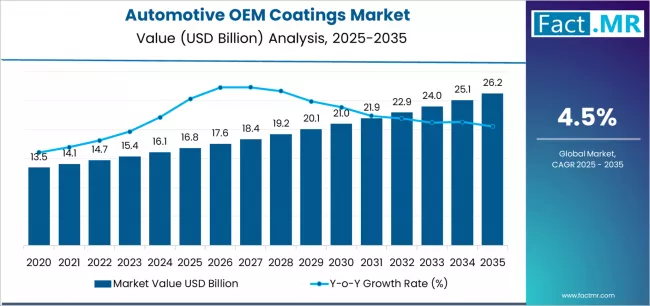

The automotive OEM coatings market is experiencing steady growth as manufacturers increasingly prioritize vehicle aesthetics, corrosion protection, and environmental compliance. Automotive coatings are no longer just surface finishes—they are essential components of modern vehicle manufacturing, ensuring durability, performance, and regulatory adherence. Rising vehicle production volumes, the adoption of advanced coating technologies, and the expansion of electric and lightweight vehicles are driving the demand for innovative OEM coating solutions worldwide.

Market Overview

OEM coatings are specialized materials applied during vehicle manufacturing to protect surfaces, enhance visual appeal, and improve long-term durability. These coatings include primers, basecoats, clearcoats, and resins designed to meet stringent industry standards. Automotive manufacturers are increasingly adopting multi-layer coating systems that combine protective and aesthetic functions, delivering superior corrosion resistance, gloss retention, and scratch protection.

Technological advancements in coating chemistry, including water-based systems, powder coatings, and electrocoat applications, are shaping the market. These innovations enhance application efficiency, reduce volatile organic compound (VOC) emissions, and align with sustainability initiatives, supporting environmentally responsible manufacturing practices.

Key Drivers of Market Growth

- Increasing Vehicle Production

Growing global automotive production has heightened the need for protective coatings in both passenger and commercial vehicles. OEM coatings ensure surface integrity and long-term performance across diverse vehicle platforms. - Emphasis on Vehicle Aesthetics

Consumer preferences for visually appealing vehicles have prompted manufacturers to invest in high-quality coatings that provide vibrant colors, gloss retention, and uniform finishes. Coatings play a critical role in brand differentiation and customer satisfaction. - Technological Advancements in Coating Systems

The development of advanced primers, epoxy resins, and multi-layer coatings supports superior adhesion, corrosion resistance, and durability. Innovative systems such as electrocoat deposition and two-component clearcoats enhance efficiency and coating performance. - Environmental Regulations and VOC Compliance

Stricter environmental standards are driving the adoption of low-emission water-based coatings and powder coatings. Automotive OEMs are increasingly selecting sustainable coating solutions to comply with regulatory requirements without compromising performance. - Expansion of Electric and Lightweight Vehicles

Electric and lightweight vehicle segments require specialized coating technologies that adhere to new materials like aluminum and composites. These vehicles demand coatings that provide protection while maintaining weight efficiency and performance standards.

Market Segmentation

By Product Type

- Primer: Primers dominate the market by providing corrosion protection, adhesion enhancement, and a smooth base for subsequent coatings. Advanced electrocoat primers offer uniform coverage and improved durability.

- Basecoat and Clearcoat: Basecoats deliver color and aesthetic appeal, while clearcoats provide gloss, UV protection, and scratch resistance. These layers are integral to vehicle finish quality and longevity.

By Resin Type

Epoxy resins are widely adopted for their balance of adhesion, corrosion protection, and chemical resistance. Other resin technologies, including polyurethane and acrylic-based systems, complement epoxy formulations for specialized applications.

By Application

Automotive OEM coatings are used across passenger cars, commercial vehicles, and specialty vehicles. Multi-layer coating systems are increasingly standard, combining primers, basecoats, and clearcoats to optimize both appearance and protection.

By End-User

The primary end-users include automotive OEMs, specialty vehicle manufacturers, and assembly facilities. These stakeholders prioritize coatings that improve production efficiency, reduce post-production defects, and enhance overall vehicle quality.

Regional Insights

North America

North America remains a key market, driven by well-established automotive manufacturing infrastructure, high consumer demand for premium vehicles, and widespread adoption of advanced coating technologies.

Europe

Europe emphasizes regulatory compliance and sustainability, promoting water-based and low-VOC coatings. Manufacturers focus on durability, finish quality, and environmental performance.

Asia-Pacific

Asia-Pacific represents a high-growth region, supported by expanding automotive production, growing consumer markets, and rapid industrialization. Local manufacturing clusters in China, India, and Southeast Asia are driving demand for innovative OEM coatings.

Other Regions

Latin America, the Middle East, and Africa are gradually adopting advanced coating solutions as vehicle production and assembly infrastructure expand, offering new opportunities for market growth.

Key Trends and Opportunities

Advanced Coating Formulations

The integration of nano-particle technology, high-solids coatings, and self-healing formulations improves corrosion resistance, scratch protection, and aesthetic longevity.

Electrocoat and Automated Application Systems

Electrocoat deposition and robotic spray systems ensure uniform coating application, enhancing production efficiency and quality consistency.

Sustainability Initiatives

The shift toward water-based and powder coating technologies aligns with global sustainability efforts, reducing VOC emissions and environmental impact.

Electric Vehicle Coatings

The growing electric vehicle market demands coatings compatible with lightweight materials and specialized battery components, creating opportunities for tailored OEM solutions.

Conclusion

The automotive OEM coatings market is poised for sustained growth as manufacturers continue to balance vehicle aesthetics, durability, and environmental compliance. Advanced coating technologies, including multi-layer systems, water-based formulations, and automated application processes, are reshaping the landscape.

As electric and lightweight vehicles become mainstream, demand for specialized coating solutions will expand further. OEM coatings will remain a critical factor in achieving high-quality vehicle finishes, corrosion resistance, and sustainable production practices. By investing in innovative coating solutions, automotive manufacturers can ensure superior vehicle performance, satisfy consumer expectations, and meet increasingly stringent regulatory standards.

The future of the automotive OEM coatings market lies in technological innovation, sustainability, and adaptability to evolving automotive materials, positioning it as an essential component of modern vehicle manufacturing.

Browse Full Report – https://www.factmr.com/report/automotive-oem-coatings-market