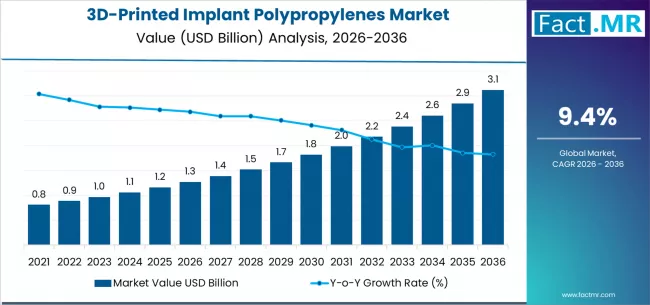

The 3D-printed implant polypropylenes market is witnessing a transformative phase, driven by the convergence of advanced polymer science and additive manufacturing technologies. These implants, designed from medical-grade polypropylene, are increasingly being used in orthopedic, spinal, dental, and craniofacial applications. The market’s growth is fueled by the rising demand for patient-specific implants that enhance surgical precision, reduce recovery times, and offer cost-effective solutions compared to traditional metal-based implants.

Market Overview

3D-printed polypropylene implants combine biocompatibility, mechanical strength, and design flexibility. Medical-grade polypropylene remains the most preferred material, offering a reliable balance of safety, durability, and processability. Innovations in reinforced and surface-modified polypropylene composites have further expanded their application, particularly in load-bearing orthopedic implants. The ability to create anatomically matched, lightweight, and functional components directly from imaging data has revolutionized the approach to personalized healthcare.

Among the implant types, orthopedic implants dominate the market, accounting for the largest share. Custom surgical guides, porous scaffolds for bone ingrowth, and temporary spacers are commonly produced using 3D printing, addressing the growing prevalence of degenerative joint diseases, trauma, and fracture cases. Spinal, dental, and cranio-maxillofacial implants are also gaining traction, reflecting the broader adoption of additive manufacturing across surgical specialties.

Technological Insights

Fused deposition modeling (FDM) is the leading 3D printing technology in this segment, favored for its accessibility, cost-effectiveness, and ability to produce durable, sterile components. FDM facilitates the production of complex geometries with controlled infill densities, enabling lightweight yet strong implants. Other technologies, including selective laser sintering (SLS), multi-jet fusion (MJF), and stereolithography (SLA), are also contributing to the evolution of functional implant design, offering multi-material printing capabilities and enhanced surface finishes.

Advancements in bioactive polypropylene composites, often infused with hydroxyapatite or osteoconductive materials, are enabling implants to support tissue integration and bone bonding. Additionally, multi-material printing allows graded stiffness designs that closely mimic natural tissue, improving patient outcomes.

Regional Insights

North America remains a leading market, driven by a combination of advanced healthcare infrastructure, supportive regulatory frameworks, and widespread adoption of additive manufacturing. Europe follows closely, with increasing investments in medical 3D printing and stringent biocompatibility standards. Asia-Pacific, particularly China, is emerging as a key growth region, propelled by significant investments in healthcare modernization, hospital-based point-of-care manufacturing, and strong expertise in additive manufacturing technologies. The USA, Germany, Japan, and South Korea are also critical players, contributing to market expansion through innovation and increased adoption of patient-specific implants.

Market Drivers

The primary driver of growth is the clinical demand for personalized implants. Customized solutions enhance surgical precision, shorten operating times, and reduce complications. The integration of advanced medical imaging, CAD software, and 3D printing workflows has streamlined the design and production of these implants. Cost advantages of polypropylene over metals like titanium make patient-specific solutions more accessible, while supportive regulatory pathways are simplifying approval processes for additive manufacturing-based medical devices.

Market Restraints

Despite rapid adoption, the market faces certain challenges. Limited long-term clinical data on the performance of 3D-printed polypropylene implants under dynamic load conditions may slow acceptance among surgeons. Post-processing requirements for sterilization and achieving a medical-grade surface finish add complexity to production. Additionally, larger implant production can be time-consuming, and high initial capital investment for industrial-grade medical 3D printers remains a barrier for smaller healthcare providers.

Emerging Trends

Several trends are shaping the market’s future. Hospitals are increasingly adopting point-of-care manufacturing to produce implants on-site, requiring user-friendly and validated polypropylene materials. Real-time sterilization integration during printing is emerging as a critical innovation. The focus on multi-material and bioactive composite printing continues to expand, enabling implants that support tissue growth, mimic natural tissue mechanics, and reduce material usage while maintaining structural integrity.

Competitive Landscape

Leading companies are actively investing in material innovation, technology upgrades, and strategic partnerships to expand their market presence. Key players include 3D Systems Inc., Stratasys Ltd., Evonik Industries AG, BASF (Forward AM), and Arkema S.A. These companies are driving advancements in reinforced polypropylene filaments, surface-modified composites, and additive manufacturing processes, catering to the growing demand for high-performance, patient-specific implants.

Conclusion

The 3D-printed implant polypropylenes market is revolutionizing personalized healthcare by merging additive manufacturing with advanced polymer science. Medical-grade polypropylene offers a reliable, biocompatible, and versatile material base for implants that enhance surgical outcomes and patient recovery. With the ongoing adoption of point-of-care manufacturing, bioactive composites, and multi-material printing technologies, the market is poised to deliver innovative, cost-effective, and highly functional implant solutions worldwide. Stakeholders investing in research, regulatory compliance, and technological advancements are likely to benefit the most as this market continues to expand and redefine the future of patient-specific implants.

Browse Full Report – https://www.factmr.com/report/3d-printed-implant-polypropylenes-market