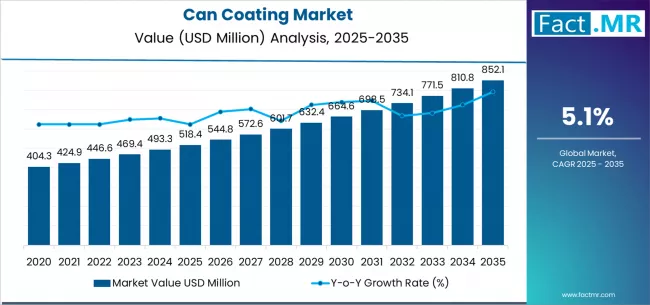

The global Can Coatings Market is experiencing steady expansion, driven by growing consumption of packaged food and beverages, rising demand for aerosol-based products, and continuous improvements in metal packaging technologies. In 2024, the market is valued at approximately USD 2.61 billion, and it is projected to reach about USD 3.61 billion by 2034, reflecting a consistent CAGR of around 3.3% over the forecast period.

This upward trajectory highlights the essential role of can coatings in maintaining product integrity, preventing contamination, enhancing corrosion resistance, and ensuring the long-term preservation of packaged goods.

Key Market Segments & Trends

By Resin Type

- Acrylic Coatings:

Acrylic formulations currently lead the market due to their favorable safety profile, excellent aesthetic qualities, and strong performance as BPA-free alternatives. With growing regulatory pressure and rising consumer awareness around packaging safety, acrylic coatings are projected to continue capturing a significant share of overall demand.

- Epoxy, Polyester & Others:

Epoxy coatings still retain a presence due to their long-standing performance advantages; however, many manufacturers are moving toward epoxy alternatives due to changing safety regulations. Polyester coatings are also gaining traction due to their strong barrier properties and compatibility with various can designs.

By Application

- Food Cans:

Food cans remain the largest application category and are expected to hold close to one-third of the market by 2034. Increased consumption of ready-to-eat meals, canned vegetables, soups, and processed foods continues to stimulate demand.

- Beverage Cans:

The beverage industry—particularly carbonated soft drinks, energy drinks, and ready-to-drink beverages—drives substantial demand for interior and exterior can coatings. The global shift toward aluminum beverage cans for sustainability further supports this trend.

- Aerosol & General-Line Cans:

Aerosol-based household, personal-care, and automotive products require specialized coatings that offer chemical resistance and durability. This segment continues to grow as consumer demand for spray-based products expands.

To access the complete data tables and in-depth insights, request a Discount On The Report here: https://www.factmr.com/connectus/sample?flag=S&rep_id=7522

Primary Growth Drivers

1. Rising Consumption of Packaged Food & Beverages

Changing lifestyles, rapid urbanization, and increased reliance on convenient food options are fueling demand for metal cans. As packaged food and beverages remain central to global consumption patterns, high-performance can coatings are essential for product freshness, safety, and shelf-life.

2. Strong Push for Food-Safe, BPA-Free Coatings

Regulatory authorities worldwide are imposing stricter measures on food-contact materials. This has accelerated the shift toward safer, BPA-free, and environmentally friendly coatings, particularly acrylic and water-based formulations. Manufacturers are actively reformulating products to comply with evolving safety standards.

3. Sustainability & High Recyclability of Metal Cans

Metal cans are among the most recyclable forms of packaging. As sustainability becomes a top priority for brands and consumers, the demand for recyclable packaging with compatible coatings is rising. Coatings that maintain performance through multiple recycling cycles are becoming increasingly important.

4. Technological Advancements in Coating Materials

Innovations such as improved corrosion resistance, thinner coating layers, enhanced chemical stability, and faster-curing formulations are allowing manufacturers to achieve better performance while reducing material usage and production costs.

Challenges Impacting Market Growth

- Raw Material Volatility:

Price fluctuations in resin feedstocks impact production costs for coating manufacturers.

- Regulatory Pressure on Chemical Composition:

With increasing food-safety regulations, manufacturers must invest heavily in R&D to ensure compliance, adding cost and complexity.

- High Performance Requirements:

Each can type—whether for acidic foods, carbonated beverages, or chemical aerosols—demands specific coating characteristics. Developing versatile, cost-effective coatings remains a technical challenge.

Regional Insights

- North America:

A mature but steady-growth market with high consumption of canned beverages and packaged foods. Strong regulatory frameworks drive continuous innovation in coating formulations.

- Europe:

Strict sustainability and food-safety standards contribute to rapid adoption of BPA-free, eco-friendly coatings. Demand for aluminum beverage cans also supports growth.

- Asia-Pacific:

The fastest-growing region due to booming food & beverage industries, expanding middle-class populations, and increased production of aerosol consumer products. Countries with rising urbanization are major contributors to market expansion.

- Latin America & Middle East/Africa:

Growth is supported by increasing packaged food consumption, modernization of packaging industries, and rising local manufacturing capacities.

Competitive Landscape

Leading companies in the market are focusing on:

- Developing advanced, non-toxic, and sustainable coating solutions

- Expanding product portfolios to meet diverse can performance needs

- Investing in R&D to stay ahead of regulatory changes

- Strengthening supply chains to ensure consistent raw material availability

- Collaborating with food, beverage, and packaging manufacturers to deliver integrated coating solutions

These strategies are enabling companies to secure long-term partnerships and increase market penetration across global markets.

Market Outlook to 2034

The Can Coatings Market is expected to continue its steady upward trend, reaching an estimated USD 3.61 billion by 2034. Growth will be driven by rising demand for safe, sustainable, and high-performance packaging solutions across food, beverage, aerosol, and general-line can applications.

Manufacturers that embrace innovation, sustainability, and compliance with evolving food-contact regulations will be best positioned to capitalize on the market’s long-term opportunities.

Browse Full Report: https://www.factmr.com/report/can-coatings-market