Steel tubes form the backbone of numerous industries—from construction and automotive to oil & gas and mechanical engineering. Known for their durability, strength, and versatility, steel tubes are critical in structural frameworks, fluid transportation, and industrial applications. As global infrastructure development and industrial modernization continue to accelerate, the steel tubes market is evolving with innovations in materials, manufacturing processes, and sustainable production practices.

Market Overview

The steel tubes market comprises seamless and welded tubes used across diverse industrial applications. These tubes are favored for their superior mechanical properties, resistance to corrosion, and ability to withstand high pressure and temperature. With increasing emphasis on long-lasting, eco-efficient infrastructure, steel tubes are emerging as indispensable components in pipelines, automotive systems, and construction frameworks.

Ongoing advancements in metallurgy and manufacturing technologies—such as hot rolling, cold drawing, and laser welding—are improving product quality and performance. Moreover, the integration of automation and digital quality control in steel tube production is enhancing precision, reducing material waste, and optimizing production efficiency.

Sustainability has become a defining trend, with manufacturers adopting circular economy practices. Recycling initiatives and energy-efficient production methods are reshaping the industry, aligning it with global environmental goals while maintaining product strength and reliability.

Regional Insights

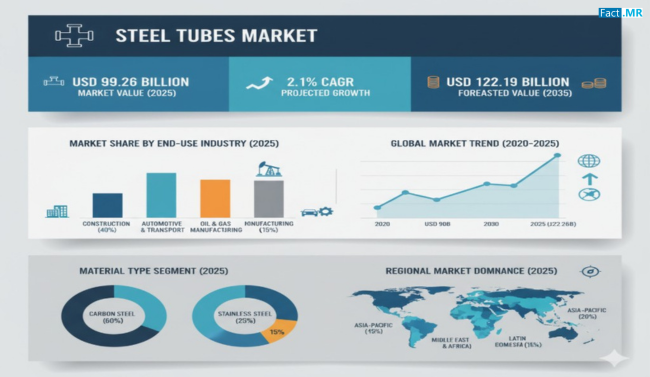

Asia Pacific dominates the global steel tubes market due to rapid industrialization, robust construction growth, and expanding energy infrastructure. Countries like China, India, and Japan are major consumers and producers, driven by infrastructure projects, pipeline expansions, and automotive manufacturing.

North America continues to invest heavily in energy exploration, shale gas production, and pipeline networks, fueling demand for high-performance steel tubes. The region’s emphasis on advanced manufacturing and modernization of transportation systems further supports market expansion.

Europe is focusing on sustainable steel production and industrial decarbonization. The region’s stringent environmental standards and push toward renewable energy infrastructure—such as wind and solar—are creating demand for specialized steel tubes designed for energy-efficient systems.

Latin America and the Middle East & Africa are emerging as promising markets, driven by ongoing oil & gas exploration, construction projects, and growing urban infrastructure. Increasing government investments in industrial development and housing are also contributing to regional market growth.

Key Trends & Forecast

The steel tubes market is witnessing dynamic shifts driven by technological innovation, sustainability goals, and industrial diversification. Key trends shaping the future include:

- Rise of High-Strength and Lightweight Steel Tubes:

Manufacturers are developing advanced alloys and high-tensile steel tubes that combine strength with reduced weight, supporting efficiency in automotive and construction applications. - Digitalization and Smart Manufacturing:

The adoption of automation, robotics, and data analytics in production facilities is enhancing product precision, consistency, and traceability while reducing operational costs. - Sustainable Steel Production:

Eco-friendly production techniques, including the use of electric arc furnaces and recycled scrap metal, are reducing carbon emissions and energy consumption. This shift aligns with global green manufacturing initiatives. - Growth in Energy Infrastructure:

Expansion of oil & gas pipelines, renewable energy systems, and industrial utilities is boosting demand for durable, corrosion-resistant steel tubes that can handle high pressure and temperature. - Expansion in Construction and Urban Development:

The global push for urbanization, smart city projects, and infrastructure modernization continues to fuel demand for structural steel tubes in high-rise buildings, bridges, and transportation networks. - Increased Demand in Automotive Manufacturing:

Lightweight yet strong steel tubes are increasingly used in vehicle chassis, exhaust systems, and safety components to enhance fuel efficiency and structural integrity. - Innovation in Coatings and Surface Treatments:

To improve corrosion resistance and extend service life, manufacturers are incorporating advanced surface coatings such as galvanization, epoxy, and polymer-based treatments. - Focus on Customization and Precision Engineering:

End-users are seeking application-specific solutions. Customized tube sizes, grades, and finishes are becoming essential in sectors like aerospace, chemical processing, and heavy machinery.

Applications & End-Use Outlook

Steel tubes serve as foundational components across a range of industries, delivering mechanical strength, adaptability, and reliability:

- Construction and Infrastructure:

Structural steel tubes are essential in the development of buildings, bridges, and transportation systems. Their ability to bear heavy loads and resist deformation makes them indispensable for modern architecture. - Oil & Gas Industry:

Steel tubes are widely used for exploration, drilling, and transportation of oil, gas, and petrochemical products. Seamless tubes, in particular, offer high resistance to pressure and corrosion in extreme environments. - Automotive and Transportation:

The automotive sector utilizes steel tubes in exhaust systems, axles, and frameworks. The increasing focus on fuel-efficient and lightweight vehicles is driving demand for high-strength tubular components. - Energy and Power Generation:

In power plants and renewable energy projects, steel tubes are used for heat exchangers, boilers, and wind turbine structures, supporting energy transmission and efficiency. - Mechanical and Industrial Engineering:

Steel tubes play a crucial role in machinery manufacturing, hydraulic systems, and process industries. Their precision and versatility make them ideal for equipment that requires durability and high performance. - Water and Wastewater Management:

Infrastructure projects related to water distribution and sewage systems rely on steel tubes for their strength, longevity, and resistance to internal and external corrosion.

Competitive Landscape

The steel tubes market features a blend of global manufacturers and regional suppliers competing through innovation, quality, and sustainability. Leading players are expanding their production capacities, optimizing supply chains, and adopting advanced manufacturing technologies to meet rising demand.

Strategic alliances, mergers, and acquisitions are common as companies aim to strengthen their global footprint and diversify their product portfolios. Investments in R&D are driving the creation of advanced steel grades, automated fabrication systems, and enhanced corrosion-resistant solutions.

Moreover, companies are increasingly focusing on value-added services such as on-site installation support, material testing, and lifecycle monitoring to enhance customer satisfaction and build long-term relationships.

Future Outlook

The future of the steel tubes market lies in balancing industrial growth with environmental responsibility. As infrastructure expansion, renewable energy projects, and automotive innovation accelerate, steel tubes will remain central to modern engineering and construction.

Emerging trends such as green steel production, automation, and digital monitoring are set to redefine the industry’s landscape. The integration of AI and IoT into manufacturing will enable predictive maintenance and improved quality assurance, ensuring operational excellence.

Furthermore, growing investments in hydrogen energy, carbon capture systems, and smart cities are expected to open new avenues for steel tube applications, reinforcing their role in sustainable industrial development.

Conclusion

The steel tubes market stands as a pillar of strength for global infrastructure and industry. Its evolution reflects the world’s broader shift toward sustainable growth, technological innovation, and efficient resource utilization. As industries continue to modernize, the demand for durable, versatile, and eco-conscious steel tubes will only intensify. By embracing cleaner production methods and digital transformation, the steel tubes industry is well-positioned to drive the next era of industrial and infrastructural excellence.

Browse Full Report – https://www.factmr.com/report/480/steel-tubes-market