Lithium-ion battery binders are critical components in battery manufacturing, providing mechanical stability, electrochemical performance, and adhesion for electrode materials. As demand for electric vehicles (EVs), renewable energy storage, and consumer electronics continues to rise, the lithium-ion battery binders market is witnessing rapid growth. These binders—including polyvinylidene fluoride (PVDF), carboxymethyl cellulose (CMC), styrene-butadiene rubber (SBR), and polymethyl methacrylate—play a pivotal role in enhancing battery longevity, cycle life, and overall performance, ensuring reliability across high-energy applications.

Market Overview

Battery binders are polymers that hold electrode particles together and adhere them to the current collector, maintaining structural integrity during repeated charge-discharge cycles. Modern lithium-ion battery binders not only provide mechanical support but also contribute to electrochemical stability, thermal resistance, and safety. With the ongoing push for higher energy density and longer-lasting batteries, manufacturers increasingly focus on advanced binder formulations that deliver superior performance with minimal processing complexity.

Market Growth and Trends

The lithium-ion battery binders market is expanding steadily due to rising EV production, adoption of renewable energy storage systems, and the electrification of consumer electronics. The cathode segment dominates the market, reflecting high adoption of specialized binders optimized for high-energy applications. Meanwhile, anode binders, particularly water-based CMC and SBR formulations, are gaining traction for their environmental compatibility and adaptability to emerging electrode materials.

Key trends include:

- Shift toward water-based binder formulationsfor sustainable and eco-friendly battery production.

- Integration of binders with high-nickel cathodes and silicon anodesto enhance energy density and cycle life.

- Focus on bio-based and recyclable polymer bindersto meet regulatory and sustainability requirements.

- Technological advancements in binder synthesis and processingto optimize performance and reduce manufacturing costs.

Regional Insights

Asia Pacific leads the lithium-ion battery binders market, driven by extensive battery manufacturing capacity, rising EV production, and government incentives for clean energy. Countries such as China, Japan, and South Korea dominate the market, supported by advanced R&D and manufacturing infrastructure. North America is emerging as a high-growth region, with increased investment in domestic battery production, EV adoption, and innovative binder technologies. Europe focuses on sustainable production and high-performance materials for premium EV segments. India is also showing strong growth due to battery localization initiatives and expanding EV manufacturing hubs.

Key Market Drivers

Several factors are driving market expansion:

- Rising global demand for electric vehiclesrequiring high-performance battery systems.

- Growing renewable energy storage applications, including grid-scale storage and residential solutions.

- Advancements in battery chemistrythat require specialized binders for enhanced electrode adhesion and stability.

- Government initiatives promoting EV adoption and clean energy transitions.

- Increasing investments in gigafactory infrastructureto scale battery production efficiently.

Competitive Landscape and Technology Trends

The lithium-ion battery binders market is moderately consolidated, with leading players such as Arkema, BASF SE, LG Chem, DuPont, Solvay, Trinseo, TORAY Industries, DAIKIN Industries, Synthomer PLC, and ZEON Corporation driving innovation. Companies focus on:

- Expanding material portfolios and advanced polymer formulations.

- Developing binders for next-generation battery chemistries, including solid-state batteries.

- Optimizing adhesion and electrochemical stability while maintaining cost efficiency.

- Collaborating with battery cell manufacturers to tailor binders for specific applications.

Technological trends include water-based binders with reduced environmental impact, binders compatible with high-energy-density electrodes, and materials designed to support silicon anodes and solid-state battery integration. These innovations enhance performance, safety, and sustainability in modern lithium-ion batteries.

Challenges

Despite growth opportunities, the market faces challenges:

- Raw material price volatility, impacting manufacturing costs.

- Technical complexity in formulating compatible bindersfor diverse electrode chemistries.

- Intense price competition in battery manufacturinglimiting premium binder adoption.

- Need for advanced R&D capabilitiesto keep pace with evolving battery technologies.

Strategic Implications

For manufacturers: Focus on developing high-performance, sustainable binder formulations compatible with next-generation electrodes. Collaborating with EV and energy storage companies can secure long-term supply contracts and market relevance.

For battery producers: Invest in binder optimization, advanced electrode integration, and performance testing to enhance energy density, cycle life, and battery safety.

For investors: The lithium-ion battery binders market presents strong growth potential fueled by EV proliferation, renewable energy storage expansion, and technological advancements in battery materials. Strategic investment in R&D, production capacity, and sustainable materials can deliver substantial returns.

Outlook Summary

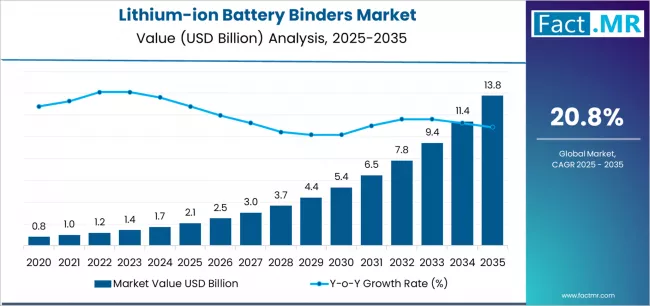

From 2025 to 2035, the lithium-ion battery binders market is poised for robust growth, supported by the expansion of EV production, energy storage systems, and advanced battery technologies. The cathode segment will maintain dominance due to its critical role in high-capacity applications, while anode binders, especially water-based formulations, will continue to grow steadily.

Polyvinylidene fluoride (PVDF) remains the leading material, favored for its reliable electrochemical performance, thermal stability, and adhesion properties. However, emerging eco-friendly polymers and bio-based binders are gaining attention, aligning with global sustainability initiatives.

Asia Pacific will continue to lead the market, with North America and Europe driving innovation and production for premium battery applications. The industry is expected to focus on next-generation technologies, including silicon anodes, high-nickel cathodes, and solid-state batteries, creating opportunities for specialized binder development.

Overall, the lithium-ion battery binders market is integral to the global shift toward electrification and renewable energy storage. Manufacturers, battery producers, and investors positioned to leverage technological advancements, sustainability trends, and rising energy storage demand are poised to benefit from the sector’s sustained growth and strategic importance in powering the future of energy.

Browse Full Report – https://www.factmr.com/report/lithium-ion-battery-binders-market