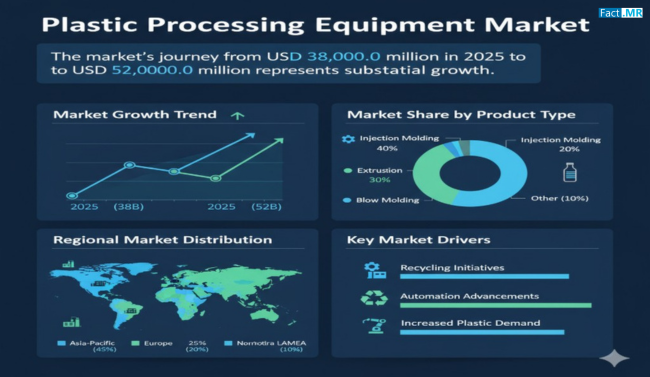

Plastic processing equipment plays a pivotal role in transforming raw plastics into functional, high-quality products for diverse industries. As manufacturing demands increase, the market for plastic processing equipment is experiencing steady growth, driven by technological innovations and widespread adoption across sectors such as packaging, automotive, electronics, and healthcare. These machines enable efficient production, precision molding, and cost-effective solutions, positioning them as essential tools in modern manufacturing.

Market Overview:

Plastic processing equipment encompasses a range of machinery, including injection molding, blow molding, extrusion, compression molding, and rotational molding systems. These machines convert raw plastic materials into semi-finished or finished goods with desired shapes, sizes, and functional properties. Innovations like automated systems and 3D printing integration have enhanced production flexibility, enabling manufacturers to meet dynamic market requirements with improved efficiency and precision.

Regional Insights:

North America has emerged as a significant market, driven by industrial growth, technological advancement, and consumer demand for plastic products. Europe closely follows, supported by advanced manufacturing infrastructure and stringent quality standards. Asia-Pacific is witnessing rapid adoption due to large-scale manufacturing operations, government incentives, and rising demand for consumer goods and packaging solutions. Emerging regions in Latin America and Africa are also gradually investing in plastic processing technologies to meet industrial and consumer needs.

Key Trends & Forecast:

Several trends are shaping the plastic processing equipment market:

- Technological Advancements:Smart automation, IoT integration, and high-speed machinery are improving productivity and reducing operational costs.

- Sustainability Initiatives:Manufacturers are focusing on energy-efficient equipment and recyclable materials to reduce environmental impact.

- Rise in Packaging Demand:Growing consumption of packaged foods, beverages, and consumer goods is boosting the need for advanced plastic processing solutions.

- Customization & Flexibility:Equipment that allows precise control over product design, dimensions, and material composition is increasingly preferred by manufacturers.

Applications & End-Use Outlook:

Plastic processing equipment finds applications across various industries:

- Packaging:High-speed production capabilities allow for bottles, containers, films, and bags to meet diverse packaging needs.

- Automotive:Lightweight, durable plastic components enhance vehicle efficiency and design flexibility.

- Electronics & Electricals:Precision-molded plastic parts are crucial for electronic housings and components.

- Healthcare:Equipment is used to manufacture medical devices, prosthetics, and other plastic-based healthcare products.

- Consumer Goods:Plastic processing machinery supports production of household items, toys, and other consumer products.

Challenges & Market Restraints:

Despite strong growth, the market faces challenges:

- Environmental Concerns:Rising awareness about plastic waste and its environmental impact is driving demand for sustainable alternatives.

- Raw Material Fluctuations:Volatile prices and availability of petroleum-based plastics can affect production costs.

- Regulatory Compliance:Manufacturers must adhere to stringent quality and safety standards, increasing production complexity.

- Competition from Alternatives:Bioplastics and composite materials present viable alternatives, potentially reducing demand for conventional plastic processing equipment.

Country-Specific Insights:

- China:Rapid industrialization, government support, and a skilled workforce position China as a leading contributor to market growth.

- United States:Focus on sustainability, innovation, and eco-friendly manufacturing is driving adoption of advanced plastic processing equipment.

- Europe:Mature industrial infrastructure and emphasis on quality standards foster the use of high-precision processing machinery.

Category-Wise Insights:

- Polyethylene Terephthalate (PET):Widely used due to its flexibility, lightweight nature, and recyclability, PET is a popular material in packaging applications.

- High-Speed & Mass Production Equipment:Machines capable of handling large volumes efficiently are particularly valued in packaging and consumer goods sectors.

- Customization & Design Flexibility:Equipment that supports tailored product shapes and sizes is essential for industries requiring diverse product portfolios.

Conclusion:

The plastic processing equipment market is evolving with technological innovations, industrial growth, and rising demand for sustainable manufacturing solutions. Its applications span multiple sectors, from packaging and automotive to healthcare and consumer goods, making it a cornerstone of modern industrial production. As manufacturers continue to invest in advanced machinery and eco-friendly practices, the market is poised for sustained growth, delivering efficient, high-quality, and cost-effective plastic solutions across the globe.

Browse Full Report – https://www.factmr.com/report/plastic-processing-equipment-market