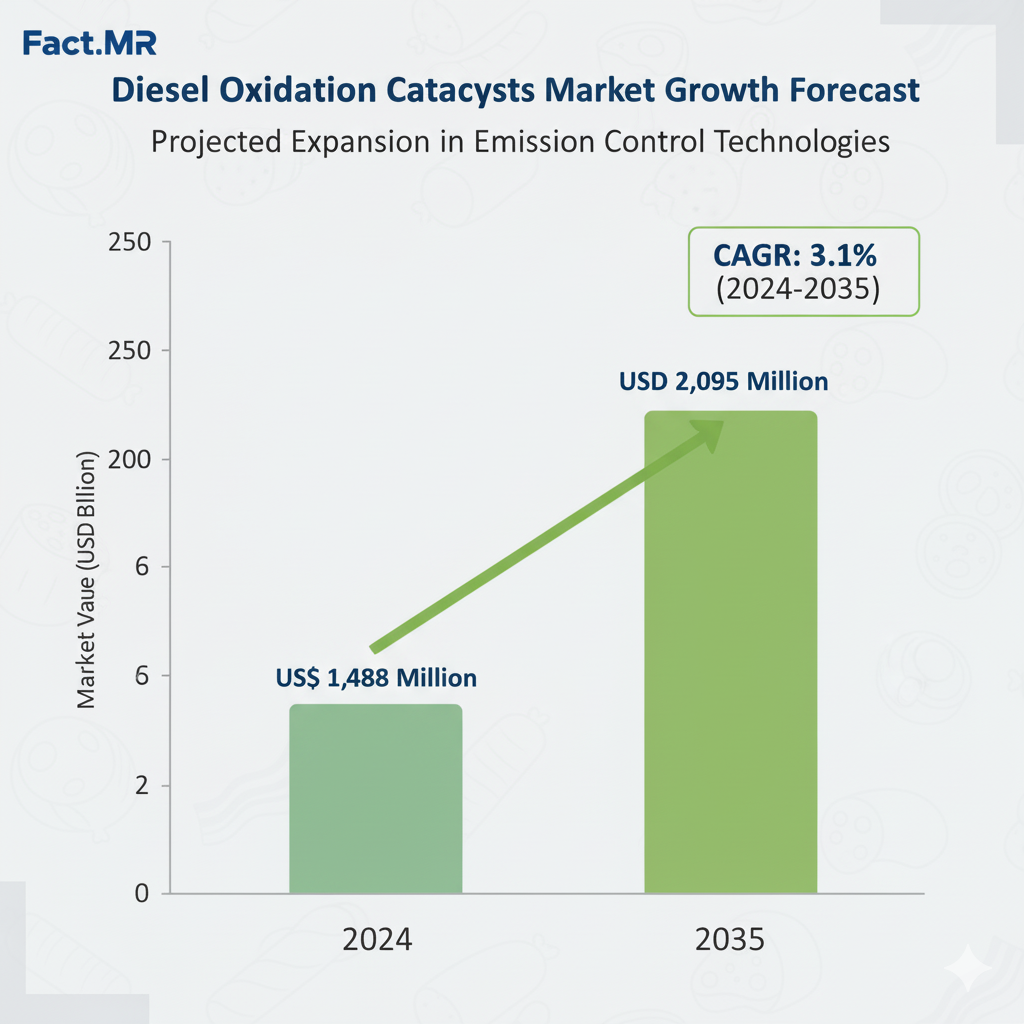

The global Diesel Oxidation Catalysts Market is projected value at US$ 1,488 million in 2024 and expand at a CAGR of 3.1% to end up at US$ 2,095 million by 2035.As environmental concerns intensify and emission regulations tighten worldwide, the demand for advanced catalyst technologies is surging—positioning leading manufacturers such as BASF SE, Johnson Matthey PLC, Umicore S.A., and Corning Incorporated at the forefront of the global clean energy transition.

Rising Emission Norms Drive Market Momentum:

Diesel oxidation catalysts play a pivotal role in mitigating harmful emissions from diesel engines by oxidizing carbon monoxide (CO) and unburned hydrocarbons (HC) into less harmful compounds such as carbon dioxide and water. This catalytic process is essential for industries striving to meet international emission standards, including Euro VI, EPA Tier 4, and China VI norms.

From heavy-duty vehicles to industrial machinery and marine vessels, DOCs are witnessing widespread adoption. The automotive segment remains a dominant end-use area, as both light and heavy-duty vehicle manufacturers integrate DOC systems to achieve compliance with evolving environmental mandates and enhance fuel efficiency.

Fact.MR’s research highlights that between 2025 and 2035, OEM applications are projected to generate an absolute dollar opportunity worth US$ 338.1 million, underscoring strong industry reliance on advanced DOC systems.

