The construction industry is undergoing a technological revolution, and powder-bonding 3D printing has emerged as a transformative solution for building projects. By leveraging additive manufacturing techniques, powder-bonding 3D printing allows for rapid, precise, and sustainable construction, reducing waste and improving efficiency.

This technology uses powdered materials such as cement, concrete, or composite blends, which are selectively bonded layer by layer to create structures ranging from residential homes to complex architectural components. Its integration into construction workflows is redefining traditional building methods, optimizing project timelines, and enabling designs that were previously difficult or impossible to achieve.

Market Overview

The powder-bonding 3D printing construction market covers a spectrum of equipment, materials, and software solutions designed for additive manufacturing in the construction sector. This technology reduces reliance on conventional formwork and labor-intensive processes, offering faster, cost-efficient, and customizable solutions.

Advanced powder-bonding printers can produce walls, structural elements, facades, and intricate architectural designs with high precision. Additionally, the use of pre-mixed or tailored powders allows for enhanced material properties, including strength, durability, and environmental resistance. As a result, builders can construct robust structures while maintaining flexibility in design, material use, and architectural complexity.

Sustainability is a key driver, as powder-bonding 3D printing minimizes construction waste and promotes energy-efficient building practices. Combined with modular and prefabricated approaches, this technology is set to revolutionize construction practices globally.

Regional Insights

The adoption of powder-bonding 3D printing varies across regions based on infrastructure growth, construction activity, and technology readiness:

- North America is a frontrunner in embracing 3D printing technologies for construction, supported by research institutions, innovative startups, and government-backed pilot projects. Large-scale commercial and residential projects are increasingly integrating powder-bonding techniques for efficient construction.

- Europe demonstrates strong adoption due to regulatory incentives for sustainable construction, advanced R&D capabilities, and a focus on architectural innovation. Countries like Germany, the Netherlands, and France are leading in experimental and commercial 3D-printed structures.

- Asia Pacific is emerging as a rapidly expanding market, fueled by urbanization, infrastructure development, and smart city initiatives in China, Japan, and India. Governments and developers are exploring additive manufacturing to meet housing demands, reduce construction timelines, and improve cost efficiency.

- Middle East & Africa are witnessing interest in luxury, commercial, and industrial construction, where powder-bonding 3D printing provides opportunities for rapid prototyping, sustainable building practices, and unique architectural designs.

Regional adoption reflects both the maturity of the construction industry and the strategic focus on innovation and sustainability in building practices.

Key Trends & Forecast

The powder-bonding 3D printing construction market is evolving under several transformative trends:

- Sustainability and Waste Reduction: Additive manufacturing reduces material waste and energy use, aligning with global sustainability and green building initiatives.

- Automation and Digital Integration: Integration with Building Information Modeling (BIM) and other digital design tools enhances precision, reduces errors, and optimizes construction workflows.

- Customization and Complex Design: Powder-bonding 3D printing allows for highly customized architectural elements, facades, and interior structures, providing design flexibility that traditional construction methods cannot match.

- Rapid Construction Timelines: Automated layer-by-layer printing significantly shortens construction schedules, enabling developers to meet deadlines and reduce labor costs.

- Material Innovation: Advancements in cementitious powders, polymer composites, and hybrid materials are improving strength, durability, and functional properties of printed structures.

These trends suggest a market moving toward more efficient, sustainable, and versatile construction methods, addressing both industrial and environmental requirements.

Applications & End-Use Outlook

Powder-bonding 3D printing has a broad range of applications across residential, commercial, and industrial construction:

- Residential Construction: Single-family homes, multi-story buildings, and modular housing units can be printed efficiently with reduced labor and material costs.

- Commercial and Industrial Projects: Office complexes, hotels, and industrial facilities utilize powder-bonding techniques for complex layouts, structural efficiency, and rapid construction timelines.

- Architectural Elements: Intricate facades, decorative walls, and structural components benefit from high-precision additive manufacturing, enabling unique designs and creative freedom.

- Infrastructure and Public Projects: Bridges, pedestrian walkways, and utility structures are increasingly incorporating powder-bonding 3D printing for rapid deployment and cost efficiency.

- Disaster Relief and Temporary Structures: Rapidly deployable shelters and temporary facilities can be produced using modular powder-bonding 3D printed components, supporting emergency and humanitarian applications.

The versatility and adaptability of powder-bonding 3D printing position it as a disruptive solution across multiple construction sectors.

Competitive Landscape

The powder-bonding 3D printing construction market is highly dynamic, with global manufacturers, startups, and research organizations driving innovation. Companies are focusing on advanced printer technology, material development, and software integration to improve accuracy, speed, and cost-effectiveness.

Collaborations with construction firms, real estate developers, and research institutions are enabling customized solutions for specific project needs. Additionally, service-oriented offerings such as on-site 3D printing support, training, and consulting are emerging as differentiators in a competitive landscape.

As the market matures, players prioritizing technology innovation, sustainability, and operational efficiency are expected to lead adoption across residential, commercial, and infrastructure applications.

Conclusion

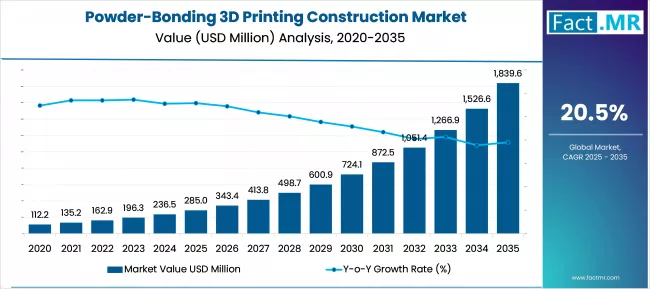

The powder-bonding 3D printing construction market is poised for rapid growth as the construction industry increasingly embraces additive manufacturing for efficiency, sustainability, and design innovation. By combining precision, speed, and material efficiency, powder-bonding 3D printing is transforming traditional construction practices.

As urbanization accelerates and the demand for innovative, cost-effective, and environmentally friendly building solutions rises, this technology will play a critical role in shaping the future of construction. Powder-bonding 3D printing is not just a technological advancement—it is a pathway to smarter, faster, and more sustainable building practices worldwide.

With continued material innovation, digital integration, and global adoption, powder-bonding 3D printing is set to redefine construction norms, enabling developers, architects, and engineers to create structures that are both functional and visually remarkable.

Browse Full Report – https://www.factmr.com/report/powder-bonding-3d-printing-construction-market