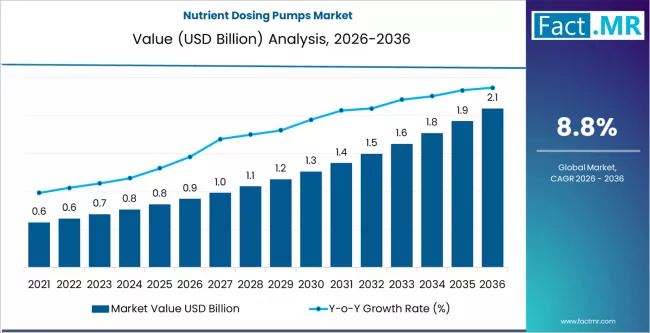

The global nutrient dosing pumps market is entering a phase of rapid technological evolution, with its valuation projected to grow from USD 810 million in 2026 to USD 1.4 billion by 2036. According to specialized industry analysis, the market is set to expand at a compound annual growth rate (CAGR) of 5.7%, fueled by the global shift toward automated fertigation and the rise of high-tech indoor farming.

As commercial growers move away from manual nutrient mixing—which is prone to human error and resource waste—automated dosing pumps have become the backbone of modern crop management. These systems allow for the precise, milliliter-perfect injection of fertilizers, pH adjusters, and supplements directly into irrigation lines, ensuring plants receive the exact nutrient profile required for maximum yield and quality.

Summary Table: Nutrient Dosing Pumps Market Outlook

| Metric | Details |

| Market Value (2026E) | USD 810 Million |

| Forecast Value (2036F) | USD 1.4 Billion |

| Projected CAGR (2026-2036) | 5.7% |

| Leading Product Type | Peristaltic Pumps (38.5% Share) |

| Primary Application | Hydroponics & Soilless Cultivation (45%+ Share) |

| Highest Growth Market | India (8.2% CAGR) |

Request for Sample Report | Customize Report – https://www.factmr.com/connectus/sample?flag=S&rep_id=13644

Core Market Dynamics: Answering the Strategic ‘How’ and ‘Why’

Nutrient dosing pumps are specialized volumetric pumps—typically peristaltic, diaphragm, or piston-based—designed to handle concentrated chemical solutions with high repeatability and corrosion resistance.

-

Who is leading the sector? Industry pioneers including Grundfos, IDEX Corporation, Watson-Marlow Fluid Technology Group, Blue-White Industries, and Dosatron International are at the forefront, developing smart pumps with integrated sensors and IoT connectivity.

-

What is the dominant technology? Peristaltic Dosing Pumps command a significant 38.5% market share. These are favored for their “seal-less” design, which prevents cross-contamination and allows for the easy pumping of abrasive or viscous nutrient thickeners without damaging the pump internals.

-

Where is growth most accelerated? India is emerging as a high-velocity market with an 8.2% CAGR, driven by government incentives for micro-irrigation. China follows with a 7.6% CAGR, supported by the massive industrialization of its greenhouse and vertical farming sectors.

-

Why is the technology shifting? The market is moving toward Digital Integration and Sensor-Feedback Loops. Modern dosing systems are increasingly paired with real-time EC (Electrical Conductivity) and pH sensors, creating a “closed-loop” system that automatically adjusts nutrient delivery based on the real-time needs of the reservoir.

Sector Insights: Hydroponics and Vertical Farming Lead Demand

The Hydroponics and Soilless Cultivation segment is the primary engine of growth, projected to hold over 45% of the market share by 2026. Because these systems have no soil buffer, precise nutrient dosing is critical; even a minor deviation can lead to crop failure. Additionally, the Open-Field Fertigation segment is seeing steady growth as traditional farmers adopt dosing pumps to reduce fertilizer runoff and comply with tightening environmental regulations.

“Precision is the new standard in global food security,” the analysis states. “We are seeing a major trend where ‘Modular Dosing Skids’ are gaining traction. Growers no longer want individual pumps; they want integrated, multi-channel systems that can manage a complex 12-part nutrient recipe from a single smartphone interface. This is the transition from ‘pumping’ to ‘nutrient management as a service’.”

Key Market Trends and Strategic Outlook

1. Optimization through “High-Precision” Micro-Dosing

One of the most significant absolute dollar opportunities lies in Micro-Dosing Systems. As the industry shifts toward high-value crops like medicinal herbs and specialized pharmaceuticals, the ability to dose nutrients at microliter scales with 99% accuracy is becoming a mandatory requirement for premium facility certifications.

2. The Rise of Solar-Powered Dosing Units

Innovation is currently focused on energy autonomy. In emerging markets, manufacturers are launching DC-powered dosing pumps that can run directly off solar arrays. This is a primary growth engine for remote farming operations that lack reliable access to the electrical grid.

3. Regulatory and Sustainability Tailwinds

In the United States (5.5% CAGR) and European Union (5.8% CAGR), growth is supported by “Clean Water” mandates. By using precision dosing pumps, facilities can reduce nitrogen and phosphorus discharge by up to 30%, helping them meet strict ESG (Environmental, Social, and Governance) targets and avoid environmental fines.

Investment Perspective: A High-Utility Agricultural Infrastructure Pillar

The nutrient dosing pumps market represents a robust, recurring revenue opportunity for fluid handling and AgTech firms. As the global population nears 9 billion and arable land becomes scarcer, the demand for scalable, high-efficiency nutrient delivery solutions—capable of maximizing “output per drop”—is expected to remain a primary growth driver through 2036.

Browse Full Report: https://www.factmr.com/report/nutrient-dosing-pumps-market