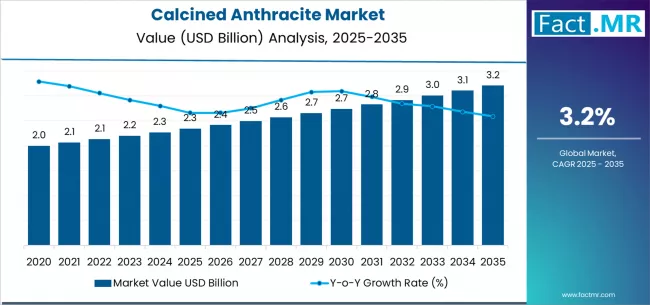

The global calcined anthracite market is poised for steady expansion over the next decade as demand for high-purity carbon additives continues to rise across metallurgical, filtration, and industrial applications. In 2025, the market is valued at USD 2.34 billion, and it is expected to reach USD 3.21 billion by 2035, representing an absolute increase of USD 0.87 billion over the forecast period. This growth reflects a compound annual growth rate (CAGR) of approximately 3.2% between 2025 and 2035, underpinned by rising consumption in aluminum and steel production, enhanced demand for advanced carbon materials, and expanding use in filtration and specialty industrial solutions.

Calcined anthracite is produced by subjecting anthracite coal to high-temperature calcination, resulting in enhanced carbon purity, improved thermal stability, and reduced impurities. These attributes make it a preferred carbon additive in metallurgical processes, including cathode production, recarburization, and other high-temperature applications.

Quick Market Snapshot (2025–2035)

-

Market Value (2025): USD 2.34 billion

-

Market Forecast Value (2035): USD 3.21 billion

-

Market Forecast CAGR: 3.2%

-

Leading Product Grade: Electrically Calcined Anthracite

-

Top Application Segment: Cathode/Carbon Additive in Metallurgy

-

Key Growth Regions: Asia Pacific, Europe, North America

-

Primary End Users: Aluminum producers, steel manufacturers, foundries

To access the complete data tables and in-depth insights, request a Discount On The Report here: https://www.factmr.com/connectus/sample?flag=S&rep_id=9357

Market Overview

Calcined anthracite serves as a vital source of high-carbon material for industries requiring consistent and high-quality carbon inputs. Its application in aluminum production supports cathode and electrode performance, while its use in steelmaking and foundry operations enhances recarburization and metallurgical quality control. Its high carbon content and excellent thermal stability also make it suitable for water filtration and other specialized industrial uses.

Among product grades, electrically calcined anthracite dominates the market due to its superior purity, uniform performance qualities, and broader industrial acceptance. Manufacturers favor electrically calcined grades for demanding applications that require consistent carbon characteristics.

Key Demand Drivers

1. Growth in Aluminum and Steel Industries

As global demand for steel and aluminum continues to grow, driven by construction, automotive, infrastructure, and manufacturing sectors, the need for reliable carbon additives also increases. Calcined anthracite supports enhanced efficiency and quality in high-temperature metallurgical processes, fueling its adoption.

2. Expansion of Advanced Filtration and Industrial Applications

Beyond metallurgical uses, calcined anthracite is increasingly deployed in industrial filtration systems, water treatment solutions, and other applications that benefit from consistent carbon performance. This diversification supports broader market demand.

3. Technological Advancements in Carbon Processing

Improvements in calcination technology and material engineering have enhanced the performance and consistency of calcined anthracite, enabling producers to meet stringent industrial requirements and support specialized applications with tailored performance properties.

4. Regional Industrialization and Infrastructure Growth

Asia Pacific remains a major growth region due to rapid industrial expansion, significant investments in manufacturing infrastructure, and strong demand from heavy industries. Europe and North America also contribute to market growth due to established metallurgy and materials technology sectors.

Market Segmentation Insights

By Product Grade

-

Electrically Calcined Anthracite: Leading segment with the largest market share due to high quality and reliability.

-

Gas Calcined Anthracite: Offers alternative processing advantages and supports specific application needs.

By Application

-

Cathode/Carbon Additive in Metallurgy: Largest application segment driven by aluminum and steel production demand.

-

Recarburizer and Foundry Uses: Supports steelmaking and metal casting operations.

-

Water Filtration and Others: Specialized applications leveraging calcined anthracite’s carbon properties.

By End User Industry

-

Aluminum Production: Key growth driver with increasing demand for high-performance carbon inputs.

-

Steel Manufacturing: Continues to rely on recarburizers and carbon additives for quality improvement.

-

Foundries and Industrial Services: Provide diverse application opportunities.

-

Environmental and Filtration Solutions: Emerging use cases in water and industrial filtration systems.

Regional Demand Outlook

Asia Pacific

Asia Pacific is expected to capture a significant share of the market due to expansive metallurgy sectors and rapid industrialization. Investments in aluminum smelting, advanced steelmaking technologies, and infrastructure expansion support rising calcined anthracite consumption.

Europe

Europe’s established industrial base and stringent quality standards for metallurgy and materials support stable market growth. The region also benefits from technological innovation and material performance research.

North America

North America maintains a steady demand due to its developed steel and aluminum industries, integration of advanced filtration applications, and ongoing material performance improvements that support broader adoption.

Competitive Landscape Overview

The calcined anthracite market features a mix of global and regional carbon material suppliers focusing on product quality, processing capabilities, and customer service. Key players differentiate themselves based on carbon purity, product consistency, and application support — particularly in metallurgical and industrial segments where performance requirements are stringent.

Future Outlook

The calcined anthracite market is expected to maintain steady growth through 2035 as industrial demand for high-quality carbon materials remains strong. Ongoing investment in advanced processing technologies, coupled with expanding applications in metallurgy, filtration, and industrial manufacturing, will support long-term adoption. Manufacturers that innovate in product development, quality assurance, and customer support will be well positioned to capture emerging opportunities and address evolving industrial needs.

Browse Full Report: https://www.factmr.com/report/calcined-anthracite-market