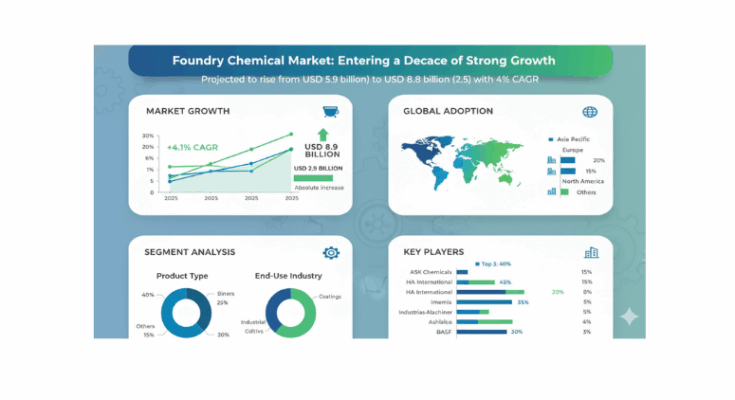

The Foundry Chemical Market is entering a decade of strong growth, projected to rise from USD 5.9 billion in 2025 to USD 8.8 billion by 2035, according to the latest Foundry Chemical Market Forecast and Outlook 2025–2035. This expansion represents an absolute increase of USD 2.9 billion at a compound annual growth rate (CAGR) of 4.1%, reinforcing the sector’s role in global industrial transformation. The Foundry Chemical Market is poised to expand nearly one and a half times over the forecast period, propelled by rising demand for advanced casting technologies, modernization of foundry operations, and the increasing adoption of sustainable chemical systems across key manufacturing industries.

The report underscores that the Foundry Chemical Market has become a central enabler of high-performance manufacturing. Foundries worldwide are adopting next-generation binders, coatings, and additives that optimize casting precision and improve operational efficiency while meeting stringent environmental standards. As the automotive and industrial machinery sectors intensify their focus on performance and sustainability, the Foundry Chemical Market is witnessing accelerated adoption of advanced formulation technologies that deliver superior mold strength, reduced defects, and enhanced productivity.

“Foundry chemicals have evolved from supportive materials into critical components of modern production strategy,” said a senior analyst from the research team. “The Foundry Chemical Market enables foundries to achieve cleaner, faster, and more accurate casting processes without the need for major infrastructure changes.”

A Decade of Consistent Growth

From 2025 to 2030, the Foundry Chemical Market is projected to climb from USD 5.9 billion to approximately USD 7.19 billion, accounting for nearly 45% of the total forecast growth. This initial phase will be marked by rapid adoption of binder and coating systems designed for precision casting, integration of automation technologies, and rising investment in smart manufacturing. Between 2030 and 2035, the Foundry Chemical Market is expected to add another USD 1.61 billion, driven by demand for eco-friendly chemicals and collaboration between chemical producers and foundry operators. Increasing emphasis on sustainability and cleaner production will shape the market’s competitive landscape throughout this decade.

Binders Dominate Market Share

Within the Foundry Chemical Market, the binders segment remains the dominant product category, commanding around 40% of global share in 2025. These high-performance materials—encompassing both organic and inorganic formulations—deliver superior mold strength and thermal stability across ferrous and non-ferrous applications. Coatings account for roughly 25% of the Foundry Chemical Market, offering advanced protection and enhanced surface quality for complex castings. Additives hold 20% of market share, while release agents and specialty chemicals together represent the remaining 15%.

Advancements in binder chemistry are transforming the Foundry Chemical Market, with innovations in multi-metal compatibility, emission reduction, and improved heat resistance driving performance gains. These developments allow foundries to maintain consistent casting quality while meeting global environmental regulations.

Ferrous Metals and Automotive Applications Lead Growth

The Foundry Chemical Market remains strongly anchored in the ferrous metal category, which represents about 60% of total usage due to the global dominance of iron and steel casting. Non-ferrous metals—led by aluminum, copper, and zinc—are rapidly expanding their role, reflecting broader industrial trends toward lightweight and corrosion-resistant materials.

End-use analysis reveals that the automotive industry accounts for 45% of the total Foundry Chemical Market, driven by rising vehicle production, precision component manufacturing, and lightweighting initiatives. Industrial machinery follows with 35%, while construction and other specialized sectors each contribute around 10%. The increasing sophistication of automotive and industrial manufacturing continues to stimulate innovation within the Foundry Chemical Market, as manufacturers demand chemicals that ensure precision, reliability, and environmental compliance.

Regional Expansion and Leadership

Asia Pacific remains the powerhouse of the Foundry Chemical Market, with India and China leading global expansion. India is forecast to record a 6.0% CAGR, supported by the government’s Make in India program and a rapidly growing automotive sector. Major foundry centers in Pune, Chennai, and Mumbai are integrating modern chemical systems to improve casting efficiency. China follows with a 5.0% CAGR, driven by its Made in China 2025 initiative and modernization of large-scale foundry facilities in Shanghai and Guangzhou.

Elsewhere, Mexico posts a 3.9% CAGR, benefiting from industrial growth and automotive production in Monterrey and Mexico City. In Europe, Germany maintains leadership through its precision manufacturing base and innovative approach to sustainable foundry technologies, advancing at a 3.6% CAGR. The United States, with 3.4% CAGR, continues to modernize its foundry infrastructure across Detroit, Chicago, and Houston, contributing significantly to the overall performance of the Foundry Chemical Market. South Korea and Japan sustain steady growth through integration of advanced manufacturing systems and digital casting solutions.

Competitive Landscape: Innovation Defines Leadership

The Foundry Chemical Market is moderately concentrated, with the top three companies—ASK Chemicals, HA International, and Imerys—collectively accounting for up to 40% of global market share. These leaders have built strong competitive positions through comprehensive product portfolios, technical expertise, and robust support networks. Other prominent players, including Vesuvius, Hüttenes-Albertus, ABP Induction, Sibelco, Ashland, Elkem, and BASF, continue to innovate in eco-friendly formulations and intelligent chemical systems.

Emerging manufacturers in high-growth regions such as India, China, and Eastern Europe are reshaping the Foundry Chemical Market through local production capabilities and rapid deployment of new technologies. Competitive differentiation increasingly depends on technological innovation, sustainability performance, and the ability to deliver integrated support services that enhance foundry productivity.

The Future of the Foundry Chemical Market

The next decade will see the Foundry Chemical Market evolve in tandem with global manufacturing transformation. Advanced chemical systems—capable of achieving 85–95% casting efficiency—are empowering foundries to improve quality while reducing environmental impact. Governments and industry associations are expected to accelerate this trend by promoting R&D incentives, cleaner production policies, and professional training for foundry specialists.

Ultimately, the Foundry Chemical Market stands at the intersection of technology, sustainability, and manufacturing progress. From the automotive hubs of Pune to the precision casting centers of Stuttgart, foundry chemicals are redefining industrial production—delivering cleaner processes, higher accuracy, and the foundation for the next generation of global manufacturing excellence.

About the Report

The Foundry Chemical Market Forecast and Outlook 2025–2035 provides comprehensive analysis across 40+ countries, detailing segmental performance, regional growth, and competitive trends. It covers products such as binders, coatings, additives, release agents, and others across ferrous and non-ferrous metals for automotive, industrial, and construction sectors. Key players profiled include ASK Chemicals, HA International, Imerys, Vesuvius, Hüttenes-Albertus, Sibelco, Ashland, Elkem, and BASF.

Browse Full Report : https://www.factmr.com/report/foundry-chemical-market