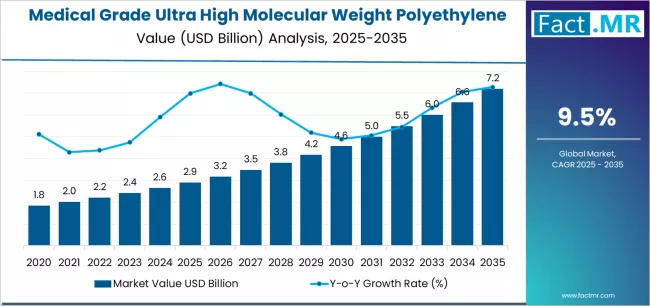

The global medical grade ultra high molecular weight polyethylene (UHMWPE) monomer market is poised for significant expansion, driven by rising utilization of high-strength, wear-resistant polymers across orthopedic implants, surgical tools, and trauma management solutions. According to a recent analysis, the market is expected to grow from USD 2.9 billion in 2025 to USD 7.2 billion by 2035, reflecting an impressive absolute increase of USD 4.3 billion and a strong CAGR of 9.5% during the forecast period.

UHMWPE, known for its exceptional durability, biocompatibility, and resistance to abrasion, has become a critical material for advanced medical applications—particularly in joint replacement, prosthetics, and minimally invasive surgical procedures.

Key Market Drivers

Growing Demand for High-Durability Medical Implants

Rising incidences of osteoarthritis, rheumatoid arthritis, and joint degeneration are supporting a surge in hip and knee replacement surgeries worldwide. Medical-grade UHMWPE monomers—used to manufacture liners, bearings, and articulating surfaces—offer unmatched wear resistance, making them essential for long-lasting orthopedic implants. Enhanced crosslinking technologies are enabling manufacturers to extend the lifecycle and performance of implant components.

Rising Adoption in Minimally Invasive and Laparoscopic Procedures

Insights from the Laparoscopic Gynecological Procedures Market show rapid adoption of minimally invasive surgical (MIS) technologies globally. UHMWPE is widely used in surgical instrument components, trocar tips, articulating arms, and device housings due to its sterilization resistance and non-reactive properties. As laparoscopic procedures continue to rise—driven by reduced recovery times and growing patient preference—the demand for UHMWPE-based medical device components is expanding steadily.

Surging Need for Biocompatible and High-Performance Polymers

Medical device manufacturers increasingly seek materials that combine strength, stability, and biocompatibility. UHMWPE offers:

- Low friction coefficient

- High impact strength

- Chemical and moisture resistance

- Superior fatigue resistance

These characteristics make it ideal for next-generation prosthetics, orthopedic bearings, and trauma fixation systems.

R&D in Advanced Polymer Engineering

Major players are investing in next-generation UHMWPE technologies—such as highly cross-linked materials, vitamin E-stabilized variants, and antimicrobial polymer composites—to improve longevity and clinical outcomes. Such advancements are significantly increasing UHMWPE’s appeal within premium implant product lines.

Browse Full Report: https://www.factmr.com/report/medical-grade-ultra-high-molecular-weight-polyethylene-uhmwpe-monomer-market

Regional Growth Highlights

North America: Leading with Strong Orthopedic Procedure Volumes

The U.S. remains the world’s largest market for joint replacement surgeries, driven by an aging population, high obesity prevalence, and widespread access to advanced orthopedic care. Strong presence of implant manufacturers and high adoption of MIS devices funnel strong demand for medical-grade UHMWPE monomers.

Europe: Demand Driven by Aging Population and Technological Upgrades

Germany, the U.K., France, and Italy are key contributors as European healthcare facilities increasingly adopt advanced polymer-based implants. Stringent quality regulations and emphasis on long-term implant performance support UHMWPE penetration in orthopedic and trauma applications.

Asia-Pacific: Fastest-Growing Market

Rapid healthcare infrastructure development, rising medical tourism, and increasing awareness regarding high-quality implant materials are accelerating UHMWPE adoption in China, India, Japan, and South Korea. Expanding investment in local manufacturing also supports regional growth.

Latin America & Middle East: Growing Demand for Affordable Implant Solutions

Countries like Brazil, Mexico, the UAE, and Saudi Arabia are witnessing increasing healthcare modernization. Demand for cost-effective, durable orthopedic and surgical devices is creating new opportunities for UHMWPE monomer manufacturers.

Market Segmentation Insights

By Form

- Highly Cross-Linked UHMWPE — Preferred in modern orthopedic implants due to enhanced wear resistance.

- Non-Cross-Linked UHMWPE — Used in conventional implants and general medical components.

- Vitamin E-Stabilized UHMWPE — Gaining traction for oxidative stability and extended implant lifespan.

By Application

- Orthopedic Implants (hip, knee, shoulder, and spine components)

- Surgical Instruments & Devices (laparoscopic tools, endoscopic equipment)

- Prosthetics & Orthotics

- Trauma & Fixation Devices

- Medical Robotics Components

Market Challenges

Despite its promising outlook, the UHMWPE monomer market encounters notable challenges:

- High Production Costs: Advanced crosslinking and stabilization processes raise material costs.

- Regulatory and Compliance Pressure: Stringent approval processes for implant materials can extend product development cycles.

- Competition from Alternative Polymers: PEEK and bioresorbable polymers present competitive options in select surgical categories.

- Supply Chain Complexity: Sourcing of medical-grade monomers and purification systems requires strict quality control and certification.

Competitive Landscape

The market is moderately consolidated, with major players focusing on product innovation, new material formulations, and strategic partnerships with implant manufacturers. Companies are also investing in sustainable, energy-efficient production processes to meet regulatory and environmental standards.

Leading Companies Include:

- Celanese Corporation

- Mitsubishi Chemical Advanced Materials

- Quadrant EPP

- Orthoplastics Ltd.

- DSM Biomedical

- Ticona Engineering Polymers

- Zhejiang Wanma Macromolecule

These organizations are driving advancements in high-performance UHMWPE grades tailored for orthopedic, surgical, and trauma care applications.

Future Outlook: Advancing Precision Healthcare Through High-Performance Polymers

Over the next decade, medical-grade UHMWPE monomers will play a central role in enhancing the durability, safety, and performance of medical implants and devices. As global demand for minimally invasive surgeries and high-quality joint replacements continues to rise, UHMWPE will remain the preferred polymer for long-term, high-stress medical applications.

Manufacturers that leverage innovations in material crosslinking, antioxidant stabilization, and biocompatible engineering—while expanding collaboration with orthopedic and surgical device companies—are poised for accelerated growth in the coming years.

The market’s trajectory points toward enhanced material efficiency, improved patient outcomes, and transformative advancements in global medical device manufacturing.