The intralogistics market is experiencing rapid transformation as businesses worldwide embrace automation, digitalization, and intelligent material handling to meet evolving supply chain demands. Intralogistics — which encompasses the organization, movement, and optimization of goods within warehouses, manufacturing facilities, and distribution centers — has become a strategic pillar for operational excellence.

Driven by e-commerce growth, labor shortages, and the rising need for efficiency, companies are adopting intralogistics solutions such as automated guided vehicles (AGVs), robotic picking systems, conveyor networks, and warehouse management software. The market’s expansion reflects a shift toward smart, interconnected facilities that combine physical and digital systems to enhance productivity, traceability, and sustainability.

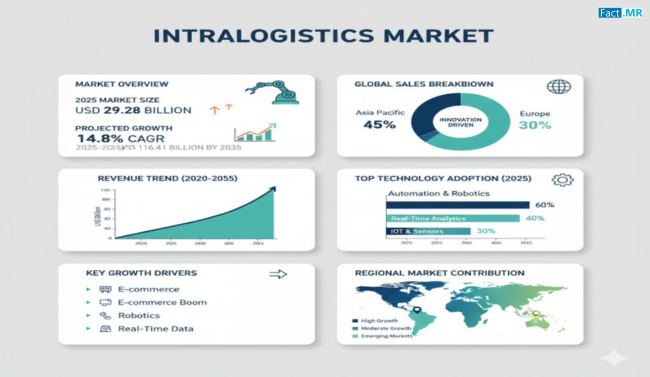

Market Overview

Intralogistics integrates a range of technologies and processes designed to streamline the internal flow of materials and information. It encompasses activities such as storage, inventory management, order fulfillment, and material transportation — all optimized through automation and digital control systems.

The growing complexity of global supply chains has elevated the importance of intralogistics systems as a core enabler of resilience and competitiveness. Companies across industries are investing in intelligent warehouse infrastructure to minimize operational downtime, reduce manual intervention, and improve throughput.

Technological innovations — from robotics and AI to Internet of Things (IoT)-enabled sensors — are revolutionizing warehouse operations. Modern intralogistics solutions enable real-time visibility of goods, predictive maintenance, and data-driven decision-making. Sustainability is another driving factor, as energy-efficient automation and space optimization help companies reduce waste and carbon emissions.

Manufacturers, logistics providers, and retailers are increasingly recognizing intralogistics as a vital component of end-to-end supply chain optimization. The focus is now on creating agile systems that can adapt to fluctuating market demands while maintaining high levels of accuracy and efficiency.

Regional Insights

Europe is a frontrunner in intralogistics innovation, supported by strong adoption of Industry 4.0 principles and widespread automation in manufacturing and warehousing sectors. European companies are integrating advanced robotics, automated storage and retrieval systems (AS/RS), and AI-driven software to enhance operational flexibility and efficiency.

North America is another key market, characterized by a high concentration of e-commerce fulfillment centers and logistics service providers. The region’s growing reliance on robotics and cloud-based warehouse management solutions is redefining distribution operations. Labor shortages in warehouse operations have further accelerated the demand for automation and digital process control.

Asia-Pacific is witnessing robust growth driven by rapid industrialization, urbanization, and the expansion of manufacturing and retail sectors. Countries such as China, Japan, India, and South Korea are heavily investing in automation technologies to enhance supply chain efficiency. The region’s booming e-commerce sector is also propelling demand for scalable intralogistics solutions.

In Latin America and the Middle East & Africa, modernization of logistics infrastructure and the growing presence of international trade are fueling market opportunities. Governments and private enterprises are focusing on upgrading warehouse systems to support efficient cross-border logistics and meet the needs of expanding consumer markets.

Key Trends & Forecast

- Automation and Robotics Integration:

The deployment of autonomous mobile robots (AMRs), AGVs, and collaborative robots is transforming warehouse efficiency. These technologies enable faster, safer, and more accurate handling of goods. - Adoption of Artificial Intelligence and Machine Learning:

AI is increasingly being used to predict demand, optimize inventory, and enhance order accuracy. Machine learning algorithms analyze historical and real-time data to streamline operations and minimize errors. - Growth of E-Commerce and Omnichannel Retail:

The surge in online shopping has intensified pressure on warehouses to manage diverse product ranges and shorter delivery times. Intralogistics systems are being upgraded to handle high-speed order processing and last-mile coordination. - Sustainability and Energy Efficiency:

Green intralogistics solutions — such as energy-saving conveyors, recyclable materials, and solar-powered systems — are gaining traction as companies aim to reduce their environmental footprint. - Integration of Digital Twins and IoT:

Digital twin technology allows businesses to simulate warehouse environments for performance optimization, while IoT sensors enhance visibility, track asset conditions, and support predictive maintenance. - Collaborative Ecosystems:

Partnerships between technology developers, logistics providers, and software companies are fostering innovation in integrated intralogistics platforms that combine automation hardware with cloud-based analytics.

These trends collectively underscore the shift toward a data-driven, intelligent, and sustainable intralogistics ecosystem designed for resilience and scalability.

Applications & End-Use Outlook

Intralogistics solutions are vital across multiple sectors, including manufacturing, e-commerce, retail, automotive, pharmaceuticals, and food & beverage industries.

In the manufacturing sector, intralogistics systems play a key role in optimizing the movement of raw materials, semi-finished goods, and components across production lines. Automated conveyors, robotic arms, and storage systems enhance process flow and reduce lead times.

The e-commerce and retail industries represent one of the fastest-growing segments, where intralogistics ensures quick order fulfillment, efficient inventory management, and seamless returns processing. Automated warehouses and robotic picking systems are becoming essential to meet consumer expectations for rapid delivery.

In automotive and industrial operations, intralogistics supports just-in-time manufacturing models by synchronizing material flow with assembly schedules. The deployment of AGVs and autonomous forklifts improves safety and precision in component delivery.

Pharmaceutical and food & beverage sectors are adopting intralogistics systems to maintain strict hygiene, temperature control, and traceability standards. Automation reduces the risk of contamination and enhances compliance with regulatory requirements.

As businesses expand globally and customer expectations evolve, intralogistics is transitioning from a supportive function to a strategic differentiator that enhances agility, efficiency, and profitability.

Conclusion

The intralogistics market is reshaping how businesses manage internal logistics operations, ushering in an era of automation, intelligence, and sustainability. From robotic warehouses to data-driven decision-making, the future of intralogistics is centered on creating efficient, resilient, and environmentally responsible supply chains.

Manufacturers and logistics providers are leveraging technology to overcome operational challenges, improve productivity, and meet growing customer demands for speed and accuracy. As global industries continue to digitalize, intralogistics will remain at the core of innovation — driving seamless coordination between people, machines, and data.

Access to in-depth market insights can help organizations identify opportunities, adopt cutting-edge technologies, and position themselves at the forefront of supply chain modernization. Intralogistics is not just about moving goods — it’s about moving industries toward a smarter, more sustainable future.

Browse Full Report – https://www.factmr.com/report/3446/intralogistics-market