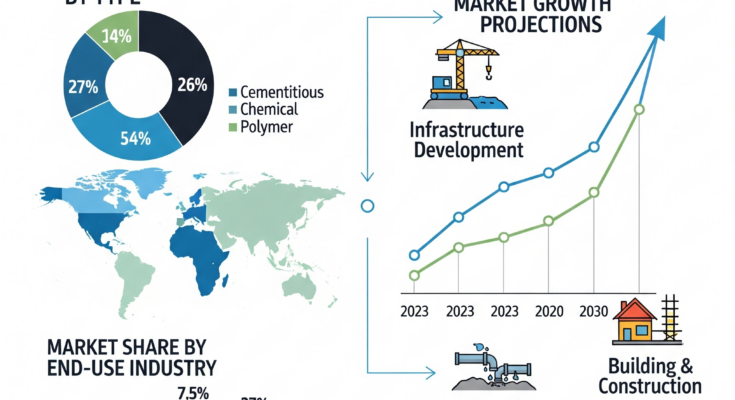

The global pumpable grouts market is poised for significant growth, with projections indicating its valuation will rise from USD 1,936 million in 2025 to USD 3,566 million by 2035, expanding at a compound annual growth rate (CAGR) of approximately 6.3% during the forecast period of 2025 to 2035. This robust trajectory is underpinned by accelerating developments in infrastructure construction, underground excavation, and the rising demand for high-performance materials within civil and geotechnical engineering sectors. Pumpable grouts have become indispensable in modern construction due to their adaptability, performance, and ability to meet complex engineering requirements.

Market Analysis by Type

The market is segmented into several key types, each serving unique applications. Cementitious grout remains the leading category, commanding the largest share thanks to its cost efficiency, compressive strength, and ability to be pumped in large volumes. These qualities make it a staple material in tunneling, mining, and large-scale infrastructure projects. Epoxy grout is gaining traction as well, driven by its durability and chemical resistance, which make it suitable for demanding industrial and marine applications. Polymethyl Methacrylate (PMMA) grouts are registering fast adoption due to their rapid-setting properties and adaptability, which allow them to address specialized, high-performance requirements in construction and repair.

Polyurethane grouts, known for their foam-like structure, are favored for soil stabilization, sealing, and void filling, particularly in projects involving ground stabilization and waterproofing. Acrylic-based grouts, although smaller in market share, fulfill critical roles in specialized repair and rehabilitation projects, contributing to the overall diversity of solutions available in the industry.

Market Analysis by Application

Pumpable grouts find widespread application across a variety of construction and industrial domains. Tunneling and shaft sinking represent the largest application area, particularly in metro rail projects, underground sewer construction, and large utility tunnels. The ability of cementitious grouts to travel long distances under pressure makes them the preferred choice in this segment. Mining is another major application, where polyurethane grouts are particularly valuable for void filling and ground consolidation. Their ability to seal unstable soil and stabilize geological formations ensures safe and efficient mining operations.

Other important applications include the construction of dams, reservoirs, and bridges, where grouts enhance stability and structural integrity. They are also widely used in soil stabilization projects, microtunneling, pipe jacking, and the development of marine and offshore structures. In renewable energy, pumpable grouts are increasingly used in wind turbine foundations, while railway and subway projects continue to drive demand in urban areas undergoing rapid transit expansion.

Market Analysis by Industry

The use of pumpable grouts extends across multiple industries. In the commercial and institutional building sector, they are essential in healthcare facilities, offices, hotels, and retail infrastructure, where durability and precision construction are crucial. The residential sector, including apartments and villas, also benefits from grout applications in structural reinforcement and waterproofing. Infrastructure and utilities remain dominant industries, with pumpable grouts supporting railway expansion, airport development, marine infrastructure, and energy projects. In the industrial sector, they play an equally important role across manufacturing, mining, and packaging, providing long-lasting solutions for challenging engineering environments. This wide-ranging applicability demonstrates the versatility and indispensability of pumpable grouts in both traditional and emerging markets.

Market Analysis by Region

Regional trends further highlight the diversity of growth patterns. In North America, the market is driven by the need to rehabilitate aging infrastructure, including tunnels, bridges, and water systems. Increasing investments in modernization and the adoption of premium formulations underscore the demand for durable and sustainable grouts in this region. Western Europe represents another strong market, where countries such as Germany, France, and the United Kingdom are leading in urban transportation and tunneling initiatives, particularly under sustainability and environmental mandates.

Asia-Pacific is projected to be the fastest-growing region, with China and India at the forefront. India, in particular, is expected to expand at a rapid pace, supported by large-scale infrastructure programs such as Smart Cities, metro rail networks, and the Bharatmala highway scheme. Mining operations also contribute to its demand for pumpable grouts. China follows closely with significant investment in urbanization, industrial construction, and eco-friendly formulations. In Latin America, the Middle East, and Africa, growth is spurred by the development of mining, water infrastructure, and energy projects, where challenging geological conditions create opportunities for grout applications.

Competitive Landscape and Recent Developments

The competitive landscape of the pumpable grouts market is defined by a mix of global leaders and regional specialists. Prominent players such as Sika AG, BASF SE, Mapei S.p.A., Fosroc International, Five Star Products, SealBoss Corp., Avanti International, Isomat S.A., Myk Laticrete, and Saint-Gobain Weber are shaping the market through a combination of technological innovation, product diversification, and regional expansion strategies. These companies focus heavily on research and development to deliver advanced grout formulations that meet rising standards for sustainability, performance, and safety.

Recent developments underscore this trend. Mapei S.p.A. has demonstrated significant progress in innovation by developing thousands of new formulations and qualifying hundreds of raw materials in recent years, highlighting its commitment to sustainability and next-generation solutions. Sika AG has announced the expansion of its production capacity in North America with a new large-scale mortar plant in New Jersey, reflecting its strategy to meet regional demand and shorten supply chains. Such moves illustrate the emphasis on technological advancement, capacity building, and eco-friendly product offerings that will shape competition in the coming decade.

Conclusion

The pumpable grouts market stands at a pivotal juncture, supported by the twin forces of infrastructure modernization in developed regions and rapid construction activity in emerging economies. Innovations in grout types, from cementitious and epoxy to polyurethane and PMMA, are ensuring that the industry can meet increasingly complex application demands. Key players are strengthening their positions through innovation and expansion, while regional specialists are carving niches in high-demand markets. With the market expected to achieve a valuation of USD 3,566 million by 2035, up from USD 1,936 million in 2025, and a steady CAGR of 6.3%, the industry is primed for robust, technology-driven growth well into the next decade