The engineered spider silk market is entering a defining growth phase as industries worldwide accelerate their transition toward high-performance, lightweight, and environmentally responsible advanced materials. Engineered spider silk, produced through cutting-edge synthetic biology techniques rather than natural harvesting, has emerged as one of the most promising bio-fabricated fibers due to its exceptional tensile strength, elasticity, durability, and biocompatibility. These unique material properties are positioning engineered spider silk as a transformative solution for sectors including medical devices, performance textiles, defense, aerospace, sports equipment, and biotechnology.

Across global manufacturing and R&D landscapes, engineered spider silk is shifting from conceptual research to real-world commercial deployment. Startups, established materials companies, and biotech innovators are scaling production capabilities through genetically engineered bacteria, yeast, and plants, allowing spider silk proteins to be mass-produced without relying on spiders’ natural spinning limitations. This shift from theoretical innovation to industrial-scale manufacturing is reshaping competitive dynamics and opening new revenue streams for players with robust intellectual property, genetic engineering capabilities, and advanced fermentation infrastructure.

Industry Momentum Driven by Rising Need for Sustainable, High-Strength Materials

Market adoption is accelerating due to rising demand for renewable and biodegradable materials that outperform conventional synthetic fibers. As global manufacturers respond to sustainability pressures and environmental regulations, engineered spider silk offers a compelling combination of performance and eco-efficiency. The fiber’s tensile strength rivals high-performing synthetic materials, yet its biodegradability and low ecological footprint position it as a next-generation alternative to petroleum-based fibers used in textiles, composites, and coatings.

In sector after sector, engineered spider silk is gaining traction:

-

In medical applications, the fiber’s biocompatibility, lightweight nature, and strength enable use in sutures, wound dressings, tissue scaffolds, and controlled drug-release systems.

-

In performance and industrial textiles, it enhances durability, stretch resistance, thermal stability, and wearer comfort.

-

Defense organizations are evaluating engineered spider silk for ballistic protection, lightweight armor, resilient fabrics, and next-generation parachute materials.

-

Consumer product brands see potential in footwear, apparel, accessories, and outdoor equipment requiring high-performance, low-impact materials.

These applications are driving consistent investment flows from venture capital firms, strategic corporate partners, and government-backed innovation programs. As a result, the engineered spider silk ecosystem is evolving quickly, with startups competing on both material quality and the scalability of production methods.

To Access the Complete Data Tables & in-depth Insights, Request a Discount on this report: https://www.factmr.com/connectus/sample?flag=S&rep_id=11227

Synthetic Biology Breakthroughs Supporting Commercial Viability

The biggest constraint historically associated with spider silk — the inability to harvest large quantities directly from spiders — has been effectively solved through bioengineering. Using recombinant DNA technology, leading companies have developed microorganisms capable of producing spider silk proteins through fermentation. These proteins are then processed into fibers, films, gels, coatings, or composite materials depending on downstream specifications.

Current R&D efforts focus on:

-

Improving protein expression yields in microbial hosts

-

Enhancing fiber spinning processes to replicate natural silk structures

-

Developing hybrid silk materials with tailored mechanical properties

-

Reducing production costs to enable large-scale commercial competitiveness

-

Enhancing consistency, purity, and material performance during mass production

As breakthroughs continue, engineered spider silk is becoming more predictable, cost-effective, and application-ready. This progress is accelerating partnerships with medical device manufacturers, textile producers, and defense suppliers seeking long-term procurement solutions.

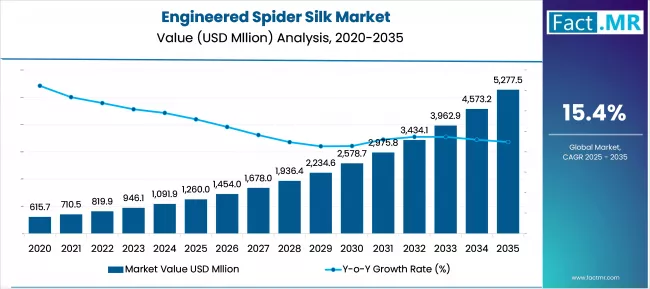

Market Outlook Shows Strong Upside Potential

Industry analysts expect the engineered spider silk market to experience significant growth over the next decade, supported by:

-

Rising corporate investment in sustainable materials

-

Expanding interest from high-value sectors such as aerospace and defense

-

Government grants supporting biomaterial innovation

-

Growing consumer demand for advanced eco-friendly performance products

-

The ability to integrate silk proteins into various forms, including fibers, films, powders, hydrogels, and bio-composites

As the commercial ecosystem matures, engineered spider silk is projected to shift from niche specialty use to broader industrial adoption. Cost-reduction initiatives and higher fermentation capacities are expected to boost availability, making spider silk more competitive with established synthetic performance materials.

Regional Landscape Continues to Evolve

North America and Europe currently lead in research, patent filings, and startup activity. These regions benefit from strong biotechnology infrastructures, well-funded universities, active venture capital participation, and early partnerships between material innovators and end-use industries.

Asia is emerging as a major production hub as biotechnology capabilities expand in countries focused on industrial materials, precision fermentation, and large-scale manufacturing. Growing interest from textile manufacturers, electronics companies, and government-backed research institutions is positioning the region for long-term leadership in volume-based production.

Competitive Landscape and Strategic Priorities

Competition in the engineered spider silk market centers on advances in synthetic biology efficiency and improvements in fiber mechanical properties. Leading companies are prioritizing:

-

New strain development for higher protein yield

-

Process optimization for spinning and fiber alignment

-

Integration of spider silk with other biomaterials or polymers

-

Strategic partnerships with global apparel and medical brands

-

Pilot-scale and commercial-scale production facility expansion

Early movers with strong IP portfolios and advanced fermentation pipelines are expected to capture significant market share as demand grows.

A Transformative Material for the Future

Engineered spider silk stands at the intersection of biotechnology, sustainability, and advanced materials engineering. With unmatched strength-to-weight ratios, low environmental impact, and expanding commercial applications, the material is poised to redefine performance standards across industries. As production scalability improves, engineered spider silk is on track to become one of the most influential biomaterials of the next decade, enabling a wave of innovations in high-performance, sustainable manufacturing.

Have specific requirements or need assistance on report pricing or have a limited budget? Please contact sales@factmr.com

Contact:

US Sales Office

11140 Rockville Pike

Suite 400

Rockville, MD 20852

United States

Tel: +1 (628) 251-1583, +353-1-4434-232

Email: sales@factmr.com

About Fact.MR:

Fact.MR is a global market research and consulting firm, trusted by Fortune 500 companies and emerging businesses for reliable insights and strategic intelligence. With a presence across the U.S., UK, India, and Dubai, we deliver data-driven research and tailored consulting solutions across 30+ industries and 1,000+ markets. Backed by deep expertise and advanced analytics, Fact.MR helps organizations uncover opportunities, reduce risks, and make informed decisions for sustainable growth.