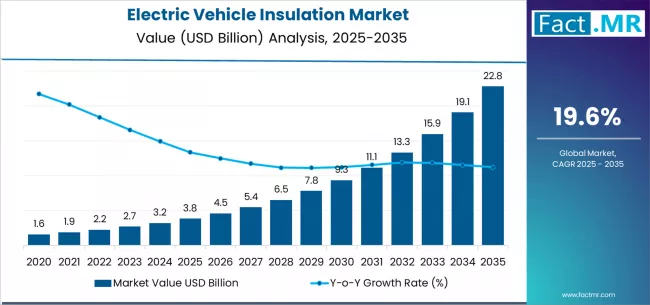

The global electric vehicle insulation market is set for extraordinary expansion, driven by rapid vehicle electrification, heightened safety standards, and the global shift toward high-efficiency energy systems. According to a recent Fact.MR analysis, the market is expected to grow from USD 3.8 billion in 2025 to USD 22.8 billion by 2035, recording an impressive absolute increase of USD 19.0 billion. This indicates a powerful 500% total expansion, advancing at a remarkable CAGR of 19.6% throughout the forecast period.

As EV adoption accelerates worldwide, insulation materials are becoming integral to optimizing battery performance, enhancing passenger safety, and ensuring thermal stability in next-generation electric mobility.

Key Market Drivers

Rapid EV Adoption and Increasing Thermal Management Needs

With global EV sales surging, the need for advanced insulating materials—such as foams, aerogels, and thermal interface products—continues to intensify. As EV batteries generate significant heat, manufacturers rely on high-performance insulation to ensure thermal uniformity, prevent overheating, and maximize battery lifespan. Regulatory pressure for safer, fire-resistant systems is further elevating demand for certified insulation materials.

Shift Toward Lightweight and High-Efficiency Components

Automakers are aggressively replacing metal components with lightweight, high-strength insulation materials to reduce vehicle weight and extend driving range. Materials like elastomers, ceramics, fiberglass, and high-performance polymers are enabling superior energy efficiency while maintaining structural integrity and safety.

Advancements in Battery & Power Electronics Safety

EV batteries, inverters, converters, and onboard chargers require robust insulation to prevent electrical failures and thermal runaway. As battery capacity increases and charge speeds accelerate, the need for durable, high-temperature-resistant insulation continues to rise, particularly in solid-state and high-voltage EV platforms.

Browse Full Report: https://www.factmr.com/report/electric-vehicle-insulation-market

Regional Growth Highlights

North America: Strong Regulatory Push and OEM Expansion

The U.S. and Canada are experiencing fast adoption of electric vehicles driven by incentives, infrastructure development, and major EV manufacturing investments. With growing production of lithium-ion and next-gen battery systems, the demand for thermal and electrical insulation is surging across the region.

Europe: Sustainability Leadership and Advanced EV Ecosystems

Europe remains a dominant hub for EV innovation, supported by ambitious climate targets, carbon-neutrality goals, and strict safety norms. High demand for premium EVs and the expansion of battery gigafactories are fueling significant growth in insulation materials for thermal, acoustic, and electrical applications.

Asia-Pacific: Largest Production Hub for Batteries & EVs

China, Japan, and South Korea continue to lead global EV manufacturing, with massive investments in EV infrastructure and battery production. Asia-Pacific’s cost-efficient production capabilities and rapid technological advancements make it the largest and fastest-evolving EV insulation market.

Latin America & Middle East: Emerging Adoption with Strong Potential

As EV imports rise and governments pursue sustainable transportation policies, adoption of insulation materials in these regions is gaining momentum, particularly in premium EV segments.

Market Segmentation Insights

By Material Type

- Foam Insulation – Widely used in battery packs and vehicle interiors due to its flexibility and lightweight properties.

- Aerogel Insulation – High-performance and premium, ideal for thermal hotspots in EV systems.

- Fiberglass and Mineral Wool – Strong fire resistance for critical components.

- Ceramic & Polymer-Based Insulation – Increasingly adopted for high-temperature and high-voltage applications.

By Application

- Battery Pack & Module Insulation – Largest segment driven by rising thermal protection needs.

- Power Electronics Insulation – Essential for converters, inverters, and chargers.

- Interior Acoustic & Thermal Insulation – Enhancing cabin comfort by reducing motor noise.

- Underbody and Thermal Barrier Panels – Protecting structural components and passengers from heat exposure.

By Vehicle Type

- BEVs (Battery Electric Vehicles) – Dominant segment due to higher need for insulation in batteries.

- PHEVs (Plug-In Hybrid Electric Vehicles) – Steady adoption across global markets.

- FCEVs (Fuel Cell Electric Vehicles) – Emerging segment requiring advanced thermal barriers.

Market Challenges

Despite strong potential, several challenges may impact market momentum:

- High Cost of Advanced Insulation Materials – Aerogels, ceramics, and specialty polymers remain expensive for mass adoption.

- Thermal Runaway Risks – Insufficient insulation could lead to safety issues, requiring continuous innovation.

- Complex Manufacturing Requirements – Integrating insulation in high-voltage and fast-charging EVs demands precision engineering.

- Recycling and Sustainability Concerns – Insulation materials must evolve to meet circular-economy targets.

Competitive Landscape

The electric vehicle insulation market is moderately consolidated, with companies focusing on material innovation, fire-resistant technologies, and strategic partnerships with automotive OEMs and battery manufacturers. Leading players are expanding R&D capabilities, enhancing thermal conductivity solutions, and rolling out specialized insulation for solid-state batteries and ultra-fast charging systems.

Prominent Companies Include:

- 3M Company

- BASF SE

- Saint-Gobain

- Rogers Corporation

- ZF Friedrichshafen AG

- Covestro AG

- DuPont

- Palmetto Industries

These firms are pioneering lightweight materials, advanced thermal barriers, and next-generation insulation tailored for high-performance EV designs.

Future Outlook: Advancing the Next Era of High-Performance Electric Mobility

The next decade will reshape the electric mobility landscape, with insulation materials playing an increasingly central role in enhancing EV performance, safety, and efficiency. As automakers transition to higher-voltage architectures, solid-state batteries, and ultra-fast charging systems, demand for innovative insulation solutions will multiply rapidly.

Manufacturers that invest in material innovation, sustainable production, and close collaboration with OEMs will be at the forefront of this industry transformation. With global EV targets accelerating and safety regulations tightening, the electric vehicle insulation market stands poised for unprecedented growth and technological evolution.