The automotive front-end module market is undergoing a transformative phase as vehicle manufacturers increasingly adopt modular designs and lightweight materials to improve performance, safety, and fuel efficiency. Front-end modules (FEMs) have become integral components in modern vehicles, serving not only as structural elements but also as carriers for essential systems such as lighting, electronics, bumper beams, air management, and crash-support structures. The rising focus on vehicle aerodynamics, sustainability, and production flexibility continues to drive demand for advanced front-end module solutions.

As automotive production grows more sophisticated—particularly with the rise of electric vehicles (EVs) and hybrid models—the role of front-end modules is expanding. Manufacturers are integrating more electronic, thermal, and safety components within the FEM framework, reflecting the market’s shift toward smart, lightweight, and highly adaptable designs.

Market Overview

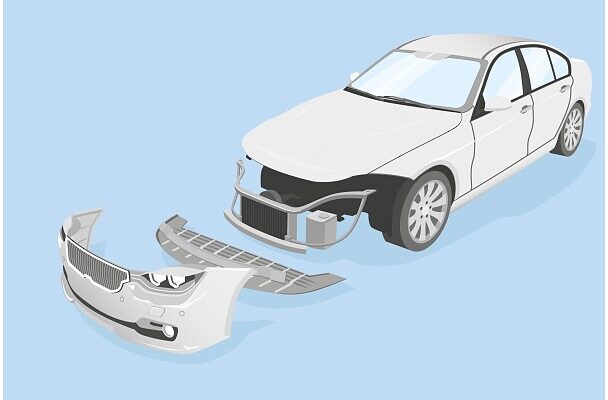

Automotive front-end modules are pre-assembled components that combine multiple structural, electronic, and mechanical parts into a cohesive unit mounted at the front of the vehicle. These modules simplify vehicle assembly, reduce manufacturing time, and optimize production efficiency.

Typical components included in an automotive FEM:

- Bumpers

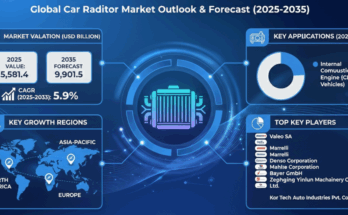

- Radiators

- Cooling fans

- Headlamps

- Air conditioning condensers

- Crash management systems

- Grilles and air ducts

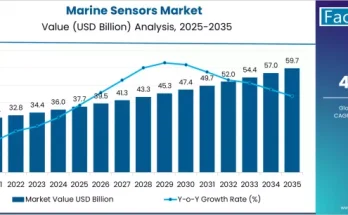

- Sensors and electronic control systems

The move toward modularity enables OEMs to standardize platforms across vehicle models, streamline supply chains, and increase design flexibility. Additionally, advancements in materials—such as thermoplastics, composites, and lightweight alloys—have significantly improved the performance and durability of front-end modules while reducing overall vehicle weight.

Regional Insights

North America

North America remains a key market for front-end module innovation due to strong automotive manufacturing capabilities and the presence of leading OEMs and suppliers. The region’s push toward electrification and the adoption of advanced driver-assistance systems (ADAS) encourages manufacturers to incorporate more sensors, cameras, and thermal management components into FEM structures.

Europe

Europe is at the forefront of lightweight material adoption and sustainable vehicle manufacturing. Stringent environmental regulations and the region’s robust EV expansion are fueling demand for modular, lightweight FEMs with enhanced energy absorption properties. European automakers continue to prioritize eco-friendly materials and aerodynamic designs, shaping the future of front-end module engineering.

Asia-Pacific

Asia-Pacific dominates global automotive production and is rapidly expanding its technological capabilities in automotive components. The region’s strong manufacturing ecosystem, rising disposable income, and high vehicle production rates create widespread adoption opportunities for advanced FEM systems. With competitive manufacturing costs and rapid innovation, Asia-Pacific serves as a major hub for FEM suppliers and OEMs.

Middle East & Africa

While still emerging, the Middle East & Africa region presents steady demand for automotive front-end modules driven by increasing vehicle imports, expanding assembly plants, and growth in commercial vehicle use. Rising investments in road infrastructure and logistics contribute to the region’s long-term automotive component market potential.

Key Trends & Forecast

Shift Toward Lightweight and Sustainable Materials

Automotive manufacturers are increasingly adopting lightweight materials such as reinforced plastics, composites, and aluminum to reduce vehicle weight and enhance fuel economy. These materials improve crash performance, durability, and design flexibility, making them ideal for modern FEM applications.

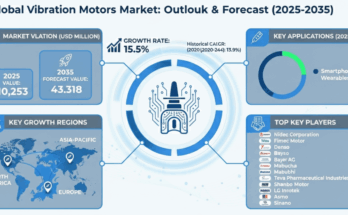

Increasing Integration of Electronics and ADAS Components

Front-end modules are becoming critical hubs for sensors, radars, cameras, and other ADAS components. As vehicles move toward higher automation levels, FEM designs are evolving to support advanced connectivity and safety systems.

Rise of Electric and Hybrid Vehicles

EVs and hybrid vehicles require specialized front-end modules to accommodate thermal management systems, battery cooling units, and electronic control components. This shift is accelerating innovation in FEM structure, design, and materials.

Growing Preference for Modular and Pre-Assembled Units

OEMs favor modularity because it reduces assembly line complexities and shortens production cycles. Pre-assembled FEMs also enhance customization capabilities, allowing manufacturers to adapt quickly to model-specific requirements.

Collaboration Between OEMs and Tier-1 Suppliers

Partnerships between vehicle manufacturers and component suppliers are shaping the future of front-end module development. Joint engineering initiatives allow faster innovation cycles, improved cost efficiency, and integration of advanced technologies in FEM designs.

Applications & End-Use Outlook

Front-end modules play a pivotal role across multiple vehicle categories:

Passenger Vehicles

The passenger vehicle segment benefits from advanced FEMs with improved aesthetics, safety features, and integrated electronics. Stylish designs, increased component density, and better thermal regulation are key focus areas.

Commercial Vehicles

Commercial vehicle FEMs are designed for durability, ease of maintenance, and enhanced structural support. Modular FEMs enable faster repairs and improved reliability—critical for logistics and transportation fleets.

Electric Vehicles (EVs)

In EVs, front-end modules support key components such as electric radiators, battery cooling systems, pedestrian protection sensors, and charging-related electronics. EV manufacturers are increasingly adopting FEMs tailored to the unique architecture of electric powertrains.

Aftermarket and Replacement Demand

Accidents and wear-and-tear contribute to growing replacement demand for front-end modules and associated components. The aftermarket segment is expanding as more vehicles on the road require updated FEMs for optimal safety and performance.

Conclusion

The automotive front-end module market continues to advance as automakers seek greater efficiency, safety, and modularity in vehicle design. With increasing integration of electronics, rising adoption of lightweight materials, and the global shift toward electric mobility, FEMs are becoming more sophisticated and essential than ever before.

As industries evolve and consumer demands change, the front-end module landscape will remain a dynamic and innovative space. Manufacturers that invest in advanced designs, material innovation, and smart electronic integration will play a crucial role in shaping the next generation of automotive engineering.

Browse Full Report – https://www.factmr.com/report/29/automotive-front-end-module-market