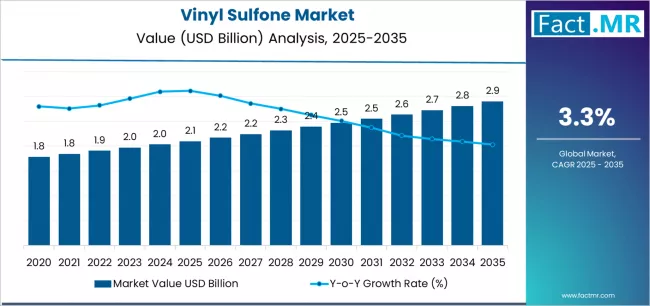

The global vinyl sulfone market is set for steady expansion over the next decade, driven by rising consumption of reactive dyes, expanding textile production, and a growing shift toward high-purity chemical intermediates. According to the latest insights from Fact.MR, the market is valued at USD 2.1 billion in 2025 and is projected to reach USD 2.9 billion by 2035, reflecting an absolute increase of USD 0.8 billion. This equates to total growth of 38.1%, with revenues rising at a CAGR of 3.3% between 2025 and 2035.

Vinyl sulfone derivatives remain essential building blocks for dye manufacturers, particularly in reactive dyes used across cotton, blended fabrics, and technical textiles. Their superior reactivity, stability, and environmentally compatible performance continue to support wide industrial adoption.

Strategic Market Drivers

Textile Industry Expansion Fuels Core Demand

Growth in apparel manufacturing, home textiles, and technical fabrics is driving consumption of vinyl sulfone-based reactive dyes. Leading textile-producing regions are investing heavily in capacity upgrades and automation, strengthening downstream demand for vinyl sulfone intermediates.

Manufacturers continue to prefer vinyl sulfone chemistry for its high fixation rate, color fastness, and compatibility with modern dyeing technologies. Emerging textile hubs in South Asia and Southeast Asia are expected to remain the largest contributors to market growth.

Rising Adoption in Specialty Chemicals

Vinyl sulfone’s performance advantages—including its efficiency as a chemical intermediate and strong electrophilic properties—are widening adoption in pharmaceutical synthesis, agrochemicals, and polymer modification. As companies shift toward high-purity intermediates and value-added formulations, vinyl sulfone producers are expanding capabilities in customized and specialty-grade production.

Sustainability and Clean Chemistry Trends

Environmental compliance is influencing product development, particularly in regions enforcing stricter wastewater and emission standards. Low-toxicity, cleaner-reacting vinyl sulfone derivatives are increasingly favored in modern dye manufacturing setups. Producers are investing in advanced synthesis routes, residue reduction, and energy-efficient manufacturing systems.

Browse Full Report: https://www.factmr.com/report/vinyl-sulfone-market

Regional Growth Highlights

East Asia: The Global Manufacturing Nucleus

East Asia continues to dominate vinyl sulfone consumption, supported by large-scale textile manufacturing and sustained investments in dye intermediates. China remains the largest producer and exporter, while South Korea and Japan contribute through high-quality specialty chemicals and R&D-led innovations.

South Asia: High-Growth Textile Powerhouse

India, Bangladesh, and Pakistan are strengthening their global textile footprint. These economies are boosting the demand for reactive dyes, driving robust uptake of vinyl sulfone derivatives. Government-led manufacturing incentives and export opportunities are amplifying growth prospects.

Europe & North America: Advancing Specialty and High-Purity Grades

Both regions are adopting vinyl sulfone derivatives in pharmaceuticals, research chemicals, and advanced materials. Stringent environmental regulations are accelerating the transition toward sustainable, low-impact intermediates and advanced dye formulations.

Middle East, Latin America & Africa: Emerging Consumption Zones

Rising apparel production, industrial development, and local textile expansions are supporting emerging demand. As countries upgrade textile processing clusters, consumption of vinyl sulfone and its derivatives is expected to increase steadily.

Market Segmentation Insights

By Application

- Reactive dye intermediates

- Pharmaceuticals and fine chemicals

- Polymer additives

- Agrochemical synthesis

By Grade

- Industrial grade

- High-purity/specialty grade

By End Use

- Textile & apparel industry

- Chemical manufacturing

- Pharmaceuticals

- Specialty applications

Challenges and Market Considerations

- Environmental Compliance: Wastewater treatment and chemical disposal regulations require continuous process optimization.

- Price Volatility: Fluctuations in raw materials such as sulfur, ethylene, and aromatics impact production costs.

- Competition from Alternate Dye Technologies: While reactive dyes dominate, growth in digital printing and dispersive dyes poses mild competition.

- Supply Chain Constraints: Logistics disruptions and geopolitical tensions can challenge raw material availability.

Competitive Landscape

The vinyl sulfone market is moderately consolidated, with companies focusing on capacity expansion, green chemistry practices, and downstream integration.

Key Players in the Vinyl Sulfone Market

- Bodal Chemicals Ltd.

- Kiri Industries Ltd.

- Shree Pushkar Chemicals and Fertilisers Ltd.

- Bhageria Industries Ltd.

- Atul Ltd.

- Sigma-Aldrich (Merck KGaA)

- VDC Group

- Hangzhou Dayangchem Co., Ltd.

- Haihang Industry Co., Ltd.

- Mayur Dye-chem Pvt. Ltd.

Leading manufacturers are strengthening R&D investments to improve process efficiency, reduce chemical residues, and develop next-generation intermediates tailored for evolving dyeing technologies.

Future Outlook: Cleaner, Faster, and More Efficient Chemistry Ahead

The next decade will reshape the vinyl sulfone market with advancements in green chemistry, process automation, and high-purity intermediate development. As global textile production continues its upward trajectory and specialty chemical demand accelerates, vinyl sulfone producers are well-positioned for stable, long-term growth.

Companies that prioritize sustainability, capacity modernization, and global supply chain integration will capture the most value—powering the next chapter of innovation in dye intermediates and chemical manufacturing.