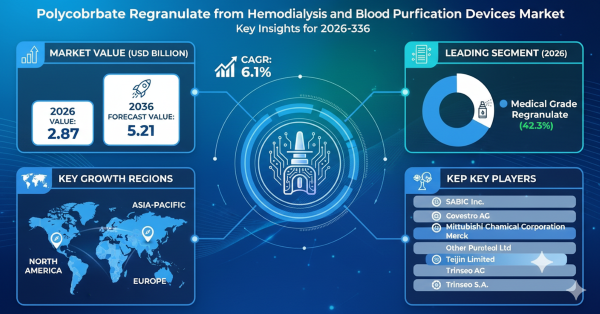

The global healthcare sector is undergoing a critical transformation as sustainability, regulatory compliance, and material efficiency take center stage. Among emerging solutions, the polycarbonate regranulate from hemodialysis and blood purification devices market is gaining increasing attention. With growing volumes of medical plastic waste generated from life-saving therapies, the reuse of high-performance polymers such as polycarbonate presents a compelling opportunity to support circular economy principles while maintaining strict quality and safety standards.

Market Overview

Polycarbonate is widely used in hemodialysis and blood purification devices due to its strength, transparency, heat resistance, and biocompatibility. Components such as housings, connectors, and filtration casings rely heavily on this polymer. After controlled collection and processing, polycarbonate waste from these devices can be recycled into regranulate suitable for reuse in selected applications.

The market focuses on recovering post-use medical-grade polycarbonate through specialized recycling processes that ensure material integrity and compliance with regulatory frameworks. This approach not only reduces dependency on virgin plastics but also helps healthcare systems and manufacturers manage waste more responsibly.

Key Growth Drivers

One of the primary drivers of this market is the rising global demand for dialysis and blood purification treatments. As treatment volumes increase, so does the generation of polymer-based medical waste, creating an urgent need for sustainable disposal and recycling solutions.

Another important growth factor is the increasing emphasis on sustainable healthcare manufacturing. Medical device manufacturers are under pressure to lower their environmental footprint while maintaining product safety and performance. Regranulated polycarbonate offers a viable pathway to achieve these goals, especially for non-critical or secondary medical and industrial applications.

Additionally, advancements in recycling technologies—such as improved sorting, decontamination, and polymer stabilization—are making it possible to recover high-quality regranulate from complex medical devices.

Regulatory and Compliance Landscape

Recycling materials from medical devices requires strict adherence to regulatory guidelines related to hygiene, traceability, and material performance. Regulatory bodies across major regions are gradually supporting controlled recycling frameworks, provided that material recovery processes meet stringent safety and quality requirements.

Compliance-driven innovation is encouraging stakeholders to invest in closed-loop recycling systems, where materials are collected, processed, and reused under validated conditions. This regulatory clarity is strengthening confidence in polycarbonate regranulate derived from medical sources.

Regional Insights

Europe stands at the forefront of this market due to its strong focus on circular economy policies, medical waste management, and sustainable manufacturing. The region’s structured healthcare systems and recycling infrastructure enable controlled recovery of polymer materials from medical devices.

North America follows closely, supported by advanced dialysis infrastructure, increasing adoption of sustainable healthcare practices, and growing collaboration between recyclers and medical device manufacturers. Industry-led initiatives are playing a key role in developing standardized recycling pathways.

Asia-Pacific is emerging as a promising region, driven by expanding dialysis patient populations, growing healthcare investments, and rising awareness of medical plastic waste challenges. As recycling capabilities improve, the region is expected to play a larger role in material recovery and reuse.

Key Trends and Market Evolution

A major trend shaping the market is the development of medical-to-industrial recycling pathways. While regranulated polycarbonate may not always return to critical medical applications, it is increasingly being used in industrial components, electronics housings, automotive parts, and construction materials.

Another notable trend is the emphasis on material traceability and quality assurance. End users are demanding detailed documentation regarding material origin, processing methods, and performance consistency to ensure reliability.

Collaboration across the value chain is also intensifying. Medical device manufacturers, dialysis service providers, recyclers, and material processors are forming partnerships to establish efficient collection and recycling ecosystems.

Applications and End-Use Outlook

Regranulated polycarbonate derived from hemodialysis and blood purification devices finds application in a variety of downstream sectors. Industrial manufacturing remains a key end-use area, where the material’s durability and thermal resistance are highly valued.

The electrical and electronics sector is another important application area, utilizing recycled polycarbonate for enclosures, panels, and structural components. Automotive and mobility-related applications are also adopting regranulate to support lightweighting and sustainability goals.

While direct reuse in high-risk medical devices remains limited, controlled reuse in non-invasive medical equipment and accessories is gradually being explored under strict regulatory oversight.

Competitive Landscape

The market consists of specialized recyclers, polymer processors, and sustainability-focused material suppliers. Companies are investing in proprietary recycling technologies that ensure consistent quality and regulatory compliance. Competitive differentiation is increasingly based on processing expertise, certification capabilities, and long-term partnerships with healthcare providers.

Innovation in polymer purification and stabilization continues to enhance the performance potential of recycled polycarbonate, making it more attractive to a broader range of industries.

Conclusion

The polycarbonate regranulate market from hemodialysis and blood purification devices represents a significant step toward sustainable healthcare manufacturing. By transforming medical plastic waste into valuable material resources, this market supports environmental responsibility without compromising performance standards. As regulatory clarity improves and recycling technologies advance, the role of polycarbonate regranulate is expected to expand across multiple industries.

Browse Full Report – https://www.factmr.com/report/polycarbonate-regranulate-from-hemodialysis-and-blood-purification-devices-market