The flame-retardant polyamide compounds for EV powertrain and battery market is projected to experience strong growth over the next decade as the global electric vehicle (EV) industry expands and material safety requirements become more stringent. Flame-retardant polyamide compounds are high-performance engineered polymers that combine excellent mechanical properties with enhanced resistance to ignition, flame spread, and high temperatures. These materials are increasingly specified for critical EV components, including battery enclosures, powertrain housings, connectors, and thermal management systems, where electrical safety, durability, and fire protection are essential.

With EV adoption gaining momentum across major automotive markets and battery safety standards evolving rapidly, demand for flame-retardant thermoplastics that enable lightweight construction, enhanced performance, and compliance with regulatory requirements is on the rise.

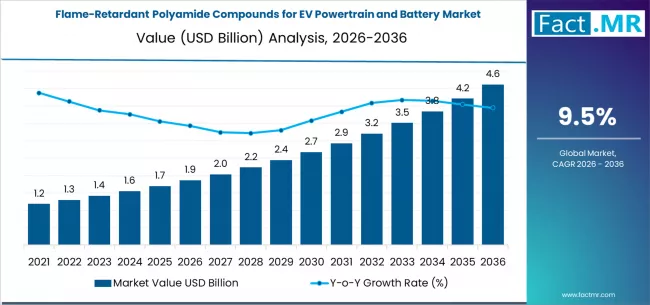

Market Forecast (2026–2036)

-

Market Value (2026): USD 2.15 billion

-

Market Forecast Value (2036): USD 6.49 billion

-

Forecast CAGR (2026–2036): 10.9%

-

Leading Compound Type: Halogen-free flame-retardant polyamide systems

-

Key End Uses: Battery housings, powertrain components, electrical connectors, thermal shields

-

Primary Growth Regions: Asia Pacific, Europe, North America

To access the complete data tables and in-depth insights, request a Discount On The Report here: https://www.factmr.com/connectus/sample?flag=S&rep_id=13017

Market Overview

Flame-retardant polyamide compounds are engineered thermoplastic materials formulated with specialized flame-retardant additives and reinforcing agents. These compounds are designed to meet demanding performance criteria, including high thermal stability, mechanical strength, impact resistance, and electrical insulation properties. In electric vehicles, they play a crucial role in enhancing safety by inhibiting ignition and flame propagation in high-temperature or fault conditions.

Compared with traditional polyamides, flame-retardant grades offer superior fire performance while maintaining the structural integrity required for powertrain housings, battery enclosures, and high-voltage electrical components. As battery voltage ratings increase and power electronics become more compact and thermally challenging, the requirement for advanced flame-retardant materials continues to intensify.

Key Market Drivers

1. Rapid Electric Vehicle Adoption

The global transition to electric mobility remains the principal driver for flame-retardant polyamide compounds. EV production is expanding rapidly, supported by government incentives, emission reduction mandates, and growing consumer preference for clean transportation. As OEMs seek to improve range, efficiency, and safety, advanced materials that deliver high performance and flame resistance are becoming indispensable.

2. Stringent Safety and Regulatory Standards

Regulatory requirements for automotive safety, particularly related to fire resistance and battery safety, are becoming more rigorous. Safety standards and testing protocols increasingly mandate materials that can withstand thermal runaway events or high-energy system failures. Flame-retardant polyamide compounds offer critical performance features that help vehicle manufacturers meet or exceed these standards.

3. Weight Reduction and Performance Optimization

Lightweight materials are essential to improving EV efficiency and extending driving range. Flame-retardant polyamides offer an advantageous strength-to-weight ratio compared with metal alternatives, supporting overall vehicle light-weighting strategies without compromising safety or performance.

4. Increased Integration of High-Voltage Components

EV powertrain and battery systems feature complex, high-voltage components that generate heat under normal and fault conditions. Components such as battery enclosures, power distribution units, inverters, and electrical connectors require materials with both thermal management capabilities and flame resistance. Flame-retardant polyamide compounds meet these multifaceted performance demands.

Market Segmentation Insights

By Compound Type

-

Halogen-Free Flame-Retardant Polyamide Compounds: Lead the market due to environmental and regulatory preference, reduced toxic emissions, and strong performance profiles.

-

Halogenated Flame-Retardant Polyamide Compounds: Used where high flame resistance is required and regulatory environments permit.

-

Mineral-Filled and Reinforced Compounds: Provide enhanced structural strength and stiffness for load-bearing parts.

-

Specialty Nanocomposite and Hybrid Formulations: Offer tailored properties for advanced thermal or electrical management.

By Application

-

Battery Enclosures and Housing: Largest segment due to critical safety and thermal management needs in EV battery systems.

-

Powertrain Structural Components: Include motor housings and transmission covers where mechanical strength and fire resistance are essential.

-

Electrical Connectors and High-Voltage Interfaces: Demand high flame resistance and insulation properties.

-

Thermal Management Systems: Used in cooling jackets, ducting, and shields to combine thermal control with fire safety.

-

Interior and Auxiliary Components: Supplementary applications where flame retardancy enhances overall safety.

Regional Demand Dynamics

Asia Pacific

Asia Pacific is expected to capture significant share of the market growth through 2036, supported by large EV production hubs in China, increasing electrification in India, and strong automotive manufacturing ecosystems in Japan and South Korea. Continued investments in EV infrastructure and material innovation further enhance market prospects in the region.

Europe

Europe exhibits strong growth driven by stringent vehicle safety standards, ambitious CO₂ emissions targets, and widespread adoption of EVs. Major automotive producers in Germany, France, and other European countries are advancing material solutions for next-generation electric vehicles, reinforcing demand for flame-retardant polyamide compounds.

North America

North America remains a key regional market, buoyed by expanding domestic EV manufacturing, supportive federal and state incentives, and growing adoption of high-performance materials in automotive applications. The focus on battery safety and advanced materials in the United States and Canada supports continued market expansion.

Competitive Landscape

The flame-retardant polyamide compounds market is characterized by competition among global chemical manufacturers, engineering polymer specialists, and materials innovators. Key players are investing in research and development to enhance flame retardancy, improve thermal performance, and expand material portfolios tailored to specific applications.

Strategic initiatives include development of halogen-free formulations, partnerships with automotive OEMs and tier suppliers, and expansion of regional production capabilities to support localized supply chains. Providing technical support for material qualification and integration into high-volume manufacturing processes is also a critical competitive advantage.

Future Outlook

The flame-retardant polyamide compounds for EV powertrain and battery market is expected to maintain robust growth through 2036 as electric vehicle adoption accelerates and performance requirements evolve. Continued innovation in polymer chemistry, coupled with rising safety standards and the push for lightweight, high-performance materials, will drive broader use of flame-retardant polyamide solutions.

As EV manufacturers strive for higher safety margins, better energy efficiency, and enhanced durability, flame-retardant polyamide compounds will remain key enabling materials that bridge performance, protection, and sustainability in next-generation electric vehicles.

Browse Full Report: https://www.factmr.com/report/flame-retardant-polyamide-compounds-for-ev-powertrain-and-battery-market