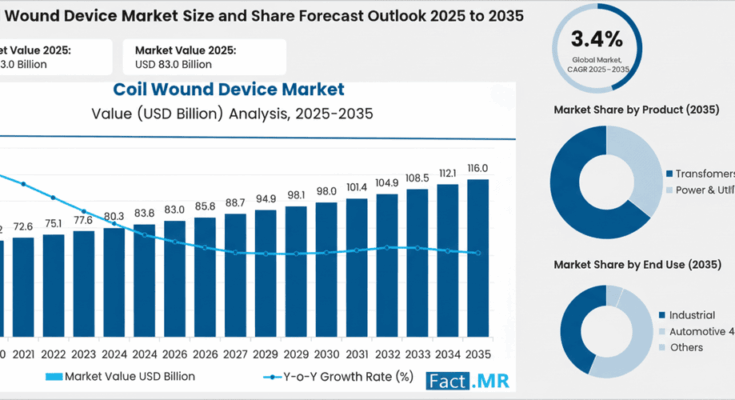

The global coil wound device market is poised for substantial growth, with a projected increase from USD 83.0 billion in 2025 to USD 116.0 billion by 2035, representing a CAGR of 3.4% over the forecast period. Market expansion is being driven by the rising demand for electrical infrastructure, industrial modernization, and precision-engineered power solutions across the globe.

Coil Wound Device Key Market Insights and Drivers

The decade-long market expansion is underpinned by the increasing need for advanced electrical systems and power management solutions in power generation, industrial applications, and transportation electrification. Specialized coil wound devices—ranging from transformers and inductors to motors and generators—enable manufacturers and utilities to optimize electrical systems while maintaining regulatory compliance and operational efficiency.

“Coil wound devices provide 50-70% better electrical performance than conventional alternatives,” said an industry analyst. “This performance advantage is critical as utilities and industrial companies increasingly prioritize energy efficiency, reliability, and compliance with evolving electrical standards.”

Three primary growth drivers are shaping the market trajectory:

-

Infrastructure Development: Rapid expansion of power grids and industrial electrical systems in emerging economies, particularly in India and China, is fueling demand for specialized coil wound solutions.

-

Government Initiatives: Policy support for electrification, industrial modernization, and renewable energy integration is accelerating adoption of advanced electrical components.

-

Technological Advancements: Innovations in precision winding technologies, quality control systems, and automated manufacturing platforms are improving component efficiency and reducing production complexity.

Coil Wound Device Segmental Insights: Transformers Lead the Way

By product type, transformers dominate the coil wound device market, accounting for approximately 55% of total market share in 2025. These devices are central to power conversion and management applications, offering high reliability and compatibility across industrial and utility environments. Inductors/chokes hold 25% market share, serving specialized circuit and filtering applications, while motors and generators comprise the remaining 20%, supporting mechanical power and industrial drive systems.

End-use segmentation indicates that the power and utilities sector represents the largest share at 40%, reflecting the critical role of coil wound devices in grid modernization and electrical infrastructure projects. The industrial sector follows with 25% market share, driven by automation and manufacturing optimization needs, while automotive and electronics applications account for 20% and 15%, respectively, fueled by electric vehicle adoption and advanced electronics integration.

Coil Wound Device Regional Market Outlook

Asia-Pacific emerges as the fastest-growing region, led by India with a CAGR of 5.0% and China at 4.0%, driven by ongoing investments in power infrastructure and industrial facilities. India’s growth is supported by government-backed electrification initiatives and the establishment of advanced manufacturing hubs in cities such as Mumbai, Chennai, Bangalore, and Pune. China is accelerating adoption through large-scale power modernization programs and industrial automation projects.

In mature markets, Germany leads Europe with a 3.2% CAGR, leveraging industrial expertise, advanced manufacturing, and regulatory frameworks. The United States shows steady growth at 3.0%, propelled by power infrastructure upgrades and manufacturing sector demands. Japan and South Korea maintain moderate growth at 2.5% and 2.9%, respectively, focusing on high-precision manufacturing and integration with existing electrical systems. Mexico and other Latin American countries are emerging markets, experiencing gradual adoption of coil wound technologies alongside industrial modernization initiatives.

Coil Wound Device Competitive Landscape

The coil wound device market is moderately consolidated, with leading players including ABB, Siemens Energy, Schneider, TDK, Vishay, Murata, Panasonic, Sumida, Wurth, and Delta. These companies maintain competitive advantages through comprehensive portfolios, specialized manufacturing capabilities, and deep integration with industrial and utility systems. Challenger companies focus on niche applications, regional presence, and technology-enabled solutions, while emerging players in India and China leverage local expertise and cost efficiencies to gain market share.

Coil Wound Device Opportunities for Stakeholders

Market expansion presents multiple avenues for stakeholders:

-

Governments can support adoption through infrastructure programs, tax incentives for advanced manufacturing, and skill development initiatives.

-

Industry Bodies may establish standards, certifications, and interoperability protocols to enhance system reliability and market trust.

-

Service Providers and Technology Players can expand offerings through advanced manufacturing platforms, predictive analytics, and integrated support services.

-

Investors have opportunities to fund capacity expansion, technological innovation, and regional market development, particularly in high-growth Asia-Pacific markets.

Coil Wound Device Outlook

With projected absolute market growth of USD 33.0 billion by 2035, the coil wound device sector presents a compelling opportunity for manufacturers, utility operators, and industrial companies seeking to enhance system performance, operational reliability, and regulatory compliance. As governments and private stakeholders invest in infrastructure, innovation, and talent development, the market is expected to evolve into a sophisticated, technology-driven ecosystem that supports global electrical transformation.

Browse Full Report : https://www.factmr.com/report/coil-wound-device-market