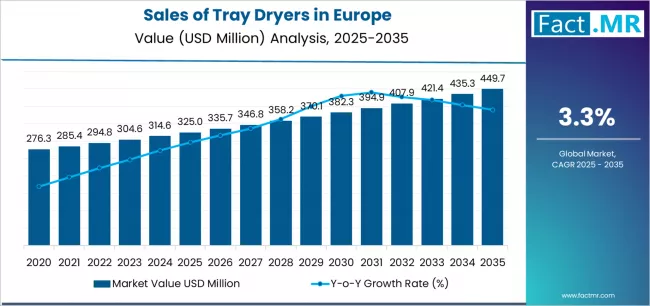

The Europe tray dryers market is poised for steady expansion, supported by strong demand across pharmaceutical, food processing, and chemical manufacturing industries. According to a recent report by Fact.MR, the regional market is forecast to grow from USD 325.0 million in 2025 to approximately USD 451.0 million by 2035, recording an absolute increase of USD 126.0 million over the period. This reflects total growth of 38.8%, with demand projected to expand at a CAGR of 3.3% between 2025 and 2035.

Tray dryers are essential components of controlled drying systems, widely used to remove moisture from heat-sensitive materials under uniform temperature conditions. Their ability to ensure consistent product quality, energy efficiency, and precise temperature control has made them indispensable in regulated industrial processes across Europe.

Key Market Drivers:

- Expanding Pharmaceutical and Biotechnology Production

The pharmaceutical sector continues to dominate tray dryer consumption in Europe. The region’s expanding drug manufacturing base, coupled with increasing investments in vaccine, biologics, and API production, is driving robust demand. Tray dryers play a crucial role in ensuring consistent drying of granules, powders, and formulations under GMP-compliant conditions.

Moreover, the integration of automated drying systems equipped with advanced control interfaces is enabling higher productivity and lower contamination risks.

- Food Processing Industry’s Shift Toward Quality Preservation

The food processing industry in Europe is adopting modern tray dryers to meet the growing need for nutrient preservation and shelf-life extension in processed foods. Demand for clean-label, dehydrated, and natural food ingredients has increased significantly, encouraging manufacturers to adopt energy-efficient and hygienic drying systems.

Countries such as Germany, France, and Italy are leading in food technology innovations that integrate precision drying for herbs, fruits, and nutraceuticals.

- Sustainable and Energy-Efficient Manufacturing

Environmental sustainability remains a defining factor shaping industrial equipment demand across Europe. Tray dryer manufacturers are responding with energy-optimized designs, low-emission heating systems, and improved insulation technologies. These solutions not only reduce operational costs but also align with the European Union’s Green Deal targets focused on energy conservation and carbon neutrality.

- Rising Adoption in Specialty Chemical and Material Processing

The specialty chemical industry in Europe, particularly in Germany and Switzerland, is witnessing increasing use of tray dryers for moisture-sensitive powders, pigments, and catalysts. The precise temperature control and scalability of these systems make them ideal for laboratory-scale and bulk drying applications. Additionally, the electronics and materials industries are leveraging tray dryers for controlled heat treatment of polymers and composites.

Browse Full Report: https://www.factmr.com/report/sales-of-tray-dryers-in-europe

Regional Growth Insights:

Western Europe: Technological Leadership

Western Europe remains the hub of advanced drying technology, with Germany, the U.K., and France leading in innovation and equipment modernization. Strong pharmaceutical manufacturing capabilities and a focus on high-quality standards continue to drive regional dominance.

Manufacturers in this region are adopting digitalized monitoring systems and IoT-integrated controls to enhance operational visibility and predictive maintenance.

Eastern Europe: Emerging Manufacturing Base

Eastern European countries, including Poland, Hungary, and the Czech Republic, are emerging as cost-competitive hubs for pharmaceutical and chemical manufacturing. Supported by foreign direct investments and favorable regulatory frameworks, these regions are witnessing an increased installation of industrial drying systems for both domestic and export-oriented production.

Market Segmentation Insights

By Type:

- Electric Tray Dryers: Gaining prominence in small- to medium-scale operations for their precise heat control and ease of use.

- Steam Tray Dryers: Widely adopted in large-scale food and pharmaceutical processing for efficient bulk drying.

- Infrared and Hybrid Tray Dryers: Emerging as next-generation solutions combining rapid drying with energy efficiency.

By End-Use Industry:

- Pharmaceutical & Biotechnology – Largest segment driven by stringent regulatory compliance and consistent process validation needs.

- Food & Beverage – Rising adoption for dehydrating natural food products and enhancing storage stability.

- Chemical & Material Processing – Growing application in specialty chemicals and polymer production.

- Research Laboratories & Academic Institutions – Increasing use in small-batch and experimental drying applications.

Key Challenges:

- High Initial Capital Investment: Advanced automation and temperature control features can increase upfront costs.

- Maintenance and Operational Efficiency: Regular calibration and uniform airflow management remain essential for quality assurance.

- Competition from Alternative Drying Technologies: Freeze and spray drying methods pose performance and efficiency challenges in specific applications.

Competitive Landscape:

The Europe tray dryers market is characterized by the presence of established manufacturers and technology-driven SMEs focusing on customization, energy optimization, and automation.

Key Players in Europe Tray Dryers include:

- MV International

- Powder Systems Limited

- Pharma Fab Industries

- Standard Group of Companies Ltd

- Shree Bhagwati India Pvt Ltd

- Anutec International

- L.B. Bohle Maschinen

- GEA Group AG

- Bühler AG

These companies are investing in product differentiation through advanced heat distribution systems, modular designs, and IoT-based process control technologies to enhance operational efficiency and traceability.

Future Outlook: Toward Smart and Sustainable Drying Systems

The future of the European tray dryers market lies in smart manufacturing, sustainability, and regulatory alignment. Manufacturers are incorporating AI-driven performance analytics, automated cycle optimization, and eco-friendly materials to improve energy use and process reliability.

As industries continue to prioritize product quality, safety, and energy efficiency, tray dryers will remain central to Europe’s evolving industrial processing landscape — delivering precision, performance, and sustainability for the next generation of manufacturing.