaceutical, and specialty packaging.

Ink producers and packaging firms that prioritize safety, compliance, and chemistry innovation will be well-positioned to lead in this critical segment of the packaging value chain.

Browse Full Report: https://www.factmr.com/report/low-migration-inks-market

About Fact.MR:

Fact.MR is a global market research and consulting firm, trusted by Fortune 500 companies and emerging businesses for reliable insights and strategic intelligence. With a presence across the U.S., UK, India, and Dubai, we deliver data-driven research and tailored consulting solutions across 30+ industries and 1,000+ markets. Backed by deep expertise and advanced analytics, Fact.MR helps organizations uncover opportunities, reduce risks, and make informed decisions for sustainable growth.