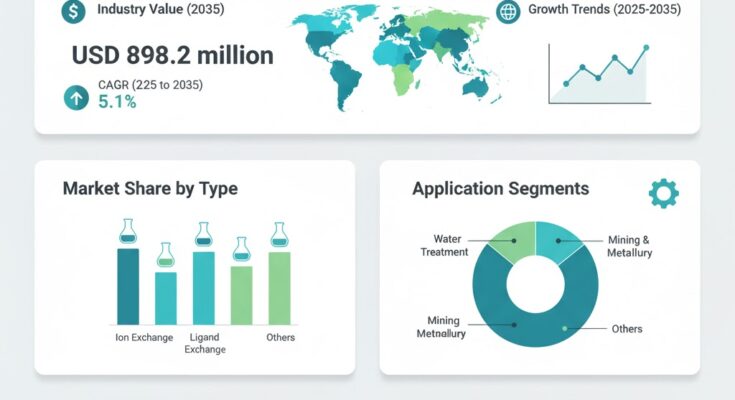

The global chelating resins market is poised for significant expansion as industries worldwide intensify their focus on water purification, resource recovery, and sustainable chemical processes. According to a recent report by Fact.MR, the market is expected to grow from USD 519.7 million in 2024 to USD 898.2 million by 2035, reflecting a CAGR of 5.1% during the forecast period (2025–2035).

Chelating resins specialized ion exchange resins designed to selectively bind metal ions—are gaining prominence across industrial, municipal, and environmental sectors for their role in removing heavy metals, purifying process streams, and enabling efficient resource recovery.

Strategic Market Drivers:

- Rising Demand from Industrial Water Treatment Applications

Industrial wastewater management remains the largest end-use segment for chelating resins. Rapid industrialization and stricter discharge regulations are compelling manufacturers to adopt advanced purification technologies. Chelating resins are particularly effective in removing trace heavy metals such as lead, copper, zinc, and nickel—making them indispensable in electroplating, mining, and power generation industries.

Furthermore, government initiatives to promote circular water use and reduce industrial effluents are driving broader adoption of ion exchange technologies globally.

- Expanding Role in Hydrometallurgy and Resource Recovery

Chelating resins are increasingly used in hydrometallurgical operations to recover valuable metals like cobalt, lithium, and rare earth elements. As demand for electric vehicle batteries and renewable energy components surges, manufacturers are turning to selective resin-based extraction systems that offer high purity, recyclability, and operational efficiency. This trend is especially prominent in East Asia and North America, where battery material supply chains are expanding rapidly.

- Growing Environmental and Municipal Applications

Chelating resins are finding new applications in environmental remediation—particularly in the removal of toxic metals from soil and groundwater. Their capacity to operate in variable pH conditions and maintain high selectivity even in complex matrices makes them ideal for ecological clean-up operations and municipal water purification projects.

- Rising Adoption in Pharmaceuticals and Food Processing

The pharmaceutical and food industries are also leveraging chelating resins for high-purity separations, enzyme immobilization, and trace metal removal in manufacturing processes. Increasing quality and safety standards, coupled with demand for contamination-free production systems, are reinforcing the material’s market penetration across these sectors.

Regional Growth Highlights

East Asia: The Global Manufacturing and Processing Hub

East Asia remains the largest regional market, with China, Japan, and South Korea at the forefront of resin production and application. Strong manufacturing bases in chemicals, electronics, and metallurgy, combined with rapid industrial wastewater treatment projects, underpin regional growth. Moreover, the expansion of the lithium-ion battery and semiconductor industries further amplifies demand for selective metal recovery resins.

North America: Sustainability and Technological Innovation

North America is witnessing steady market expansion driven by technological advancements and stringent environmental norms. The U.S. and Canada are emphasizing sustainable water management systems, where chelating resins are vital in closed-loop and zero-liquid discharge (ZLD) systems. Ongoing R&D investments in green chemistry and next-generation resin technologies are enhancing local competitiveness.

Europe: Regulation-Driven Growth and Resource Recovery

Europe’s commitment to the EU Water Framework Directive and circular economy goals continues to bolster the adoption of chelating resins. Germany, France, and the U.K. are leading the integration of high-performance resins into industrial wastewater treatment, rare metal recovery, and chemical manufacturing applications.

Regional producers are focusing on developing bio-based and low-toxicity resins to meet stringent environmental standards.

Emerging Markets: Rapid Urbanization and Industrialization

South Asia, Latin America, and the Middle East are emerging as high-potential growth regions, propelled by accelerating urban infrastructure development and industrial expansion. Countries such as India, Brazil, and Saudi Arabia are investing heavily in wastewater recycling and desalination projects, creating favorable conditions for chelating resin adoption.

Market Segmentation Insights

By Type

- Iminodiacetate Resins – Widely used for general heavy metal removal and hydrometallurgy applications.

- Aminophosphonic Resins – Preferred for high selectivity toward alkaline earth and transition metals.

- Ethylenediamine and Other Functional Resins – Applied in niche separations requiring strong binding strength and high purity.

By End Use Industry

- Water & Wastewater Treatment – Dominant segment driven by industrial effluent and municipal purification needs.

- Mining & Metallurgy – Expanding usage in selective metal extraction and recovery.

- Chemical & Petrochemical – Applied in catalyst purification and process water conditioning.

- Food & Pharmaceutical Processing – Increasing use in high-purity production systems.

Challenges and Market Considerations

Despite strong growth prospects, the chelating resins market faces several structural challenges:

- High Raw Material Costs – Price fluctuations of polymer and monomer feedstocks impact production economics.

- Regulatory Complexity – Environmental restrictions on resin disposal and regeneration chemicals add compliance costs.

- Technical Limitations – Reduced efficiency in highly fouled or complex water matrices may necessitate multi-step treatment systems.

- Competition from Alternative Technologies – Emerging nanofiltration and biosorption technologies are creating competitive pressure in specific applications.

Competitive Analysis

The chelating resins market is moderately consolidated, with global and regional players emphasizing technological innovation, product diversification, and sustainability.

Key companies operating in the market include:

- LANXESS

- Mitsubishi Chemical Corporation

- Purolite

- DuPont

- Sunresin New Materials Co. Ltd.

- Ion Exchange (India) Limited

- Thermax Limited

- Suqing Group

- Samyang Corporation

- ResinTech

- SH Scenic Resin Co. Ltd.

- Jiangsu Widevision Environmental Protection Technology Co., Ltd.

- Jacobi

- BleachCo. Ltd.

These companies are focusing on expanding production capacities, strengthening global distribution networks, and developing highly selective, regeneration-efficient resins tailored for next-generation environmental and industrial applications.

Recent Developments

- September 2023 – DuPont launched its first resin designed for green hydrogen production, DuPont™ AmberLite™ P2X110 Ion Exchange Resin, enabling efficient ion exchange and durability in electrolyzer systems.

- October 2023 – LANXESS expanded its Lewatit MonoPlus TP 109 line, introducing a macroporous anion exchange resin specifically engineered to remove per- and polyfluoroalkyl substances (PFAS) from contaminated water.

Future Outlook: Toward Circular and Sustainable Resin Technologies

The global chelating resins market is set to undergo a major transformation as industries move toward sustainable water and material management. Advancements in resin chemistry, AI-assisted process monitoring, and renewable polymer sourcing will define the next phase of innovation.

With mounting environmental pressures, regulatory support, and industrial modernization, the market is on track for resilient growth. Companies that invest in eco-efficient production, advanced selectivity designs, and circular recovery models will be best positioned to lead in the evolving landscape of global water and chemical sustainability.