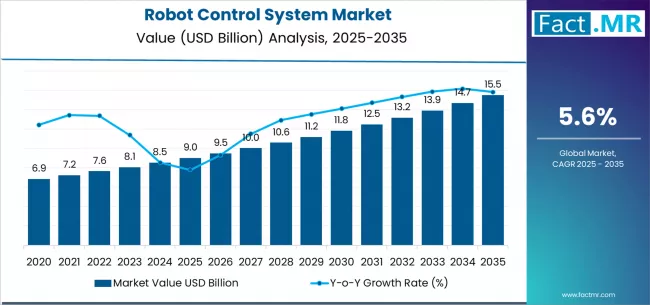

The global robot control system market is on a robust growth trajectory, reflecting the rapid integration of intelligent automation across manufacturing, logistics, and electronics industries. According to a recent report by Fact.MR, the market is projected to expand from USD 9.0 billion in 2025 to USD 15.8 billion by 2035, registering a CAGR of 5.6% during the forecast period.

This steady rise underscores the growing adoption of advanced automation control technologies, AI-based motion systems, and industrial robotics aimed at improving precision, productivity, and operational resilience in high-demand sectors.

Strategic Market Drivers

Industrial Automation and Smart Manufacturing Revolution

The accelerating shift toward Industry 4.0 is the cornerstone of growth for the robot control system market. Manufacturers are increasingly deploying robotic control systems for welding, assembly, inspection, and packaging tasks to minimize human error and enhance process efficiency.

Smart factories integrating IoT-connected robotic systems and real-time data analytics are driving demand for adaptive and scalable control platforms capable of seamless coordination among multi-axis robots and automated lines.

Automotive Sector: The Core of Robotic Adoption

Automotive manufacturers continue to lead global investment in robotic control systems, leveraging them for body assembly, material handling, painting, and precision machining.

With the shift toward electric vehicles (EVs), automation demand is intensifying to manage new assembly requirements for batteries and power electronics. Control systems featuring AI-assisted motion control, force feedback technology, and predictive maintenance capabilities are becoming vital to sustain quality and production throughput.

Electronics and Semiconductor Expansion

The growing complexity of semiconductor fabrication and electronic component assembly has spurred demand for high-speed, ultra-precise robotic control systems.

Manufacturers are turning to AI-integrated controllers for microchip placement, wafer inspection, and surface-mount assembly to ensure consistency at nanometer precision. This trend, coupled with the miniaturization of consumer devices, is opening new frontiers for control system developers.

Logistics, Healthcare, and Service Robotics on the Rise

Beyond manufacturing, industries such as logistics, healthcare, and retail are embracing robotic automation for picking, sorting, and delivery tasks.

Autonomous mobile robots (AMRs) and collaborative robots (cobots) require advanced control algorithms to enable safe human-machine interaction, obstacle avoidance, and adaptive navigation—further propelling innovation in robot control architecture.

Browse Full Report: https://www.factmr.com/report/robot-control-system-market

Regional Growth Highlights

East Asia: The Global Automation Hub

East Asia remains the largest and fastest-growing market for robot control systems. China, Japan, and South Korea are leading in industrial robot installations, supported by strong manufacturing output and pro-automation government initiatives.

China’s “Made in China 2025” policy, coupled with Japan’s robotics excellence, continues to drive investment in next-generation robotic controllers that emphasize AI-driven performance optimization and digital twin simulations.

North America: Innovation and AI Integration

In North America, the United States is at the forefront of integrating robotics with artificial intelligence, cloud computing, and cybersecurity.

Manufacturers are prioritizing edge computing-based control systems to enhance responsiveness and safety. The region’s logistics and e-commerce sectors are also fueling adoption of intelligent robot control units for automated warehousing and delivery solutions.

Europe: Emphasis on Safety, Compliance, and Sustainability

Europe’s automation growth is shaped by stringent safety standards, energy efficiency goals, and sustainability mandates.

Countries like Germany, Italy, and France are leading adopters of modular and eco-efficient control platforms, especially in automotive and packaging sectors. EU-funded initiatives promoting AI-enabled robotics are expected to bolster long-term adoption.

Emerging Markets: Industrialization and Workforce Optimization

Regions such as South Asia, the Middle East, and Latin America are witnessing increased automation investment to boost manufacturing productivity and reduce labor dependency.

Rapid industrialization, coupled with a growing emphasis on technological upskilling, is positioning these regions as new growth hubs for robot control solutions.

Market Segmentation Insights

By Type

- Motion Control Systems – Core to precision automation and industrial robotics.

- PLC-Based Control Systems – Essential for large-scale manufacturing operations.

- CNC Control Systems – Widely used in machining, metalworking, and fabrication sectors.

- Distributed Control Systems (DCS) – Growing adoption in process and energy industries.

By End Use

- Automotive & Transportation

- Electronics & Semiconductors

- Industrial Manufacturing

- Logistics & Warehousing

- Healthcare & Service Robotics

Challenges and Market Considerations

Despite strong potential, the robot control system market faces several challenges:

- High Initial Investment: Advanced control systems require significant capital expenditure.

- Cybersecurity Risks: Increased connectivity exposes systems to data and operational threats.

- Skill Shortage: Shortfall of robotics engineers and AI programmers hampers full-scale adoption.

- Integration Complexity: Diverse robotic ecosystems demand interoperability and software standardization.

Competitive Landscape

The global robot control system market is marked by rapid technological evolution and strategic collaboration between hardware and software innovators.

Leading companies are investing in AI-powered control platforms, edge computing, and cloud robotics integration to offer flexible, efficient, and secure automation solutions.

Key Players in the Robot Control System Market

- Rockwell Automation

- Siemens

- ABB

- Mitsubishi Electric

- Fanuc

- Omron

- Schneider Electric

- KUKA

- Yaskawa

- Beckhoff Automation

Future Outlook: Toward Autonomous and Adaptive Robotics

The next decade will redefine industrial automation, with robot control systems evolving into self-learning, adaptive, and energy-efficient intelligence platforms.

As artificial intelligence, sensor fusion, and digital twin technologies mature, robot controllers will become central to autonomous decision-making, predictive operations, and zero-defect manufacturing.

With solid growth across automotive, electronics, and logistics sectors, the global robot control system market is poised to become a foundation of the intelligent industry era—driving the transition toward smarter, safer, and more sustainable automation ecosystems.