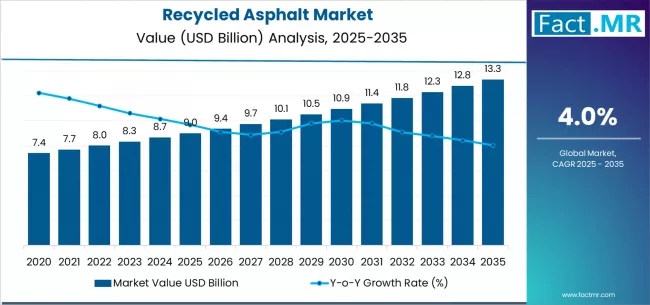

The global recycled asphalt market is on a steady growth trajectory, fueled by the increasing adoption of sustainable construction practices, rising infrastructure development, and the growing emphasis on circular economy principles. According to a recent report by Fact.MR, the market is valued at USD 9.0 billion in 2025 and is projected to reach USD 13.3 billion by 2035, reflecting a compound annual growth rate (CAGR) of 4.0% over the forecast period. This translates into an absolute increase of USD 4.5 billion, representing 50% total growth over the decade.

Strategic Market Drivers:

Rising Demand for Sustainable Construction Materials: With growing global infrastructure development, construction contractors are increasingly turning to recycled asphalt for road construction, overlays, and civil works. Recycled asphalt pavement (RAP) remains the leading product segment, capturing 62% of the market, owing to its superior performance, availability, and cost-effectiveness.

Advancements in Asphalt Recycling Technology: Hot mix recycling technology dominates the market, holding a 53% share, as it allows high-quality asphalt production for diverse construction applications. The integration of advanced recycling processes and digital monitoring systems ensures consistent quality and operational efficiency.

Infrastructure Expansion and Road Maintenance Needs: Aging road networks and increased urbanization are driving road construction and maintenance projects globally. Recycled asphalt provides a cost-effective solution that supports both environmental sustainability and long-term performance standards.

Browse Full Report: https://www.factmr.com/report/recycled-asphalt-market

Regional Growth Highlights:

North America: The U.S. and Canada are leading adopters of recycled asphalt, driven by stringent environmental regulations and large-scale road infrastructure projects. Construction companies are embracing recycled asphalt for its economic and ecological benefits, particularly in public road maintenance.

Europe: Countries like Germany, France, and the U.K. are leveraging recycled asphalt to comply with sustainability-focused regulations while advancing smart and modular infrastructure projects. Growing emphasis on circular economy strategies accelerates adoption across the continent.

Asia-Pacific: Rapid urbanization and infrastructure development in China, India, and Japan are fueling market growth. The region benefits from significant government investments in road networks and industrial facilities, creating robust demand for recycled construction materials.

Emerging Markets: Latin America, the Middle East, and South Asia are witnessing heightened interest in recycled asphalt due to expanding infrastructure projects, government development programs, and cost-efficiency considerations.

Market Segmentation Insights:

- By Product: Recycled Asphalt Pavement (RAP), Reclaimed Asphalt Shingles (RAS), Rejuvenators & Binder Modifiers. RAP leads with 62% market share.

- By Technology: Hot Mix Recycling, Cold In-Place/Plant Recycling, Surface Recycling & Foam Bitumen. Hot mix recycling dominates with 53% share.

- By End Use: Road Construction & Overlays, Driveways/Parking, Other Civil Works. Road construction & overlays segment commands 71% of applications.

Challenges and Market Considerations:

- Raw Material Supply Variability: Fluctuations in bitumen and aggregate prices can impact production costs.

- Regulatory Compliance: Increasing environmental standards necessitate adoption of cleaner, eco-friendly recycling technologies.

- Competition from Virgin Asphalt: Cost-sensitive projects may opt for conventional asphalt alternatives in certain regions.

Competitive Landscape:

The global recycled asphalt market is driven by innovation-focused competition, with key players investing in advanced recycling technologies, digital monitoring, and sustainable formulations. Leading companies include:

- CRH

- Holcim

- Vulcan Materials

- Colas

- Martin Marietta

- Heidelberg Materials

- Astec Industries

- Granite Construction

- Balfour Beatty

- Eurovia

Recent Developments:

- Companies are increasingly deploying advanced hot mix recycling plants to optimize asphalt quality and operational efficiency.

- Investments in digital monitoring systems are enabling real-time quality assurance, reducing wastage and ensuring compliance with environmental standards.

Future Outlook:

The recycled asphalt market is set for steady growth as sustainability, cost efficiency, and infrastructure modernization drive adoption. The next decade will see integration of smart recycling technologies, AI-based quality control, and enhanced material formulations. Companies that prioritize innovation, environmental compliance, and regional collaboration are poised to lead the market, delivering durable, eco-friendly, and economically viable solutions for global road construction and infrastructure projects.