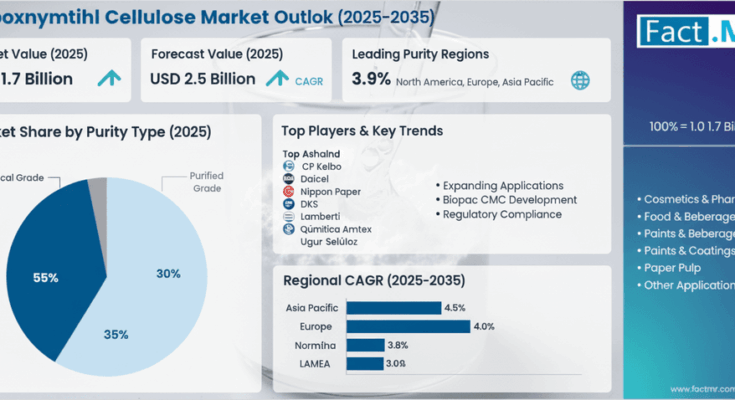

The global carboxymethyl cellulose (CMC) market is projected to grow from USD 1.7 billion in 2025 to USD 2.5 billion by 2035, registering a robust CAGR of 3.9%. This growth trajectory underscores a rising demand for high-purity technical grade CMC and specialized applications across food & beverage, pharmaceuticals, and industrial sectors worldwide. Manufacturers and industry leaders are intensifying investment into R&D and process innovation to capture expanding applications and meet stringent regulatory requirements.

Carboxymethyl Cellulose Market Growth Drivers and Opportunities

CMC’s multifunctional properties as a thickening, stabilizing, and emulsifying agent position it as a vital ingredient for food manufacturers and pharmaceutical formulators seeking to optimize product texture and efficacy. Market growth is fueled by accelerating global processed food demand and pharmaceutical modernization, each requiring superior CMC technology that delivers 50–70% higher thickening efficiency compared to conventional alternatives.

In food & beverage, the 39% market share evidences increasing reliance on CMC to enhance product consistency, improve shelf life, and replace synthetic thickeners with sustainable cellulose derivatives. Pharmaceutical usage, with a 27% market segment stake, reflects rising demand for high-purity excipients critical to advanced drug formulations, tablet binding, and controlled release.

Industrial applications—including oil drilling fluids and complex manufacturing systems—account for 34% of usage, indicating significant diversification in processing industries adopting advanced cellulose chemistry to meet evolving product standards.

Carboxymethyl Cellulose Market Segment and Regional Insights

The technical grade category dominates with a 52% share, favored for its superior chemical specifications, ease of integration, and consistent performance across manufacturing workflows. Industrial-grade and food/pharma-grade products constitute 29% and 19% of the market, respectively, reflecting the diverse purity levels tailored for precise application requirements.

Geographically, North America spearheads market expansion with the United States exhibiting a 4.3% CAGR through 2035, driven by government initiatives supporting food technology innovation and pharmaceutical compliance programs. Mexico follows closely, gaining momentum through industrial modernization and processing infrastructure scaling.

Europe, led by Germany’s 3.6% CAGR, reflects sophisticated manufacturing integration and stringent regulatory standards influencing CMC adoption. France, the UK, and other European countries align with strong food safety programs and manufacturing modernization fostering steady demand.

Asia Pacific, with key players from Japan, South Korea, and emerging Southeast Asian markets, is progressively adopting high-quality CMC variants to support precision processing, product development, and export-focused manufacturing.

TCarboxymethyl Cellulose Market echnological Innovations and Manufacturing Focus

Cutting-edge developments focus on refining cellulose extraction processes, enhancing powder and liquid form stability, and tailoring viscosity profiles to specific industrial use cases. Innovations include:

- Enhanced purity processing to meet pharmaceutical-grade excipient standards.

- Advanced dispersion systems improving solubility and application efficiency in food matrices.

- Integration of real-time quality monitoring tools and manufacturing analytics enabling optimized batch consistency and reduced production variability.

Leading manufacturers are investing heavily in chemical process intensification and automation, achieving scalable production capabilities that balance cost and quality while complying with evolving global regulatory frameworks.

Carboxymethyl Cellulose Market Competitive Landscape and Market Positioning

The market hosts approximately 10 to 12 significant players with moderate concentration. Leaders such as Ashland, CP Kelco, and Daicel leverage deep expertise in cellulose formulations and extensive partnerships across food processing and pharmaceutical sectors. These top firms command 30–35% of global market share, fortified by diverse product portfolios and comprehensive service capabilities.

Emerging players and regional specialists underscore increased competitiveness through innovation agility, localized production advantages, and customized technical support offered to manufacturing clients. The dynamic nature of the market favors suppliers capable of delivering flexible, high-performance CMC solutions addressing end-user precision needs while navigating complex compliance demands.

Carboxymethyl Cellulose Market Strategic Industry Implications

With the carboxymethyl cellulose market positioned to witness accelerated growth particularly between 2030 and 2035—accounting for 62.5% of overall expansion—industry leaders must proactively engage with end-user sectors through:

- Collaborative R&D programs to refine CMC application efficacy in food texture enhancement and pharmaceutical formulation.

- Investments in manufacturing modernization and scale to bridge supply-demand gaps in high-growth regions.

- Development of certification and quality assurance protocols ensuring product consistency across diverse regulatory environments.

- Extensions into digital manufacturing platforms facilitating adaptive production workflows responsive to market shifts.

Carboxymethyl Cellulose Market Conclusion

The global market for carboxymethyl cellulose represents a strategic growth opportunity for manufacturers committed to blending advanced chemistry with industrial practicality. The rising demand for technical grade and application-specific cellulose derivatives across food, pharmaceutical, and industrial markets confirms CMC as an essential ingredient of modern manufacturing innovation.

As global demand approaches USD 2.5 billion by 2035, companies that invest in chemical process advancements, compliance navigation, and customer-centric manufacturing solutions will be positioned to lead competitive market growth and unlock lasting value.

Manufacturers are invited to explore partnerships and innovation collaborations to amplify the potential of carboxymethyl cellulose in next-generation food and pharmaceutical products—ushering in a new era of processing excellence tailored to meet ever-stringent quality and performance standards.

This release reflects comprehensive market intelligence and offers actionable insights to industry leaders seeking to expand their footprint in the evolving carboxymethyl cellulose landscape.