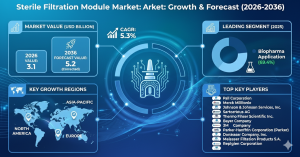

The sterile filtration module market plays a critical role in ensuring product safety, quality, and regulatory compliance across industries where contamination control is essential. Sterile filtration modules are widely used to remove microorganisms, particulates, and impurities from liquids and gases without altering product composition. As industries such as pharmaceuticals, biotechnology, food and beverages, and medical devices continue to prioritize hygiene and process integrity, demand for advanced sterile filtration solutions is steadily increasing.

Growing emphasis on quality assurance, coupled with stringent regulatory standards, is positioning sterile filtration modules as indispensable components in modern manufacturing and processing environments.

Market Overview

Sterile filtration modules are engineered filtration systems designed to achieve high levels of microbial retention while maintaining efficient flow rates and product stability. These modules typically incorporate membrane-based filters made from materials such as polyethersulfone, polyvinylidene fluoride, and polytetrafluoroethylene. They are available in various configurations to suit different process requirements, including liquid filtration and gas sterilization.

The market is characterized by continuous innovation aimed at improving filtration efficiency, durability, and compatibility with a wide range of process fluids. Manufacturers are focusing on modular designs that allow easy integration into existing production lines, reducing downtime and enhancing operational flexibility. Sterile filtration modules are increasingly being adopted as single-use or reusable systems depending on application needs and compliance requirements.

Key Growth Drivers

One of the primary drivers of the sterile filtration module market is the expanding pharmaceutical and biopharmaceutical industry. The growing production of injectable drugs, vaccines, biologics, and cell-based therapies requires reliable sterile filtration to ensure patient safety and product consistency.

Another key driver is the rising adoption of aseptic processing techniques. Sterile filtration modules enable manufacturers to maintain sterility without the need for high-temperature sterilization, which can degrade sensitive products. This makes them particularly valuable in applications involving heat-sensitive formulations.

Increased focus on food safety and beverage quality is also contributing to market growth. Sterile filtration is widely used to extend shelf life, preserve flavor, and meet hygiene standards without the use of chemical preservatives. Additionally, heightened awareness of contamination risks in healthcare and laboratory settings is driving demand for dependable filtration solutions.

Regional Insights

North America remains a prominent market for sterile filtration modules, supported by advanced manufacturing capabilities and strong regulatory oversight in pharmaceutical and healthcare sectors. The region’s emphasis on innovation and quality compliance continues to drive adoption of high-performance filtration technologies.

Europe represents another key market, driven by strict hygiene regulations and a well-established life sciences industry. Manufacturers in the region are investing in advanced filtration systems to comply with evolving standards related to product sterility and environmental safety.

The Asia-Pacific region is emerging as a significant growth area due to expanding pharmaceutical manufacturing, increasing healthcare investments, and rapid industrialization. Countries in this region are strengthening their production infrastructure, creating new opportunities for sterile filtration module suppliers.

Key Trends and Market Dynamics

A major trend shaping the sterile filtration module market is the increasing adoption of single-use filtration systems. These solutions reduce the risk of cross-contamination, eliminate cleaning validation requirements, and enhance operational efficiency, particularly in biopharmaceutical manufacturing.

Another notable trend is the development of high-capacity and low-protein-binding membranes. These innovations improve filtration performance while minimizing product loss, making them suitable for high-value biologics and specialty formulations.

Automation and digital monitoring are also gaining traction. Advanced sterile filtration modules are being integrated with sensors and monitoring systems that provide real-time data on pressure, flow rate, and filter integrity. This supports predictive maintenance and enhances process control.

Sustainability considerations are influencing product design as well. Manufacturers are exploring recyclable materials and energy-efficient filtration solutions to align with environmental goals without compromising performance.

Applications and End-Use Outlook

Sterile filtration modules are extensively used in pharmaceutical and biotechnological manufacturing for applications such as formulation, filling, and final product sterilization. They are critical in maintaining aseptic conditions throughout production processes.

In the food and beverage industry, these modules are used for microbial stabilization of liquids such as dairy products, beverages, and liquid ingredients. Their ability to preserve product quality while ensuring safety makes them highly valuable in this sector.

Medical device manufacturing, laboratories, and research institutions also represent important end-use segments. Sterile filtration modules are used to sterilize process gases, culture media, and laboratory reagents, supporting reliable and contamination-free operations.

Competitive Landscape

The sterile filtration module market is moderately competitive, with established filtration technology providers and specialized manufacturers offering a wide range of products. Key competitive strategies include product innovation, customization, and expansion of application-specific solutions.

Companies are investing in research and development to enhance membrane performance, extend filter life, and improve compatibility with diverse process conditions. Strategic collaborations with pharmaceutical manufacturers and system integrators are further strengthening market presence and customer reach.

Future Outlook

The future of the sterile filtration module market is expected to remain strong, driven by rising demand for contamination-free processing and continued expansion of regulated industries. Advancements in membrane technology, automation, and sustainable design are likely to shape the next generation of sterile filtration solutions.

As industries place greater emphasis on quality, safety, and regulatory compliance, sterile filtration modules will continue to be essential components of modern manufacturing systems. Access to comprehensive market intelligence from trusted research platforms such as Fact.MR can help stakeholders identify emerging opportunities and develop strategies aligned with evolving industry requirements.

Browse Full Report – https://www.factmr.com/report/sterile-filtration-module-market