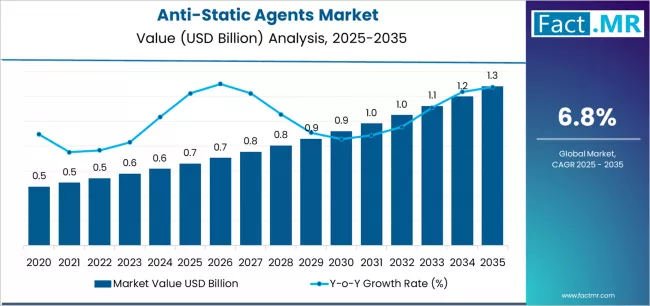

The global anti-static agents market is set for robust expansion over the next decade, driven by rising demand for static control solutions across plastics, electronics, packaging, and automotive applications. According to a new analysis by Fact.MR, the market is projected to grow from USD 0.66 billion in 2025 to USD 1.28 billion by 2035, reflecting a strong CAGR of 6.8% and an absolute increase of USD 0.62 billion during the assessment period.

As industries increasingly adopt high-speed manufacturing, advanced polymers, and sensitive electronic components, the need for reliable static-dissipating additives is accelerating. Anti-static agents—used in films, packaging materials, textiles, consumer electronics, automotive interiors, and industrial equipment—are playing a vital role in preventing dust attraction, material sticking, and electrostatic discharge (ESD) risks.

Strategic Market Drivers

Booming Plastics Processing & Packaging Industries

The rise of flexible packaging, high-performance polymer films, and multilayer structures is fueling significant use of anti-static agents. These additives minimize surface resistivity, improve processing efficiency, and enhance safety in polyethylene (PE), polypropylene (PP), and PVC applications. The growth of food & beverage packaging, e-commerce shipments, and pharmaceutical pouches is further reinforcing demand.

Growing Electronics & Semiconductor Manufacturing

With rapid digitalization and high global demand for consumer electronics, semiconductors, and circuit boards, anti-static agents are essential in preventing component damage from ESD. The expansion of EV electronics, smart devices, and advanced chip manufacturing in East Asia and the U.S. is acting as a major catalyst.

Regulatory Push Toward Safety & Material Handling Standards

Stricter guidelines on workplace safety, dust explosion prevention, and electrostatic discharge management are encouraging industries to adopt specialty anti-static additives. Industries such as chemicals, pharmaceuticals, and packaging logistics increasingly require antistatic surfaces to minimize operational hazards.

Advances in Bio-Based & Sustainable Additives

Manufacturers are shifting toward natural fatty acid–based, biodegradable, and non-toxic anti-static agents to align with sustainability goals and regulatory compliance. Innovations in internal and external anti-static formulations are enhancing compatibility, long-term performance, and environmental safety.

Browse Full Report: https://www.factmr.com/report/anti-static-agents-market

Regional Growth Highlights

North America: Strong Demand from Packaging & Electronics

Growth is supported by expanding e-commerce packaging, electronics manufacturing, and automotive lightweighting initiatives. The U.S. continues to lead adoption due to a mature plastics industry and increasing integration of antistatic solutions in consumer goods.

Europe: Sustainability and High-Performance Materials

Europe’s sustainability-driven regulations are fostering the adoption of bio-based and REACH-compliant anti-static additives. Germany, France, the U.K., and Italy show strong demand in high-value electronics, engineered plastics, and premium packaging.

East Asia: The Global Manufacturing Powerhouse

China, Japan, and South Korea dominate consumption due to their extensive plastics production capacities, booming electronics industries, and advanced semiconductor sectors. Rapid technological upgrades continue to stimulate market growth.

Emerging Markets: Packaging & Industrial Growth Opportunities

India, Southeast Asia, Brazil, and the Middle East are witnessing fast growth driven by expanding plastics consumption, industrialization, and modern packaging infrastructure.

Market Segmentation Insights

By Product Type

- Glycerol Esters & Fatty Acid Esters – Widely used due to compatibility with polyolefins.

- Ethoxylated Amines – Popular in industrial applications.

- Quaternary Ammonium Compounds – Preferred for strong surface activity.

- Others (Metallic Salts, Amides, etc.) – Niche but growing applications.

By Application

- Plastics & Polymers – Largest segment, used in films, packaging, and injection molding.

- Electronics & Semiconductors – Critical for protecting sensitive components.

- Textiles – Used in fibers, carpets, and apparel to reduce static cling.

- Automotive – Increasing use in interior components and lightweight composites.

- Industrial Equipment & Manufacturing – For safe handling and dust prevention.

By Form

- Internal Anti-Static Agents – Incorporated during polymer processing.

- External Anti-Static Agents – Surface-applied coatings and treatments.

Challenges Impacting Market Growth

- Fluctuating Raw Material Prices – Affecting cost of fatty acids, amines, and petrochemical intermediates.

- Compatibility Issues with Certain Polymers – Need for formulation customization.

- Short-Term Efficacy of Some Agents – Drives demand for long-lasting alternatives.

- Competition from Anti-ESD Coatings & Conductive Materials – Expanding static control alternatives.

Competitive Landscape

The anti-static agents market is moderately competitive, with companies focusing on sustainability, polymer compatibility, and advanced formulations.

Key Companies Profiled

- Clariant

- BASF SE

- Croda International

- A. Schulman

- Arkema S.A.

- DuPont

- Evonik Industries

- Nouryon

- Fine Organics

- Ampacet Corporation

Manufacturers are investing in long-lasting anti-static technologies, bio-based solutions, and high-performance additives tailored for fast-manufacturing environments.

Recent Developments

- 2024: Launch of sustainable, plant-derived anti-static additives for packaging films.

- 2023: Rising adoption of high-performance anti-static agents in semiconductor and EV battery manufacturing.

- 2022: Introduction of long-lasting internal anti-static additives for premium polyolefin films in Europe.

Future Outlook: A Decade of Safe, Sustainable, and High-Performance Material Advancements

From smart electronics to modern packaging and automated manufacturing, the global anti-static agents market is poised for continued expansion through 2035. Increasing focus on safety, sustainability, and performance will drive innovation in bio-based formulations, long-term ESD protection, and polymer compatibility.

With rising adoption across plastics, electronics, automotive, and industrial sectors, anti-static agents will remain indispensable in ensuring operational efficiency, product protection, and regulatory compliance worldwide.