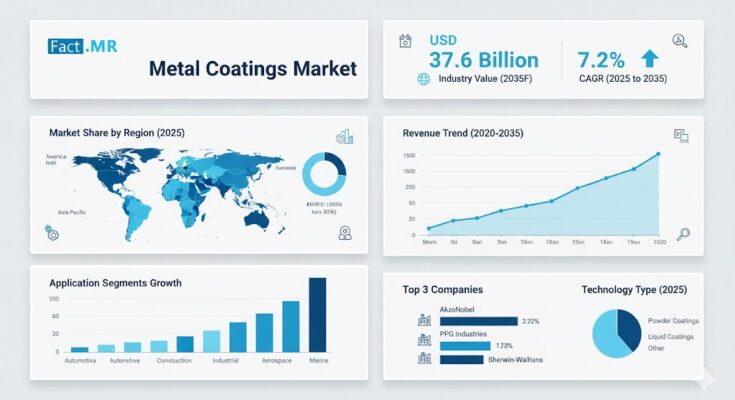

The global metal coatings market is on a robust upward trajectory as industries increasingly prioritize corrosion resistance, durability, and aesthetic enhancement across construction, automotive, and manufacturing sectors. According to a recent study by Fact.MR, the market is projected to rise from USD 18.7 billion in 2025 to USD 37.6 billion by 2035, reflecting a CAGR of 7.2% over the forecast period.

As sustainable infrastructure development and technological innovation accelerate, metal coatings are becoming indispensable for extending the lifespan of metal components, enhancing energy efficiency, and improving overall performance in challenging environments.

Strategic Market Drivers

- Growing Construction and Infrastructure Projects

The construction sector continues to be a dominant end-use industry for metal coatings. Rising investments in smart cities, residential complexes, and commercial buildings are fueling demand for coatings that offer superior weather resistance and protection against corrosion.

Architectural metal coatings are extensively used for roofing, curtain walls, and steel structures, ensuring durability and aesthetic appeal. Additionally, the shift toward energy-efficient and LEED-certified buildings is stimulating the adoption of low-VOC and eco-friendly coating formulations.

- Expanding Automotive and Transportation Industry

The automotive industry is a key growth driver, leveraging metal coatings for body panels, chassis components, and under-the-hood parts to enhance corrosion resistance, fuel efficiency, and surface aesthetics.

Lightweight aluminum components are increasingly being coated with powder and coil coatings to prevent degradation, while electric vehicle (EV) manufacturers are adopting high-performance coatings to improve heat dissipation and reduce wear on battery casings and connectors.

- Rising Demand from Industrial and Energy Sectors

In heavy machinery, oil & gas, and renewable energy applications, metal coatings play a critical role in enhancing mechanical strength and reducing maintenance costs.

Wind turbines, solar panels, and offshore platforms rely on advanced protective coatings to resist abrasion, UV degradation, and chemical exposure. The rise of renewable energy infrastructure is therefore expected to create new long-term opportunities for metal coating manufacturers.

Browse Full Report: https://www.factmr.com/report/2381/metal-coatings-market

Regional Growth Highlights

East Asia: The Manufacturing Powerhouse

East Asia dominates global demand, driven by China, Japan, and South Korea, where large-scale industrialization and infrastructural projects are accelerating consumption. The region benefits from advanced manufacturing ecosystems, strong export networks, and government incentives promoting green industrial materials.

China remains the largest producer and consumer, while Japan and South Korea are leading in technologically advanced, low-emission coating formulations.

North America: Innovation and Performance-Centric Growth

The U.S. and Canada are witnessing strong growth, supported by technological innovation and an expanding automotive and aerospace base. The demand for powder coatings and waterborne coatings is growing due to regulatory pressures and corporate sustainability goals.

Moreover, the presence of major R&D facilities and rising refurbishment of public infrastructure are propelling market expansion in the region.

Europe: Sustainability and Regulation-Driven Demand

Europe’s growth is reinforced by strict VOC emission standards and REACH regulations, which encourage the adoption of environmentally friendly and high-durability coatings. Countries like Germany, France, and the U.K. are at the forefront of material innovation, integrating nanotechnology and hybrid polymers to enhance performance.

The region’s strong automotive base and increasing renewable energy investments also contribute significantly to demand.

Emerging Markets: Infrastructure and Industrial Expansion

Regions such as South Asia, the Middle East, and Latin America are witnessing strong growth due to rapid industrialization, infrastructure development, and housing expansion. Governments are investing heavily in public utilities, transportation, and construction, creating robust opportunities for protective and decorative coating manufacturers.

Challenges and Market Considerations

Despite strong growth prospects, the metal coatings market faces several challenges:

- Raw Material Price Fluctuations: Volatility in resin and metal pigment costs affects margins.

- Environmental Compliance: Tightening VOC regulations demand continuous reformulation.

- Competition from Alternative Coatings: Ceramic and hybrid coatings offer lower maintenance and energy efficiency.

- Supply Chain Volatility: Geopolitical and logistical constraints can disrupt raw material sourcing.

Competitive Landscape

The market is characterized by intense competition and technological advancement, with key players focusing on sustainable innovations, performance enhancement, and regional expansion.

Leading Companies Profiled:

- PPG Industries, Inc.

- Akzo Nobel N.V.

- Axalta Coating Systems

- BASF SE

- Jotun A/S

- The Sherwin-Williams Company

- DowDuPont Inc.

- Kansai Paint Co., Ltd.

- Hempel A/S

- Nippon Paint Holdings Co., Ltd.

- NOF Group

- Alucoil

- United Metal Coating LLC

- Jinhu Color Powder Coating Co., Ltd.

- The Magni Group, Inc.

- Tikkurila Oyj

- Valspar Corporation (now part of Sherwin-Williams)

- RPM International Inc.

- Dow Inc.

- Sika AG

- Berger Paints India Limited

These companies are enhancing production efficiency, introducing bio-based formulations, and developing smart coatings with self-healing and anti-microbial properties.

Recent Developments

- March 2023 – Akzo Nobel launched its new Interpon D2000 Ultra range, delivering exceptional color retention and UV protection for architectural applications.

- June 2022 – PPG Industries unveiled its Envirocron High Transfer Efficiency powder coating technology to reduce waste and improve sustainability.

- November 2022 – Axalta Coating Systems introduced high-performance coatings designed for EV battery enclosures, ensuring thermal management and corrosion protection.

Future Outlook: Smart, Sustainable, and High-Performance Coatings

The next decade will witness a major transformation in the metal coatings industry, powered by sustainability goals, digital manufacturing, and advanced materials science. AI-driven quality monitoring, smart pigments, and nanocoatings will redefine surface performance and lifecycle value.

With robust demand across construction, transportation, and energy sectors, the global metal coatings market is positioned for strong, sustained growth. Companies that align with eco-innovation, circular economy practices, and digital process optimization will lead the future of protective and decorative metal coatings—building a more resilient, efficient, and sustainable world.