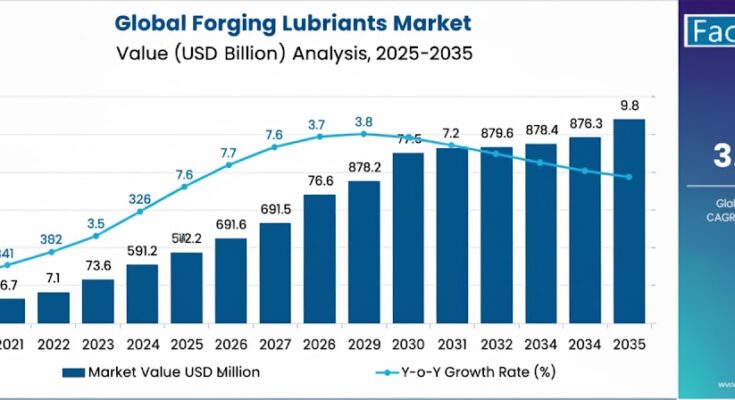

The global forging lubricants market, valued at USD 6.7 billion in 2025, is projected to grow at a compound annual growth rate (CAGR) of 3.7%, reaching USD 9.8 billion by 2035. This growth is fueled by the adoption of nanotechnology-enhanced lubricants, environmental regulations, and rising demand from automotive, aerospace, and industrial forging operations.

Technological Advancements Driving Performance

Nanotechnology is transforming lubricant performance, offering enhanced wear protection, reduced friction, and improved thermal stability. These innovations extend die life, reduce equipment downtime, and improve production efficiency, particularly in precision forging applications. High-performance lubricants are now essential for shaping alloys such as titanium, aluminum, and high-strength steels used in automotive and aerospace sectors.

Environmental Compliance and Green Innovation

Stricter environmental regulations in Europe, North America, and Asia are encouraging the adoption of bio-based, water-soluble, and low-residue lubricants. Manufacturers are reformulating products to meet VOC limits and biodegradability standards, aligning with sustainable production practices. These eco-friendly solutions are increasingly favored by OEMs and industrial end-users, driving market expansion.

Market Dynamics and Drivers

1. Industrial Growth: Rising automotive, aerospace, and heavy machinery production in Asia-Pacific and Latin America supports lubricant demand.

2. Specialty Alloys: Forging of lightweight metals like aluminum and titanium requires advanced lubricants with high thermal stability and anti-sticking properties.

3. Process Optimization: Hydraulic presses and precision forging lines benefit from tailored lubricants that reduce wear and improve tool life.

4. Sustainability: Water-based and bio-based lubricants help companies meet regulatory compliance and ESG goals.

5. R&D Investments: Continuous innovation in additive technologies enhances product performance and application versatility.

Segment Overview

By Lubricant Type: Water-based lubricants are the fastest-growing segment due to environmental advantages and compatibility with automated systems, while oil-based and coating-based lubricants remain widely used for high-temperature applications.

By Application: Hot forging dominates due to its demand in automotive and aerospace industries, while cold forging maintains steady growth for smaller, precision components.

By Material: Titanium and aluminum alloys drive premium lubricant use, particularly in aerospace, medical, and EV applications.

By Operation: Hydraulic presses are preferred for precision forging and complex geometries, creating a high-value segment for advanced lubricants.

Regional Insights

Asia-Pacific: Leading growth region with China, India, and South Korea driving high consumption in automotive, aerospace, and industrial forging.

North America: Growth at 4.0% CAGR, supported by automotive, EV production, and aerospace manufacturing, with focus on water-based and eco-friendly lubricants.

Europe: Germany, France, UK, and Italy emphasize precision engineering and sustainability, encouraging adoption of advanced, low-residue lubricants.

Latin America and MEA: Infrastructure development and industrialization spur demand for high-performance forging lubricants, though growth is moderated by cost sensitivity and technology adoption rates.

Competitive Landscape

Major players include Henkel Corporation, Chem-Trend L.P., Quaker Houghton, Houghton International Inc., and Moresco Corporation. Henkel leads with 18% market share through its BONDERITE® line of water-based and graphite-based lubricants. Chem-Trend commands 15% globally with high-performance FORGE RELEASER™ and TRENZOL™ products. Quaker Houghton holds 12%, focusing on synthetic and sustainable solutions, while Moresco maintains a 9% share in Asia-Pacific with niche specialty products.

Recent Developments

In 2024, leading manufacturers expanded capacity and introduced sustainable lubricant lines to meet regulatory requirements and specialty forging needs. Partnerships with automotive OEMs and aerospace manufacturers enabled tailored formulations for high-temperature, lightweight, and precision alloy applications.

Browse Full Report : https://www.factmr.com/report/1078/forging-lubricants-market

Market Outlook

Over the next decade, forging lubricants will evolve beyond conventional formulations, focusing on sustainability, high performance, and compatibility with advanced manufacturing techniques. Growth will be fueled by precision forging, lightweight alloy adoption, and regulatory compliance in developed markets, alongside industrial expansion in emerging economies.