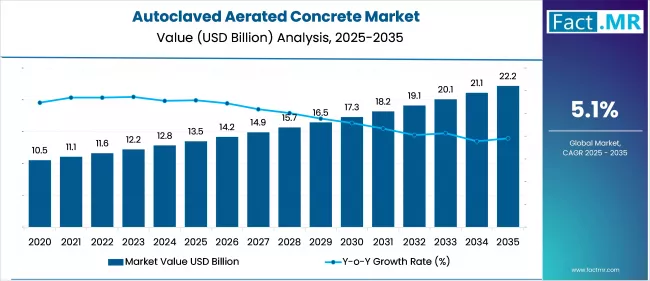

The global construction industry is undergoing a significant shift toward sustainable, energy-efficient, and cost-effective building materials. Among these, autoclaved aerated concrete (AAC) has emerged as a preferred solution due to its lightweight structure, thermal insulation properties, and environmental benefits. As urbanization accelerates and green building practices gain traction, the autoclaved aerated concrete market is witnessing steady expansion across residential, commercial, and infrastructure projects. Insights from Fact.MR highlight that the growing emphasis on sustainable construction and efficient building technologies is driving increased adoption of AAC worldwide.

Market Overview

Autoclaved aerated concrete is a precast, foam concrete building material produced using cement, lime, sand, water, and an expansion agent. The material undergoes curing in high-pressure autoclaves, resulting in a porous structure that offers excellent strength-to-weight performance. AAC is widely used in blocks, panels, lintels, floors, and wall systems, making it a versatile choice for modern construction.

The market for AAC is strongly influenced by its advantages over traditional construction materials, such as reduced structural load, faster construction timelines, and superior thermal and acoustic insulation. Builders and developers increasingly prefer AAC to meet evolving building codes, energy efficiency standards, and sustainability goals.

Key Growth Drivers

One of the key drivers of the autoclaved aerated concrete market is the growing demand for energy-efficient buildings. AAC’s excellent insulation properties help reduce heating and cooling requirements, contributing to lower energy consumption and operational costs.

Rapid urbanization and infrastructure development, particularly in emerging economies, is another major factor supporting market growth. AAC enables faster construction with reduced labor requirements, making it well-suited for large-scale housing and commercial projects.

Environmental sustainability is also playing a crucial role. AAC is considered an eco-friendly building material due to its lower raw material consumption, recyclability, and reduced carbon footprint compared to conventional concrete. Governments and regulatory bodies promoting green construction practices further encourage AAC adoption.

Regional Insights

From a regional perspective, Asia-Pacific represents a dominant market for autoclaved aerated concrete, driven by large-scale residential construction, smart city initiatives, and infrastructure investments in countries such as China, India, and Southeast Asian nations. The availability of raw materials and increasing awareness of AAC benefits support market expansion in the region.

Europe holds a significant share of the AAC market due to long-standing adoption of energy-efficient construction methods and strict building regulations. AAC is widely used in both residential and commercial projects across the region, particularly in low-rise and mid-rise buildings.

North America is witnessing growing interest in AAC as builders seek sustainable alternatives to traditional construction materials. Increased focus on green building certifications and energy-efficient housing is expected to support market growth in the region.

Key Trends & Forecast

A prominent trend in the AAC market is the rising adoption of prefabricated and modular construction techniques. AAC panels and blocks are increasingly used in off-site construction, enabling faster project completion and improved quality control.

Another key trend is the technological advancement in AAC manufacturing processes. Manufacturers are investing in automated production lines, improved curing techniques, and enhanced quality control systems to improve product consistency and performance.

The market is also witnessing increased application diversification, with AAC being used in non-residential structures such as schools, hospitals, industrial buildings, and warehouses. Its fire resistance and sound insulation properties make it suitable for safety-sensitive environments.

Applications & End-Use Outlook

Autoclaved aerated concrete is widely used in residential construction, particularly for walls, partitions, and flooring systems. Its lightweight nature reduces foundation requirements and supports cost-effective housing development.

In commercial buildings, AAC is used for exterior walls, firewalls, and load-bearing components. The material’s thermal efficiency and acoustic insulation enhance occupant comfort while supporting energy efficiency targets.

AAC also finds applications in industrial and institutional buildings, including factories, educational institutions, and healthcare facilities. Its durability, fire resistance, and ease of installation make it an attractive option across diverse end-use segments.

Infrastructure projects, such as bridges and public facilities, are gradually incorporating AAC for non-load-bearing components, further expanding the market’s scope.

Competitive Landscape

The autoclaved aerated concrete market consists of established building material manufacturers and regional producers focusing on capacity expansion and product innovation. Companies are emphasizing quality improvement, cost optimization, and sustainable production practices to strengthen their competitive position.

Strategic initiatives such as new plant installations, partnerships with construction firms, and investments in research and development are shaping the competitive landscape. As highlighted by Fact.MR, manufacturers that offer consistent quality, technical support, and compliance with regional building standards are better positioned to capture emerging opportunities.

Conclusion

The autoclaved aerated concrete market is poised to play a critical role in the future of sustainable construction. Its lightweight structure, energy efficiency, and environmental advantages align well with global trends toward green building and rapid urban development. As construction practices evolve and regulatory frameworks increasingly favor sustainable materials, AAC is expected to witness wider adoption across regions and applications. Leveraging detailed market insights from trusted sources such as Fact.MR can help stakeholders identify growth opportunities and make informed strategic decisions in this evolving construction materials market.

Browse Full Report – https://www.factmr.com/report/508/turbidity-equipment-market