Biaxially Oriented Polypropylene (BOPP) films have become an integral part of the modern packaging industry. Renowned for their clarity, strength, and versatility, these films offer significant advantages over traditional packaging materials. BOPP films are extensively used in applications such as bags, pouches, labels, tapes, and wraps across various sectors, including food and beverages, pharmaceuticals, personal care, and consumer goods. The growing demand for lightweight, durable, and visually appealing packaging is driving the adoption of BOPP films worldwide.

Market Overview:

The BOPP films market is experiencing consistent growth due to its superior material properties and wide range of applications. These films provide excellent barrier properties against moisture, oxygen, and other environmental factors, extending product shelf life. Additionally, BOPP films offer high-quality printability, making them ideal for branding and marketing purposes. Their compatibility with heat sealing and laminating processes allows packaging manufacturers to produce efficient and aesthetically pleasing solutions.

Types of BOPP Films:

BOPP films are classified into several types based on their application. Bags and pouches dominate the market, providing flexible packaging solutions for food and consumer products. Wraps are another prominent segment, commonly used for confectionery and overwrap applications due to their transparency and optical clarity. Labels and tapes also represent significant market segments, supporting branding, safety, and promotional requirements. Each type of BOPP film is engineered to meet specific performance criteria, such as barrier resistance, durability, and print quality.

Thickness and Production Process:

BOPP films are available in various thicknesses, catering to diverse packaging needs. Films in the 15–30 microns range are the most widely used, balancing cost-efficiency with robust performance. Thicker films provide enhanced strength and protection, while ultra-thin variants support lightweight packaging and sustainable material usage. The production of BOPP films involves tenter and tubular processes, both of which ensure uniform stretching and orientation, improving mechanical strength and clarity. Advanced coating and metallization techniques further enhance barrier properties and aesthetics.

Applications and End-Use Industries:

Food packaging remains the largest end-use sector for BOPP films, particularly for snacks, confectionery, and fresh produce. These films protect products from moisture and contamination while maintaining freshness. The beverage and tobacco industries also rely on BOPP films for labeling, packaging, and decorative wraps. Personal care and pharmaceutical products benefit from the high barrier properties and printability, which are crucial for branding and regulatory compliance. The electrical and electronics sector uses BOPP films for insulation, protective wrapping, and component packaging. Overall, BOPP films’ versatility enables widespread adoption across industries requiring durable, lightweight, and visually appealing packaging solutions.

Regional Insights:

Asia Pacific holds a leading position in the BOPP films market, driven by robust manufacturing infrastructure and growing consumer goods production in countries like China and India. North America follows closely, supported by stringent food safety regulations and expanding e-commerce packaging needs. Europe emphasizes premium packaging applications, particularly in pharmaceuticals and high-quality consumer products. Emerging markets are witnessing steady growth due to increasing urbanization, rising disposable incomes, and demand for branded packaged goods. Regional market dynamics reflect both production capabilities and consumption patterns, influencing overall market growth.

Key Market Drivers:

Several factors are fueling the growth of the BOPP films market:

- Rising Demand for Flexible Packaging:The global shift from rigid packaging to lightweight, flexible alternatives is driving BOPP film adoption. Packaging converters and brand owners prefer films that provide protection without adding bulk.

- E-Commerce Expansion:The rapid growth of online retail has created a need for durable packaging solutions capable of withstanding shipping stresses. BOPP films offer puncture resistance, tamper-evidence, and aesthetic appeal, making them suitable for e-commerce applications.

- Food Safety and Shelf-Life Extension:Increasing consumer awareness and regulatory requirements for food safety encourage the use of BOPP films with superior barrier properties. These films help extend product shelf life while maintaining quality.

- Sustainability Initiatives:BOPP films are being developed with recyclable and compostable options, addressing environmental concerns. Sustainable packaging trends are influencing product innovation and market demand.

Challenges and Restraints:

Despite strong growth, the BOPP films market faces challenges. Volatile raw material prices can impact profit margins, while competition from alternative packaging materials like biodegradable plastics and paper-based films may limit market expansion. Recycling multi-layer BOPP films poses environmental and logistical challenges, particularly in regions with advanced waste management infrastructure. Companies must balance performance, cost, and sustainability to maintain competitive advantage.

Emerging Trends:

- High-Barrier Coatings:Manufacturers are investing in films with improved oxygen and moisture barriers, catering to sensitive food and pharmaceutical products.

- Digital Printing Integration:Advanced printing technologies allow for high-resolution graphics on BOPP films, enhancing brand visibility and consumer engagement.

- Ultra-Thin and Lightweight Films:Innovations in thin-gauge BOPP films support lightweight packaging initiatives without compromising strength or durability.

- Circular Economy Practices:Companies are focusing on recyclable and compostable films, promoting sustainable packaging solutions aligned with eco-conscious consumer preferences.

Competitive Landscape:

The BOPP films market exhibits moderate concentration, with major players competing through advanced product portfolios and manufacturing capabilities. Key market participants include Cosmo Films Limited, Taghleef Industries, CCL Industries, Jindal Poly Films, Sibur Holdings, Zhejiang Kinlead Innovative Materials, Inteplast Group, Poligal S.A., Uflex Ltd., and Polinas. Companies are investing in research and development to enhance product performance, expand production capacities, and address sustainability challenges. Strategic collaborations between manufacturers and brand owners are also shaping market growth and innovation.

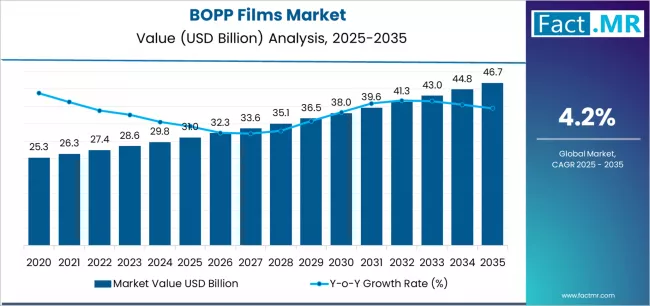

Future Outlook:

The BOPP films market is poised for sustained growth in the coming decade. Increasing demand for flexible, lightweight, and high-performance packaging across food, pharmaceutical, and consumer goods sectors will continue to drive adoption. Advances in coating, metallization, and digital printing technologies are expected to expand product applications. Sustainability and regulatory compliance will remain crucial factors influencing market trends. Manufacturers focusing on innovation, operational efficiency, and circular economy integration will gain a competitive edge in the evolving landscape.

Conclusion:

BOPP films represent a cornerstone of modern packaging solutions, providing versatile, durable, and visually appealing materials for a wide range of industries. Their unique combination of barrier properties, printability, and compatibility with heat-sealing and laminating processes makes them indispensable in flexible packaging. With strong growth drivers, emerging trends, and technological advancements, the BOPP films market is well-positioned to meet evolving consumer and industrial needs. Companies investing in product innovation, sustainable practices, and strategic collaborations are likely to thrive, shaping the future of flexible packaging globally.

Key Takeaways:

- BOPP films offer superior clarity, strength, and printability, supporting diverse packaging applications.

- Bags and pouches dominate the market, while wraps, tapes, and labels contribute significantly to adoption.

- Asia Pacific leads production and consumption, followed by North America and Europe.

- Market growth is driven by e-commerce, food safety needs, and sustainability initiatives.

- Challenges include raw material volatility, recycling complexities, and competition from alternative materials.

- Innovation in high-barrier, ultra-thin, and digitally printable films is shaping future market trends.

Browse Full Report – https://www.factmr.com/report/bopp-films-market