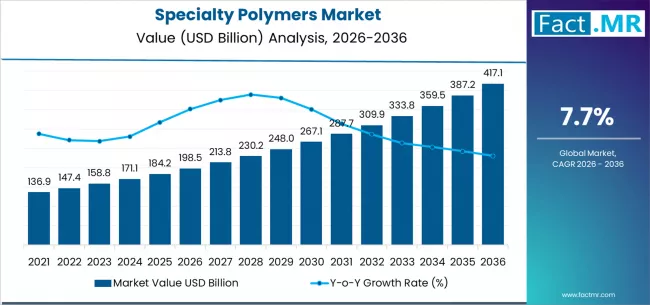

The global specialty polymers market is set for strong, long-term expansion, driven by rising demand for high-performance, lightweight, and durable materials across automotive electrification, electronics manufacturing, healthcare, and advanced industrial applications. According to a recent analysis by Fact.MR, the market is projected to reach USD 417.10 billion by 2036, up from USD 198.45 billion in 2026, reflecting a 2.1x growth over the assessment period. This expansion represents a robust CAGR of 7.7%, underlining the increasing importance of specialty polymers in next-generation technologies.

Growing emphasis on electric vehicles (EVs), miniaturized electronics, sustainability, and high-temperature-resistant materials is accelerating global adoption of specialty polymers.

Browse Full Report: https://www.factmr.com/report/specialty-polymers-market

Strategic Market Drivers

Automotive Electrification Accelerates Polymer Innovation

The global transition toward electric and hybrid vehicles is significantly boosting demand for specialty polymers due to their:

- Lightweight properties supporting vehicle range extension

- High thermal and chemical resistance

- Electrical insulation capabilities

- Design flexibility for complex EV components

Specialty polymers are increasingly used in battery housings, connectors, wire insulation, charging systems, and power electronics, making them essential to modern automotive platforms.

Electronics & Semiconductor Manufacturing Drive High Demand

Rapid growth in consumer electronics, semiconductors, and advanced circuit manufacturing is fueling the need for polymers with:

- High dielectric strength

- Flame retardancy

- Dimensional stability

- Resistance to extreme temperatures

Applications span printed circuit boards (PCBs), flexible electronics, microchips, connectors, and protective coatings, particularly as devices become smaller and more powerful.

Sustainability and Regulatory Push Toward Advanced Materials

Governments and industries worldwide are prioritizing sustainable, recyclable, and energy-efficient materials, prompting manufacturers to adopt specialty polymers that:

- Reduce material usage through high performance

- Enable longer product lifecycles

- Support lightweighting and emissions reduction

Bio-based and recyclable specialty polymers are gaining strong traction, especially in Europe and North America.

Expanding Industrial & Healthcare Applications

Specialty polymers are seeing increased use in:

- Medical devices and implants

- Pharmaceutical packaging

- Industrial coatings and adhesives

- Oil & gas and chemical processing equipment

Their superior resistance to chemicals, wear, and sterilization processes makes them indispensable in critical environments.

Regional Growth Highlights

North America: Innovation and High-End Manufacturing Leadership

North America remains a key market, supported by strong R&D investments, advanced electronics manufacturing, and rapid adoption of EVs and aerospace technologies. The U.S. continues to lead in specialty polymer innovation and commercialization.

Europe: Sustainability Regulations Propel Market Growth

Strict environmental regulations, aggressive EV adoption targets, and emphasis on recyclable and bio-based materials are driving specialty polymer demand across Germany, France, the U.K., and Nordic countries.

East Asia: Electronics and Automotive Manufacturing Hub

China, Japan, and South Korea dominate consumption due to their leadership in:

- Semiconductor fabrication

- Consumer electronics production

- EV and battery manufacturing

Strong government support for advanced materials further accelerates market growth.

Emerging Markets: Industrialization and Infrastructure Expansion

India, Southeast Asia, Latin America, and the Middle East are witnessing rising demand driven by:

- Expanding manufacturing bases

- Growth in electronics assembly

- Automotive production increases

- Infrastructure and energy projects

Market Segmentation Insights

By Polymer Type

- Engineering Plastics – Largest share due to mechanical strength and heat resistance

- High-Performance Polymers – Fastest growth in aerospace, EVs, and electronics

- Fluoropolymers & Specialty Elastomers – Strong demand in chemical and medical applications

By Application

- Automotive – Rapid growth driven by EV electrification

- Electronics & Electrical – High-volume demand for insulation and miniaturized components

- Industrial – Coatings, adhesives, and equipment protection

- Healthcare & Medical Devices – Rising use in implants and diagnostics

- Aerospace & Defense – Lightweight and high-temperature materials

Challenges Impacting Market Growth

High Production Costs

Specialty polymers require complex manufacturing processes and advanced raw materials, resulting in higher costs compared to conventional plastics.

Raw Material Price Volatility

Dependence on petrochemical and specialty feedstocks exposes manufacturers to supply chain and pricing risks.

Recycling and End-of-Life Complexity

Some high-performance polymers pose challenges in recycling, pushing the industry to invest in circular economy solutions.

Competitive Landscape

The specialty polymers market is moderately consolidated, with key players focusing on:

- Product innovation

- Sustainable and bio-based polymers

- Lightweight solutions for EVs

- High-temperature and electrically resistant materials

Key Companies Profiled

- BASF SE

- Dow Inc.

- DuPont

- Solvay S.A.

- Arkema

- Evonik Industries

- SABIC

- LANXESS

- Celanese Corporation

- Covestro AG

Recent Developments

- 2024: Launch of recyclable and bio-based specialty polymers for EV and electronics applications

- 2023: Major automotive OEMs expand use of high-performance polymers to reduce vehicle weight

- 2022: Electronics manufacturers adopt advanced polymer insulation to support miniaturization trends

Future Outlook: High-Performance Materials Shape the Next Decade

The specialty polymers market is poised for sustained growth through 2036, supported by:

- Rapid EV and battery technology expansion

- Miniaturization of electronic components

- Demand for sustainable and recyclable materials

- Growth in medical and aerospace applications

- Continuous innovation in polymer chemistry

As industries increasingly require lightweight, durable, and high-efficiency materials, specialty polymers will remain at the core of technological advancement worldwide.