Sustainability and food safety have become key priorities in the global food processing industry. Pilot-scale solvent recycling plants for food-grade HDPE offer a critical solution, enabling manufacturers to recover high-purity polymers while minimizing environmental impact. These systems allow food processors to reclaim used HDPE packaging, reduce contamination risks, and support regulatory compliance. As environmental regulations tighten and consumer awareness grows, the adoption of advanced solvent recycling technologies is increasing, positioning them as essential infrastructure in modern food-grade operations.

Market Overview

Pilot-scale solvent recycling plants specialize in recovering HDPE for reuse in food packaging applications. These systems utilize continuous, batch, hybrid, or advanced purification processes to separate contaminants, remove residues, and restore polymer quality to food-grade standards. Continuous solvent recovery systems are particularly popular for their precision, efficiency, and ability to handle large volumes with consistent performance.

By combining high recovery rates with regulatory compliance, these plants help food processors and packaging manufacturers maintain product integrity while reducing plastic waste. Innovations in solvent extraction, purification, and quality verification enhance the reliability of recycled HDPE, making it suitable for beverage containers, dairy packaging, and other critical applications.

Regional Insights

North America leads the market, driven by stringent food safety standards, established recycling infrastructure, and government initiatives promoting sustainable packaging. Europe follows closely, with a focus on reducing plastic waste and implementing certified recycling systems across food processing facilities. Asia-Pacific is emerging as a high-growth region, propelled by expanding food manufacturing capacity, rising environmental awareness, and increasing adoption of certified recycling technologies.

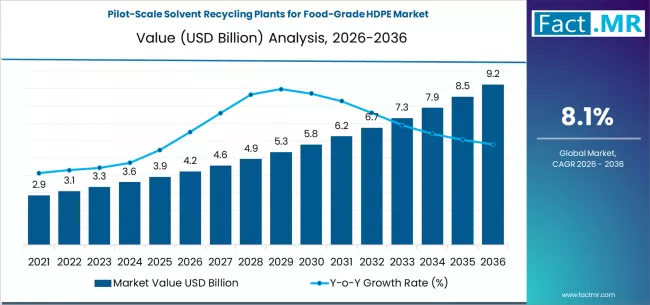

Key Trends & Forecast

The pilot-scale solvent recycling plants market is shaped by several trends:

- Shift Toward Modular and Multifunctional Systems: Manufacturers are deploying modular plants that reduce contamination risks, simplify handling, and support multiple packaging applications.

- Emphasis on Food-Grade Recovery: Systems are increasingly optimized for stringent food safety standards, ensuring recovered HDPE meets regulatory requirements.

- Integration of Advanced Purification Technologies: Continuous advancements in solvent extraction, contaminant removal, and quality monitoring improve recovery efficiency and polymer purity.

- Sustainability and Circular Economy Focus: Recycled HDPE contributes to waste reduction, resource efficiency, and corporate sustainability goals, aligning with global environmental priorities.

- Automation and Digital Monitoring: Smart plant solutions enable real-time monitoring, predictive maintenance, and standardized quality verification across multiple applications.

Applications & End-Use Outlook

Food contact surface recovery is the largest application segment, reflecting the critical need for contaminant-free, high-quality polymers in food processing. Beverage container processing, dairy packaging recycling, and pharmaceutical-grade recovery are also key applications. Food processing facilities represent the primary end-use segment, driven by their focus on hygiene, contamination control, and sustainability. These systems help facilities maintain compliance, optimize material reuse, and reduce operational costs while supporting circular economy initiatives.

Drivers and Restraints

The market is driven by expanding food safety regulations, rising sustainability initiatives, and increasing demand for certified recycling technologies. Food processors are prioritizing systems that offer contaminant reduction, quality assurance, and reliable recovery of HDPE for reuse.

Challenges include the high capital cost of installing pilot-scale recycling plants, technical complexity, and integration requirements within existing processing infrastructure. Overcoming these challenges requires investment in skilled personnel, advanced technology, and regulatory-compliant operations.

Competitive Landscape

Key players in the market include Veolia Environmental Services, Brightmark LLC, Agilyx Corporation, Pyrowave Inc., and Nexus Fuels. Companies are focusing on technology innovation, modular system design, and strategic collaborations with food processors and industrial distributors. Emphasis is placed on enhancing recovery efficiency, minimizing contamination, and ensuring regulatory compliance to differentiate solutions in a growing market.

Country-Specific Insights

The United States is witnessing strong adoption due to expanding food safety infrastructure, regulatory support, and advanced recycling technology initiatives. Germany emphasizes contamination reduction, certified recycling processes, and sustainable packaging practices. Japan is focusing on multifunctional pilot-scale plants that meet strict hygiene standards while enabling material reuse. Across all regions, investments in technology and infrastructure are accelerating market growth and reinforcing environmental compliance.

Conclusion

The pilot-scale solvent recycling plants for food-grade HDPE market is driving sustainable innovation in the food packaging industry. By enabling high-purity polymer recovery, contamination control, and regulatory compliance, these systems support both operational efficiency and environmental responsibility. As technology advances and regulatory pressures increase, pilot-scale solvent recycling plants will play a central role in circular economy initiatives and the long-term sustainability of food processing and packaging operations.

Browse Full Report – https://www.factmr.com/report/pilot-scale-solvent-recycling-plants-for-food-grade-hdpe-market