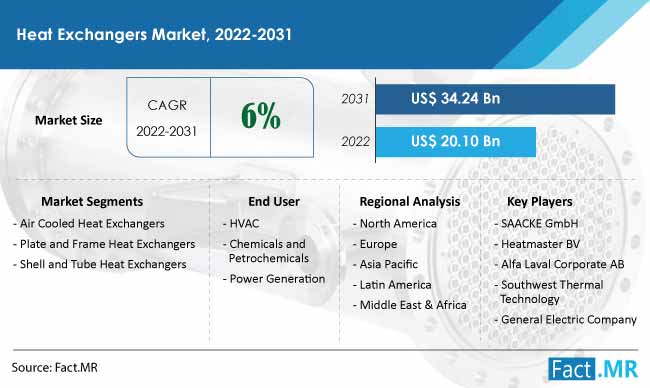

As per industry analysis by Fact.MR, a market research and competitive intelligence provider, the global heat exchangers market is anticipated to rise at a CAGR of 6% from 2022 to 2031.

The market is likely to be driven by rising chemical industry demand, new inventions, and growing focus on improving efficiency requirements over the coming years. Majority of operations in petrochemical plants involve heat and pressure, demanding heat transfer efficiency and energy savings, which is projected to increase demand for energy-efficient heat exchangers.

The primary reason for rising demand for heat exchangers is to maximize thermal efficiency. Rapidly increasing chemicals and hydrocarbon sectors, as well as various prospective mega power projects, are expected to drive increased demand for heat exchangers.

Growing number of nuclear reactors in emerging countries around the world is providing significant income potential for heat exchanger manufacturers. For a nuclear power plant, heat exchangers provide overall efficiency and power output.

Key Takeaways from Market Study

- Global heat exchangers market to reach valuation of US$ 34.24 billion by 2031.

- Market in Europe accounts for 35% share of global market.

- Demand for shell and tube heat exchangers expected to rise significantly over forecast period.

“Rising penetration of renewable energy technologies, increased investments in power plants, renovation of existing nuclear facilities, and development of new nuclear power plant projects are all creating opportunities for heat exchanger manufacturers around the world,” says a Fact.MR analyst

Winning Strategy

Key players in the market are investing heavily in research and development to improve device efficiency. New product creation, diversification, mergers & acquisitions, and global expansion are all strategies used by manufacturers. These techniques help businesses grow their market penetration and respond to changing technological demands from a variety of industries.

For instance,

- In 2020, Danfoss introduced a world-first series of microplate heat exchangers for moderate, alternative refrigerants to help with the transition to reduced GWP refrigerants and improved efficiency. For OEMs moving to lower GWP refrigerants that utilize a screw and rotational compression, modern technology has overcome the design challenge.

| Key Companies Profiled |

|