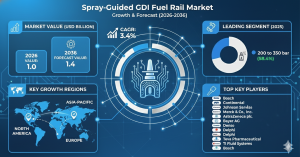

As automotive manufacturers accelerate the transition toward cleaner, more fuel-efficient powertrains, gasoline direct injection (GDI) technology continues to gain prominence. Within this ecosystem, spray-guided GDI fuel rails play a critical role by enabling precise fuel delivery directly into the combustion chamber. The spray-guided configuration, in particular, enhances combustion efficiency by optimizing fuel atomization and mixture formation. This has positioned the spray-guided GDI fuel rail market as an essential component of next-generation internal combustion engines, especially as emissions regulations tighten and performance expectations rise globally.

Market Overview

Spray-guided GDI fuel rails are engineered to support high-pressure fuel delivery while maintaining accurate control over injection timing and spray patterns. Unlike wall-guided or air-guided systems, spray-guided designs place the injector centrally, allowing fuel to be injected directly toward the spark plug. This configuration improves combustion stability, reduces fuel wall wetting, and supports lean-burn strategies.

The market is driven by increasing demand for downsized engines, improved fuel economy, and compliance with stringent emission standards. Automakers are increasingly integrating spray-guided GDI systems into passenger vehicles to balance performance with regulatory compliance. In parallel, fuel rail manufacturers are focusing on material innovations, compact designs, and enhanced durability to withstand extreme pressure and temperature conditions within modern engines.

Technology and Design Evolution

Technological advancements are shaping the evolution of spray-guided GDI fuel rails. Manufacturers are adopting advanced alloys and stainless-steel materials to improve corrosion resistance and pressure tolerance. Precision manufacturing techniques such as laser welding and high-accuracy machining are being used to ensure leak-free performance and consistent fuel flow.

Additionally, integration with electronic engine management systems has become more sophisticated. Modern spray-guided fuel rails are designed to work seamlessly with sensors and control units, enabling real-time adjustments in fuel delivery. This integration supports improved throttle response, reduced particulate emissions, and optimized combustion across varying driving conditions.

Regional Insights

The adoption of spray-guided GDI fuel rail systems varies by region, influenced by automotive production volumes, emission regulations, and technological readiness.

North America remains a strong market due to widespread adoption of advanced gasoline engines and continuous innovation by major automotive OEMs. Europe follows closely, driven by strict environmental standards and a strong focus on efficiency-oriented engine designs. Automakers in the region are increasingly deploying spray-guided GDI systems to meet emissions targets without compromising driving performance.

The Asia-Pacific region is emerging as a key growth area, supported by expanding vehicle production, rising consumer demand for fuel-efficient vehicles, and ongoing investments in automotive manufacturing infrastructure. Countries with strong domestic automotive industries are increasingly adopting GDI technologies to remain competitive in both local and export markets.

Key Market Trends

Several trends are shaping the spray-guided GDI fuel rail market landscape. One notable trend is the growing emphasis on particulate emission reduction. Spray-guided systems offer improved control over fuel dispersion, helping automakers address particulate matter concerns associated with direct injection engines.

Another trend is the shift toward modular fuel rail designs. Modularization allows manufacturers to adapt fuel rails to different engine platforms more efficiently, reducing development time and production costs. This flexibility is particularly valuable as automakers diversify engine portfolios to meet varying regulatory and consumer demands.

Collaboration across the automotive supply chain is also increasing. Fuel rail manufacturers are working closely with injector suppliers, engine designers, and OEMs to co-develop optimized systems that enhance overall engine performance.

Applications and End-Use Outlook

The primary application of spray-guided GDI fuel rails is in passenger vehicles, where demand for improved fuel economy and driving dynamics remains strong. These systems are especially well-suited for compact and mid-sized vehicles that rely on downsized engines with turbocharging.

In addition to passenger cars, certain light commercial vehicles are beginning to adopt spray-guided GDI configurations to achieve better efficiency and lower emissions. As regulatory frameworks continue to evolve, adoption across a broader range of vehicle segments is expected.

The aftermarket also presents opportunities, particularly for replacement components and performance-oriented upgrades. However, the market remains largely OEM-driven due to the complexity and precision required in spray-guided fuel rail systems.

Competitive Landscape

The spray-guided GDI fuel rail market is characterized by the presence of established automotive component manufacturers with strong engineering capabilities. Competition is driven by product reliability, precision manufacturing, and the ability to meet evolving OEM requirements. Continuous research and development efforts are essential for maintaining competitiveness, particularly as engine technologies advance.

Manufacturers are also focusing on global expansion strategies, establishing production facilities closer to major automotive hubs to improve supply chain efficiency and customer responsiveness.

Conclusion

The spray-guided GDI fuel rail market is a vital segment within the broader automotive fuel system landscape. As automakers strive to balance performance, efficiency, and environmental compliance, spray-guided GDI technology offers a compelling solution. Continued innovation in materials, design, and system integration will be critical to sustaining market growth.

Access to in-depth market intelligence, such as comprehensive analyses published by leading research firms like Fact.MR, can help stakeholders navigate technological shifts and competitive dynamics. For manufacturers, suppliers, and investors, understanding the evolving role of spray-guided GDI fuel rails is essential to capitalizing on opportunities in the future of advanced engine systems.

Browse Full Report – https://www.factmr.com/report/spray-guided-gdi-fuel-rail-market