Technological Innovations Reshaping the Catalyst Landscape:

The report identifies technological innovation as a key catalyst for market growth. Manufacturers are increasingly investing in next-generation catalyst materials, including palladium-based and nanostructured coatings, to improve oxidation efficiency, durability, and temperature resilience.

Leading players such as BASF and Umicore are spearheading breakthroughs in sustainable catalyst formulations. For instance, BASF’s 2023 innovations in commercial vehicle catalyst technology enhance emissions conversion efficiency, enabling compliance with next-generation standards. Similarly, Umicore’s new production facilities for low-emission catalyst systems reinforce its position in the sustainable mobility ecosystem.

MIRATECH’s enhanced DOC maintenance program further demonstrates how aftersales support is becoming integral to maximizing catalyst life expectancy, ensuring both economic and environmental gains for end-users.

Regional Dynamics: North America and China Lead the Transition:

Regional performance data from the Fact.MR report highlights North America’s commanding 35.9% market share in 2024, driven by stringent EPA emission standards and expanding investments in cleaner transportation systems. The North American market, estimated at US$ 555 million in 2025, is expected to grow at a CAGR of 3.2%, supported by policy-driven initiatives in sustainable logistics and industrial modernization.

The United States is projected to remain a focal point of DOC adoption, with its market value reaching US$ 477 million by 2025. Stricter federal and state-level emission controls, particularly targeting heavy-duty vehicles, continue to create new opportunities for DOC manufacturers.

Meanwhile, China, registering a 2.9% CAGR between 2025 and 2035, presents lucrative prospects as its industrial sector transitions toward cleaner diesel technologies. Rapid urbanization, rising freight demand, and the government’s “Blue Sky Protection Plan” are accelerating the integration of DOC systems in transportation and industrial applications. By 2035, China’s DOC market is expected to reach US$ 461 million, solidifying its status as a major growth hub for catalyst innovation.

Market by Type: Hydrocarbon (HC) Segment Dominates:

Within product segmentation, Hydrocarbon (HC)-based DOCs command a 41.9% share, valued at US$ 648 million in 2025. This dominance is attributed to their superior efficiency in oxidizing unburned hydrocarbons and particulate matter—key pollutants in diesel exhaust streams. As global regulatory frameworks demand lower permissible emission levels, this segment will continue to drive both R&D and commercial activity in the coming decade.

Challenges and Competitive Pressures:

Despite a favorable outlook, the DOC market faces challenges, particularly related to high production costs driven by fluctuating precious metal prices (platinum, palladium, and rhodium) and complex manufacturing processes. These cost pressures are pushing smaller manufacturers to consolidate or partner with larger entities to maintain competitiveness.

Nevertheless, Fact.MR notes that sustained investment in process optimization, advanced substrate design, and material recovery technologies can help mitigate these cost challenges while improving overall catalyst performance.

Future Outlook: A Decade of Sustainable Innovation:

The next decade (2025–2035) is expected to witness a strategic transformation across the DOC industry as stakeholders align with global net-zero goals.

– Short-Term (2025–2028): Rapid adoption of new DOC technologies to meet emerging emission norms and strengthen OEM partnerships.

– Medium-Term (2028–2032): Expansion of catalyst applications across hybrid and alternative fuel vehicles as manufacturers pursue efficiency and durability.

– Long-Term (2032–2035): Integration of smart monitoring systems in DOCs, leveraging IoT and AI to optimize performance and lifespan.

Industry Leaders Steering the Market:

Prominent companies shaping the global diesel oxidation catalysts landscape include:

BASF SE, Johnson Matthey PLC, Umicore S.A, Corning Incorporated, Bosal International, Cataler Corp, CDTi Advanced Materials, MIRATECH, AirFlow Catalyst Systems, Dinex, DLC International, Nett Technologies Inc., and Hypercat ACP.

These companies are advancing through mergers, capacity expansions, and strategic alliances to meet the surging global demand for emission control systems. The ongoing wave of investments in cleaner technologies underscores the industry’s unified vision toward sustainable and responsible mobility.

The Diesel Oxidation Catalysts Market is on a transformative path, balancing technological sophistication with sustainability imperatives. With a projected valuation exceeding US$ 2 billion by 2035, the market reflects both industrial resilience and a collective drive to mitigate the environmental impact of diesel emissions.

As emission regulations continue to evolve and cleaner propulsion technologies gain traction, industry leaders and innovators will play a decisive role in shaping the future of air quality, industrial efficiency, and sustainable transportation.

Browse Full Report- https://www.factmr.com/report/diesel-oxidation-catalysts-market