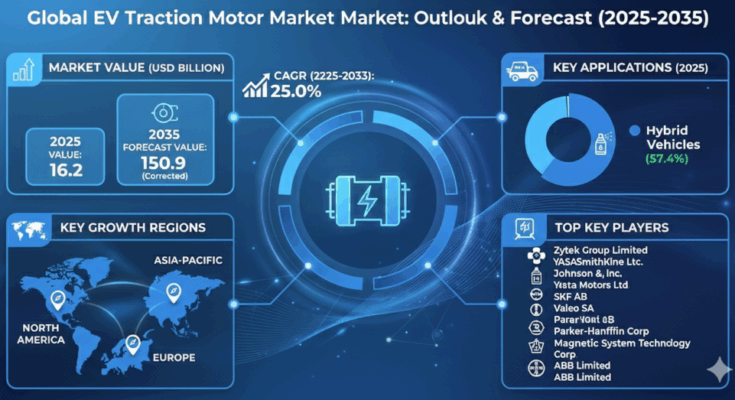

The automotive industry is undergoing a dramatic shift as electric vehicles (EVs) move from niche alternatives to mainstream transportation solutions. At the center of this transformation is the EV traction motor — a vital component responsible for converting electrical energy into mechanical motion. As global demand for sustainable mobility rises, the EV traction motor market is gaining strong momentum, driven by technological innovation, regulatory support, and evolving consumer preferences.

What Is an EV Traction Motor?

An EV traction motor is the propulsion system that powers an electric vehicle by transforming energy stored in batteries into rotational force that drives the wheels. Unlike traditional internal combustion engines, traction motors deliver instant torque, enabling smoother acceleration and a quieter driving experience. Their efficiency and responsiveness make them a defining feature of modern electric mobility.

Several types of traction motors are used in EVs, including permanent magnet synchronous motors, induction motors, and switched reluctance motors. Each offers unique benefits in terms of cost, durability, performance, and efficiency. Automakers select motor technologies based on vehicle requirements such as range, power output, and overall design architecture.

Market Overview

The EV traction motor market is expanding rapidly as automakers accelerate electrification strategies. Growing environmental awareness and stricter emissions regulations are encouraging both manufacturers and consumers to shift toward cleaner transportation options. As EV production scales up globally, the need for reliable, high-performance traction motors continues to rise.

Modern traction motors are designed with a focus on compactness, energy efficiency, and high power density. Continuous advancements in engineering have enabled manufacturers to create motors that are lighter yet more powerful, helping improve vehicle range while maintaining strong performance.

The market also benefits from improvements in manufacturing processes, allowing suppliers to produce motors with greater precision and consistency. As production volumes increase, economies of scale are expected to make traction motor technologies more accessible across a broader range of vehicle segments.

Key Growth Drivers

Rapid Adoption of Electric Vehicles

The surge in EV adoption is the most significant factor driving traction motor demand. Governments worldwide are promoting electrification through incentives, emissions targets, and investments in charging infrastructure. This supportive ecosystem is encouraging automakers to expand their electric portfolios, directly boosting the need for advanced motor systems.

Superior Performance Capabilities

Traction motors provide immediate torque, allowing vehicles to accelerate quickly without the delays associated with traditional engines. They also support regenerative braking, which captures energy during deceleration and feeds it back into the battery. These capabilities enhance efficiency while extending driving range — a critical consideration for EV buyers.

Advancements in Motor Technology

Innovation continues to redefine traction motor design. Engineers are exploring new configurations that deliver higher efficiency while reducing dependence on scarce materials. High-performance motor architectures with improved thermal management are helping vehicles maintain consistent output even under demanding conditions.

Expansion of Commercial Electric Mobility

While passenger EVs dominate headlines, commercial electric vehicles — including buses, delivery vans, and trucks — are emerging as major contributors to traction motor demand. Fleet operators are increasingly transitioning to electric platforms to lower operating costs and meet sustainability goals.

Market Segmentation

The EV traction motor market can be analyzed across multiple dimensions.

By Motor Type: Permanent magnet motors are widely favored for their high efficiency and compact size, making them suitable for passenger vehicles. Induction motors are valued for their robustness and reduced reliance on rare earth materials, while switched reluctance motors are gaining attention for their durability and simplified construction.

By Power Output: Motors vary significantly in power ratings to accommodate different vehicle categories. Smaller motors typically serve compact city cars, while higher-capacity units are designed for SUVs, performance vehicles, and commercial transport.

By Vehicle Category: Battery electric vehicles represent the largest share of traction motor usage, but hybrids and plug-in hybrids also rely on motor systems to enhance fuel efficiency and reduce emissions.

Regional Landscape

The traction motor market demonstrates strong global expansion, with Asia-Pacific emerging as a key manufacturing and consumption hub. The region benefits from large-scale vehicle production, supportive government policies, and an established supply chain for EV components. Rapid urbanization and growing consumer acceptance of electric mobility further reinforce market growth.

North America is witnessing rising investments in EV production facilities and component manufacturing. Automakers are focusing on localizing supply chains to strengthen resilience while meeting increasing demand for electric vehicles.

Europe remains at the forefront of sustainability initiatives, with strict emissions standards pushing manufacturers toward electrified platforms. Strong research and development capabilities in the region continue to foster innovation in motor technologies.

Meanwhile, developing regions are gradually embracing electrification as infrastructure improves and awareness grows. These markets present long-term opportunities for traction motor manufacturers seeking geographic diversification.

Emerging Trends

High Power Density Motors: Automakers are prioritizing motors that deliver greater output without significantly increasing weight. This approach enhances driving range and supports performance-oriented EV designs.

Integrated Drive Units: Combining the motor, inverter, and transmission into a single compact system is becoming increasingly popular. This integration reduces complexity, improves efficiency, and optimizes space within the vehicle.

Smart Motor Control: Advanced software and electronic controls are enabling more precise energy management, enhancing both responsiveness and reliability.

Sustainable Engineering: Manufacturers are exploring ways to minimize environmental impact by improving recyclability and reducing reliance on resource-intensive materials.

Challenges Facing the Market

Despite its strong outlook, the EV traction motor market faces several hurdles. Fluctuations in raw material prices can impact production costs, particularly for components used in magnets and electronic systems. Managing heat in high-performance motors is another technical challenge, requiring sophisticated cooling solutions to ensure longevity.

Additionally, scaling production while maintaining quality standards demands significant investment. As competition intensifies, companies must balance affordability with innovation to remain competitive.

Future Outlook

The future of the EV traction motor market is closely aligned with the broader electrification movement reshaping the automotive sector. As vehicles become smarter, more efficient, and increasingly connected, traction motors will remain central to their operation.

Ongoing research is expected to deliver motors that are lighter, more powerful, and even more energy-efficient. With continued policy support, technological breakthroughs, and expanding consumer acceptance, the traction motor will play a defining role in the next era of transportation.

In the evolving mobility landscape, traction motors are more than just mechanical components — they are the driving force behind cleaner, smarter, and more sustainable travel.

Browse Full Report – https://www.factmr.com/report/336/ev-traction-motor-market