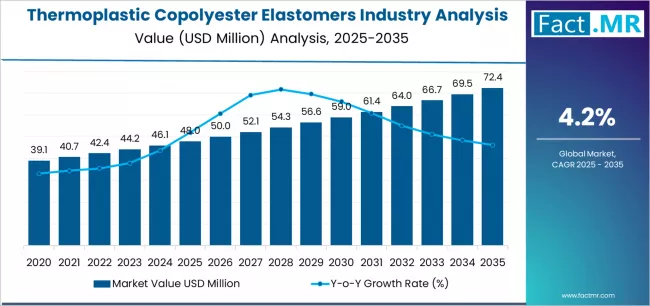

The Middle East and Africa (MEA) thermoplastic copolyester elastomers market is gearing up for steady expansion over the next ten years, supported by growing automotive production, industrial diversification, infrastructure investment, and increasing need for flexible, durable, and high-performance polymer materials. According to the latest insight from Fact.MR, regional demand for thermoplastic copolyester elastomers is projected to grow from USD 48 million in 2025 to around USD 72 million by 2035, reflecting an absolute increase of USD 24 million over the forecast period. This marks 50.0% total market growth, with demand rising at a CAGR of 4.2% from 2025 to 2035.

The shift toward recyclable engineering polymers with high flexibility, chemical resistance, temperature stabilityPE stability, and mechanical performance is accelerating adoption of TPE-E across multiple end-use sectors throughout MEA.

Browse Full Report: https://www.factmr.com/report/middle-east-and-africa-thermoplastic-copolyester-elastomers-industry-analysis

Key Market Growth Drivers

Automotive Sector Strengthens Elastomer Uptake

TPE-E is gaining traction in automotive applications due to its:

• High heat and oil resistance

• Superior flexural endurance

• Lightweight performance

• Recyclability compared to conventional rubber

Its use in air duct systems, fluid-handling tubes, cable jacketing, and exterior and interior flexible components is expanding rapidly. The MEA region’s rising EV-ecosystem development and continued investments in automotive manufacturing hubs are further fueling elastomer demand.

Industrial & Infrastructure Growth Creates High-Performance Polymer Applications

MEA governments are actively pushing economic diversification, manufacturing self-reliance, and megaproject infrastructure development. This has increased demand for TPE-E in:

• Industrial hoses and tubing

• Electrical insulation and cable sheathing

• Seals, gaskets, and mechanical parts

• Flexible joints and construction components

Growth in oil & gas extraction, logistics infrastructure, and machinery manufacturing continues to support polymer market penetration.

Demand for Sustainable and Durable Material Solutions

With sustainability becoming a market mandate, manufacturers are shifting toward engineering elastomers that offer:

• Long service life

• Enhanced chemical and weather durability

• Recyclability and reduced carbon footprint

This transition is particularly strong in industrial manufacturing and electrical applications.

Technological Advancements in Polymer Engineering

Improvements in compounding technologies, performance-tuning of copolyester formulations, colorability options, and integration with precision molding and extrusion techniques are widening TPE-E usage across regional industries.

Regional Market Highlights

Middle East: Industrial Material Innovation and Energy-Sector Demand

GCC countries are witnessing steady growth due to:

• Expansion of oil & gas tubing requirements

• Growth of industrial manufacturing clusters

• Investment in electrical infrastructure for smart grids and utilities

Africa: Rising Demand in Electrical, Automotive, and Consumer-Driven Industrial Materials

African markets are gaining momentum through:

• Increased automotive production initiatives

• Development of durable cable-sheathing solutions

• Expanding industrial polymers sector serving flexible product applications

Market Segmentation Overview

By Processing Method

- Extrusion – Lead segment due to demand in cables, tubes, and hoses

• Injection Molding – Growth driven by automotive and industrial components

• Blow Molding – Increasing use in fluid-handling applications

By Application

- Automotive Components – Fastest-growing segment

• Industrial Hoses & Tubing – Strong and sustained demand

• Electrical & Cable Sheathing – Key high-volume application segment

• Consumer & Engineering Flexible Products – Gradual rise across MEA

Challenges Influencing Adoption

- Cost Sensitivity: Higher pricing compared to standard rubber and lower-end elastomers

- Raw Material Supply Stability: Regional dependence on imported polymer feedstock

- Processing Expertise Requirements: Need for advanced extrusion and molding know-how

Competitive Landscape

The MEA TPE-E market includes both global polymer producers and compound manufacturers focused on:

• Customized COPE formulations

• Heat-resistant and chemical-tuned product lines

• Expansion through regional distributors and manufacturing partnerships

Major companies are prioritizing:

• Sustainable polymer innovations

• Enhanced compound flexibility without compromising durability

• Co-development of automotive and industrial material solutions

Recent Industry Trends

- Advanced copolyester elastomer grades introduced for high-temperature industrial tubing

• Growth in TPE-E cable-sheathing solutions to support energy and utilities infrastructure

• Automotive manufacturers increasing use of recyclable elastomers for flexible components

Future Outlook: Resilient Growth through High-Performance Polymer Integration

The next decade will continue to see rising use of thermoplastic copolyester elastomers, backed by:

• Automotive industry expansion

• Strong industrial polymer requirements

• Electrical infrastructure development

• Demand for durable and recyclable elastomers